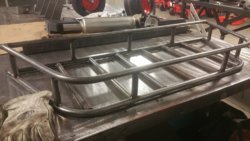

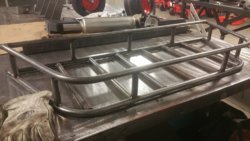

I figured since I've already introduced myself in another thread, I'd go ahead and jump right in and start my own build thread as well. As the title states, the goal of this build is for me to do as much of my own fabrication as possible. I'm not a hardcore mudder/offroader like a lot of you guys, so don't expect anything too crazy. But I do need my rig to be able to haul a lot (both stuff and people), drag a carcass out of the woods, and still be reliable as a moderate trail rig. My current list is more lights, more storage, more traction, and more comfort (in no particular order). The good news is that I work as an R&D fabricator and have access to some really cool toys. I've got sheet metal brakes, sheet metal and tubing lasers, mills, mandrel benders, and a full CAD system at my disposal. The bad news is that it's tough to get time on these machines right now since it's our busy season and we're running behind on our production line. My first project that I'm tackling is going to help with storage. I haven't seen a good affordable option when it comes to racks for these rigs, so I decided to fabricate my own. I wanted a rear rack that would mount in the receiver hitch, and then come up to nearly bed height for ground clearance. So I grabbed a couple sticks of 3/4" round tube and run them through the mandrel bender to build a frame. I bent them so that the edge against the frame is wider than the tail. The bed side of the frame is about 41.5" wide, and the tail is about 32" roughly. I didn't want to run the risk of hanging a corner of the rack in tight turns, so I tapered them in about 5" on each side. I also wanted the tail lights to still be visible on either side of the rack of someone is behind me. Inner basket dimensions are about 14"Lx4"D. I wanted it just large enough to put a small to medium sized cooler in there with enough room for a day bag or other small gear. Right now it's just tacked up until I can run it out to the house and test fit it, and then get some height measurements to the receiver hitch. Only thing I'm thinking about adding is a plate to the backside (sort of like a Jeep) to mount a spare tire/rim to just in case. I'm trying to keep it somewhat light so my wife can handle it if need be as well. What do you guys think so far?

Last edited by a moderator: