Code54

Well-Known Member

Lifetime Member

Club Contributor

This is a a basic guide to checking and adjusting the valves but please do so at your own risk as I am not a Honda Mechanic and am putting this up for informational purposes only

Most of the Tools needed:

1) Flat head screwdriver

2) Flashlight

3) 10mm box wrench

4) 6mm Allen head socket

5) Crescent wrench

6) Feeler gauge

7) Sparkplug wrench

8) Dental mirror

9) Phillips Screw driver

10) Torque wrench

Honda recommends a valve adjustment at the first 100 miles or 20 hours, and every 600 miles/100 hours after that.

It is a good idea to wash your machine before you start just so there is less mud to fall into places where you don’t want dirt and mud (the valves, inspections hole, etc)

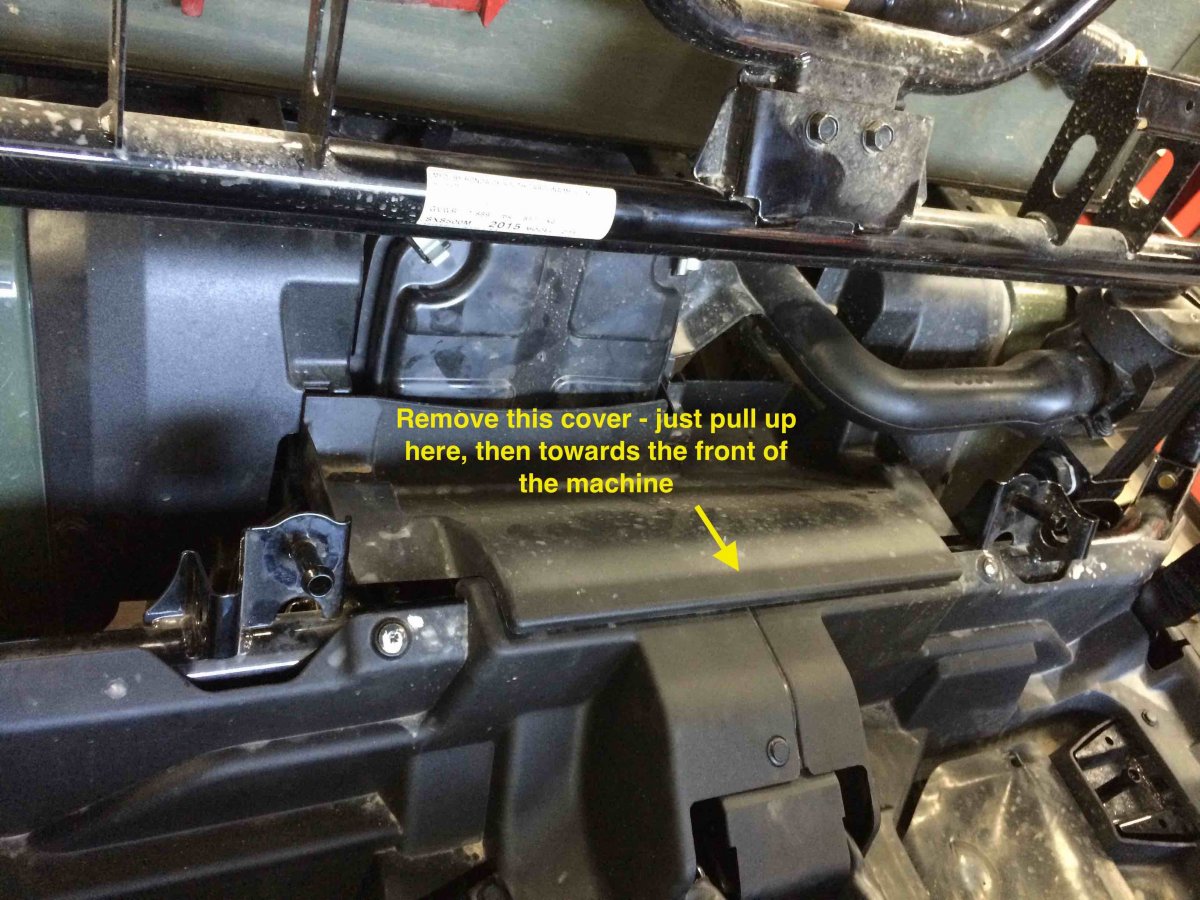

I took a bunch of photos to give you some idea what is involved so please see below

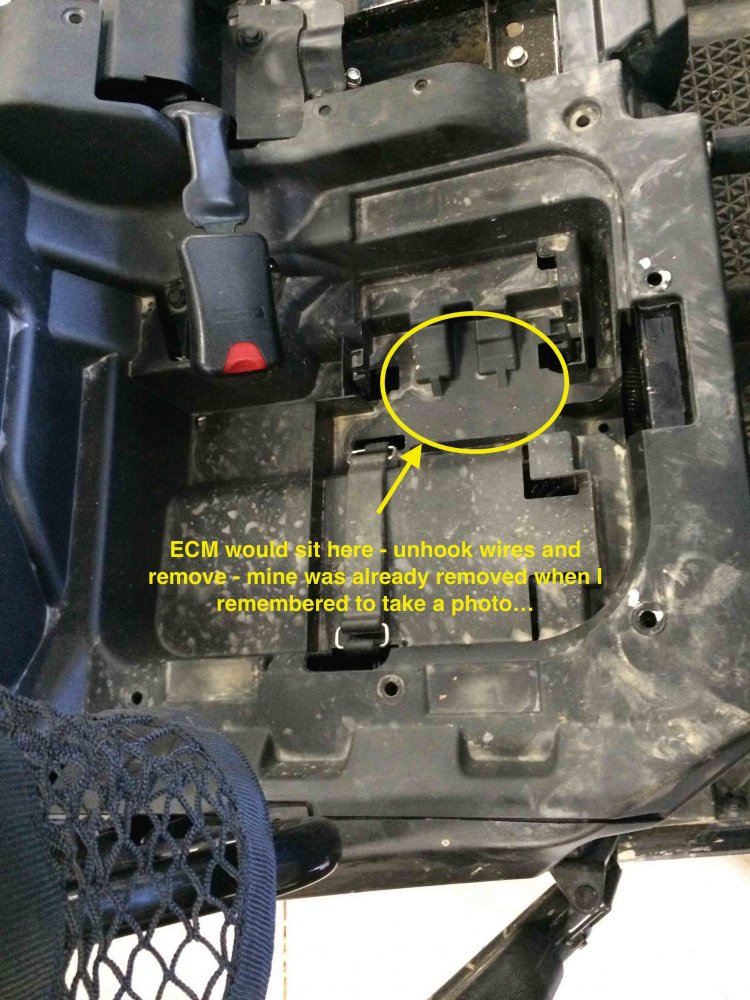

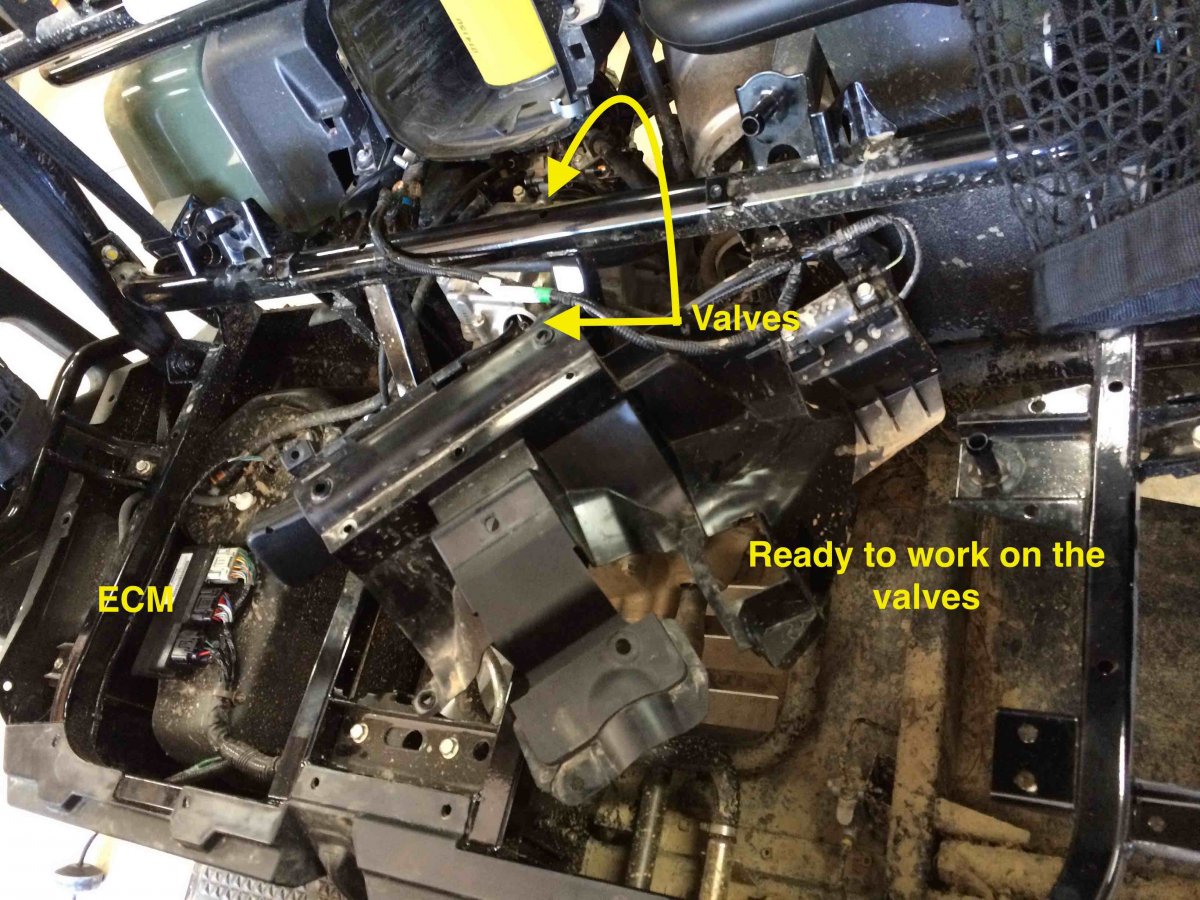

I forgot to take a photo before I removed my ECM but if you unplug it you can move it out of the way and make things a bit easier on yourself

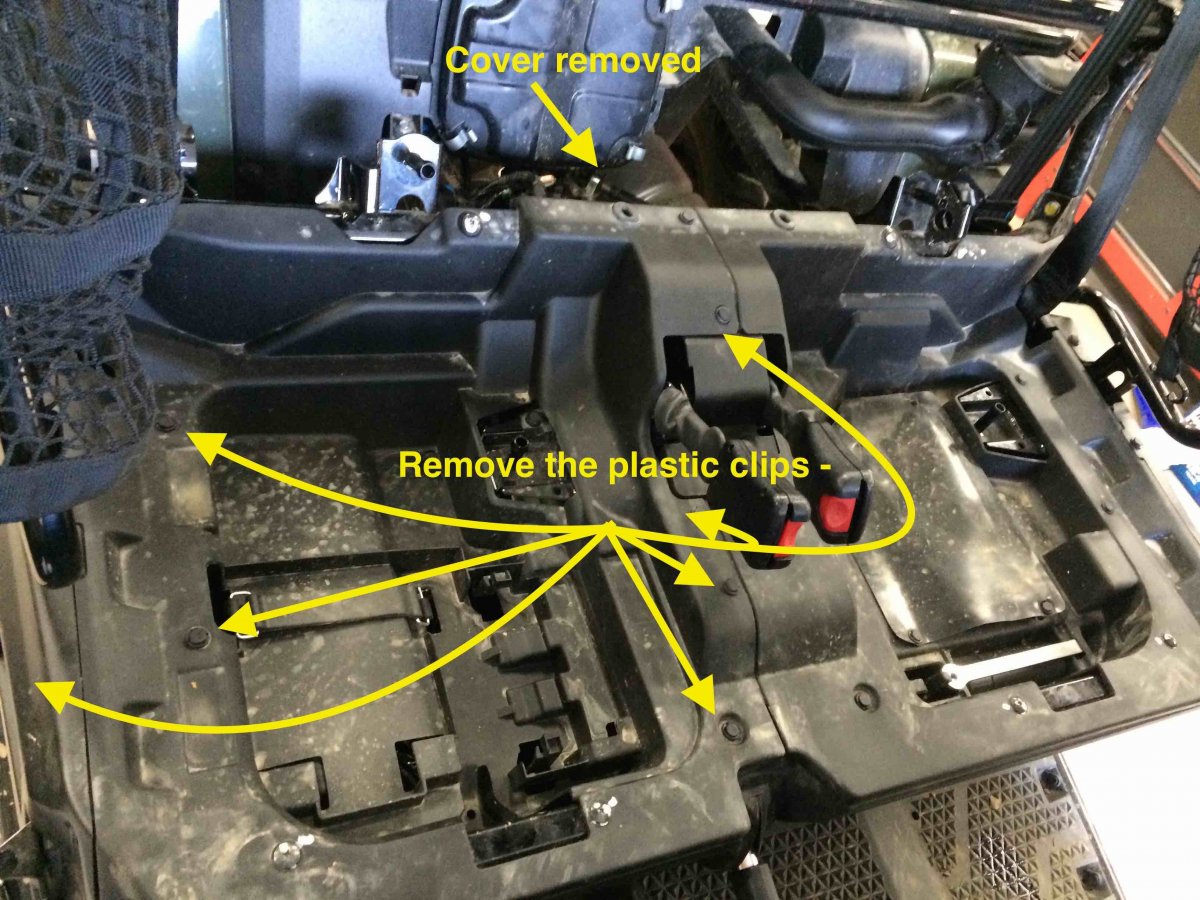

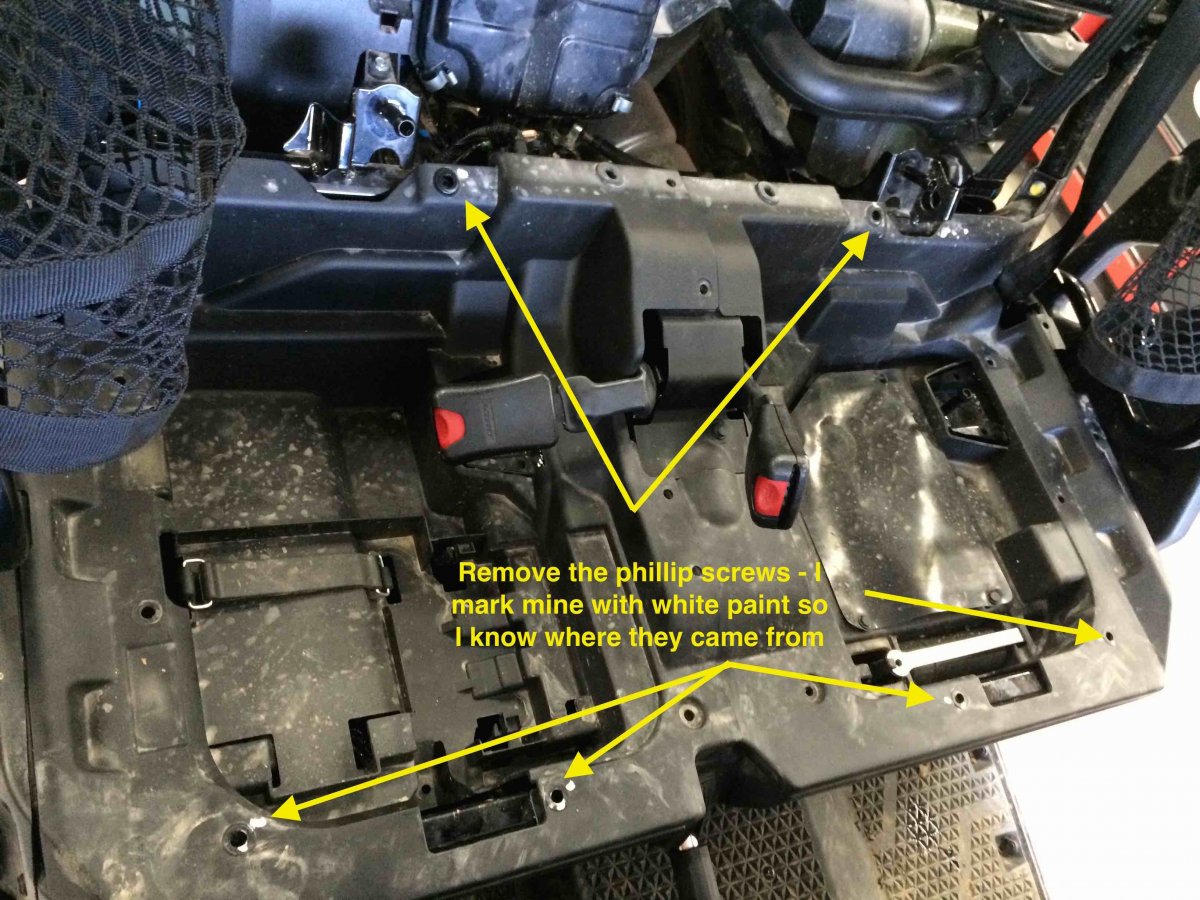

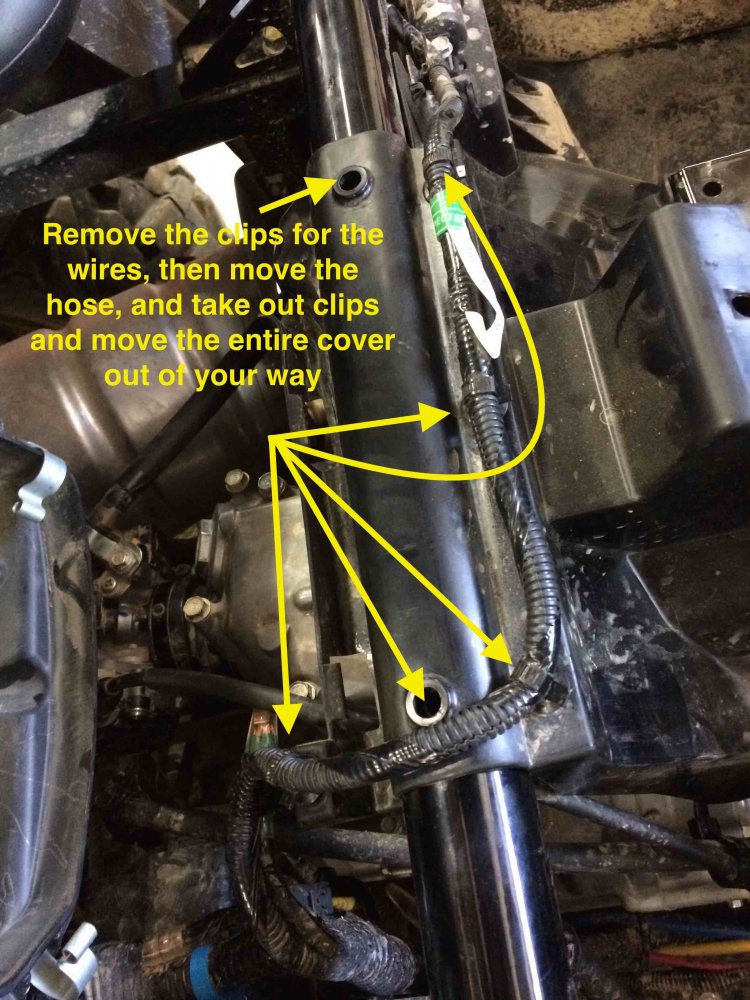

Do this to both panels - left and right

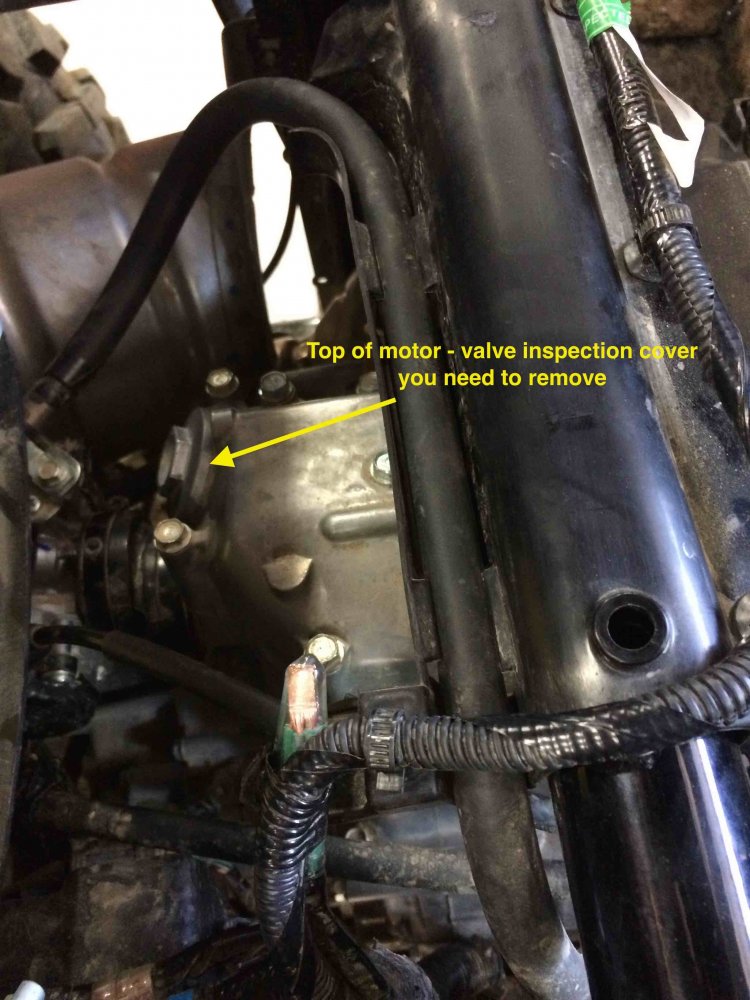

Now unthread the seatbelt from the plastic covers and remove the plastic that was under the seats and move the plastic (photo above) cover that held the wires out of the way. Don't really need to fully remove it, just get it so you can work on the valves.

Go ahead and remove the spark plug - you need it gone to find Top Dead Center and to release some of the engines compression. Don't try to find TDC yet - you are just getting ready to.

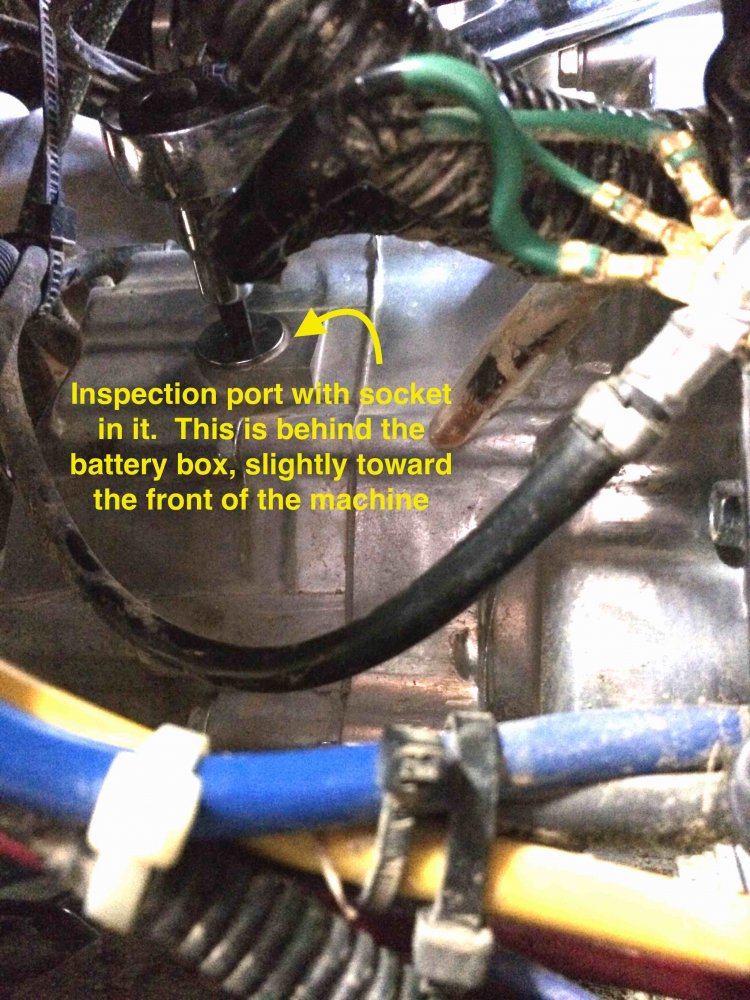

This gives you a little room to see the inspection port (Flywheel TDC "T" mark)

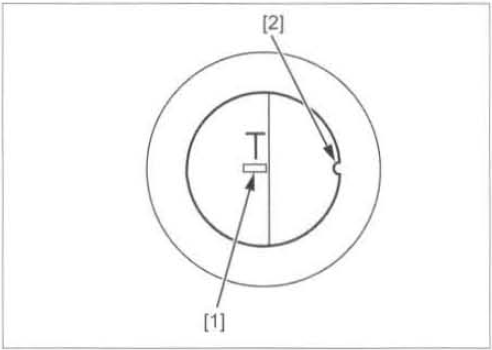

Due to the very tight work area I could not get a photo of what it looks like inside (on the flywheel) of the "T" you are looking for but it is basically a T with a line

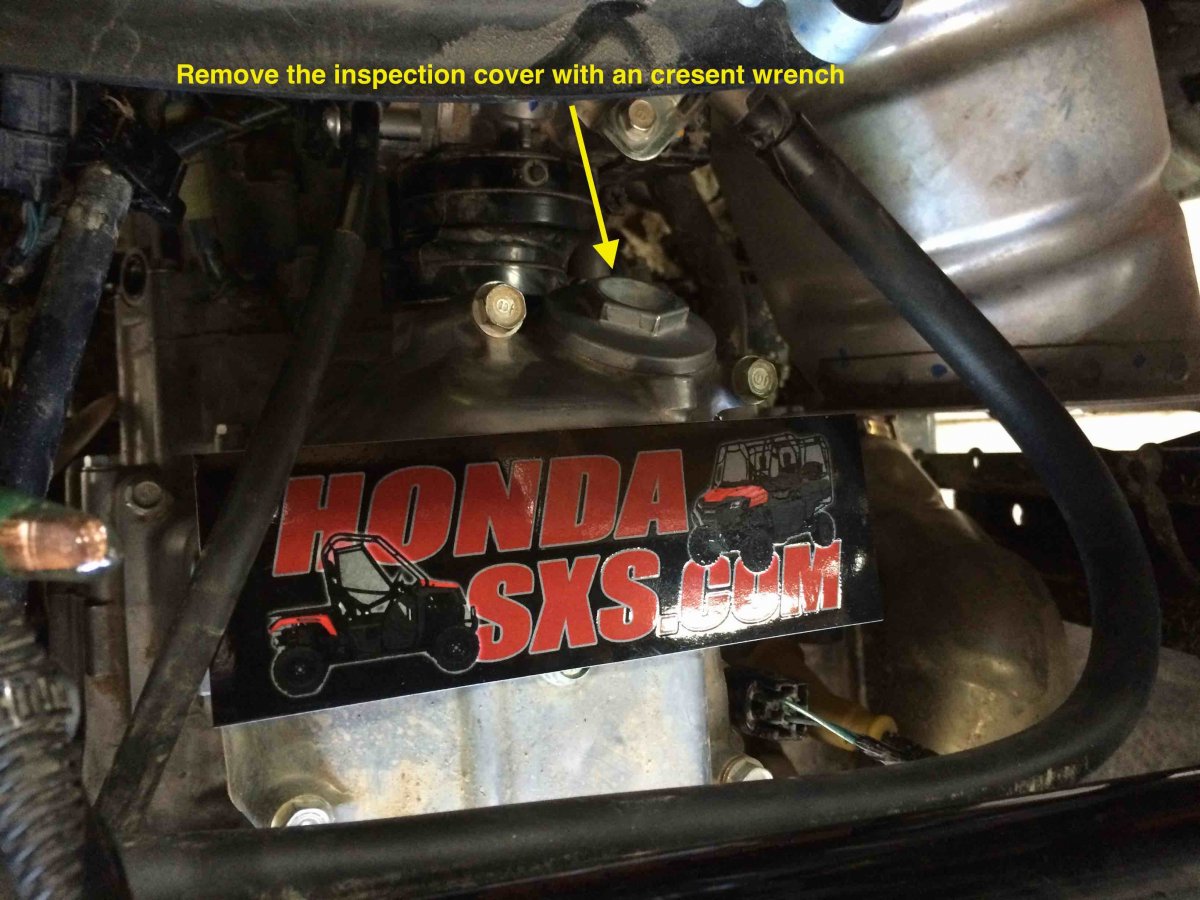

You will need to remove both the covers. The one is in the photo and there is the 2nd one that is below the sticker (Cant see it in the photo but it looks the same and also gets removed -see the next photo)

While you have the cover off make sure it is clean and the O ring is intact and has a light coat of oil

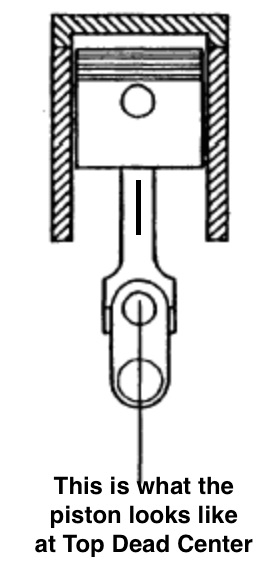

Now is when you find TDC

Finding top dead center (TDC) on this machine is a real PAIN because of the way the motor is located so be prepared. To adjust the valves you have to have a COLD engine (think Honda says below 95F.

There are several ways to find TDC but first remove the spark plug and get a flashlight.

1) Stick a straw in the sparkplug hole and wait until it hits the high point where there is no pressure on the valves (it works but is not the best)

2) Use a wrench to turn the motor over and watch in the inspection port for the “T” on the flywheel to know you hit TDC – really the best way

3) Put the machine in 5th gear, look into the inspection port and SLOWLY roll it forward until you see the “T”. This is what I did. It is extremely hard to see the marks but it can be done.

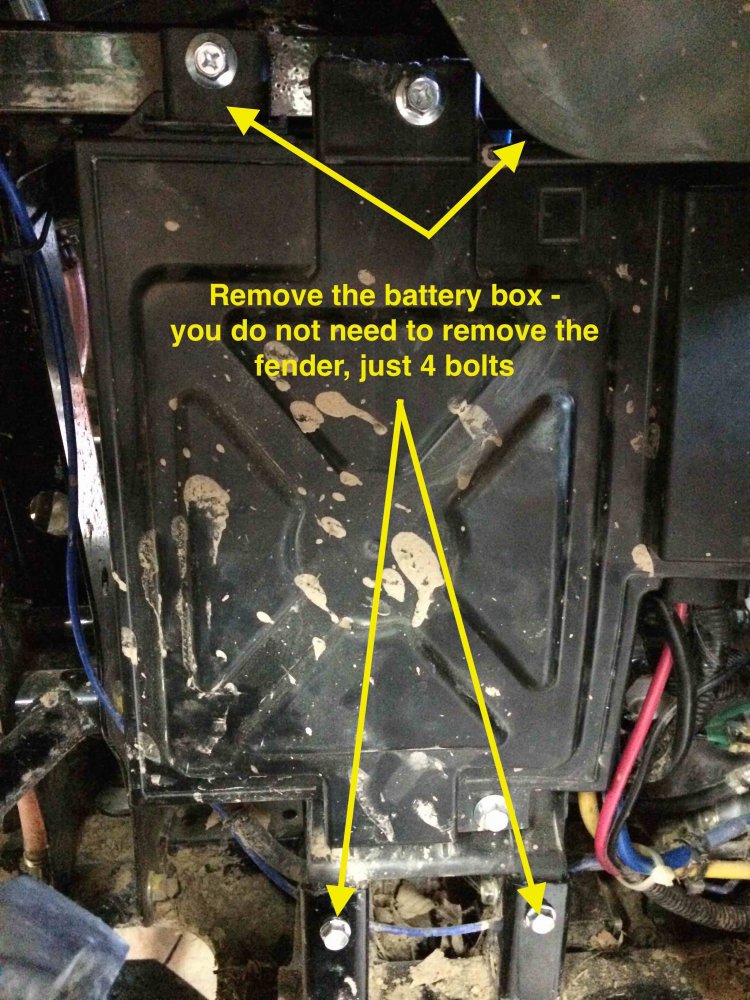

To see in the inspection port I had to use a dental mirror (inspection mirror would have been better), flashlight and some very uncomfortable positions. If you remove the rear passenger wheel and the battery box you maybe able to see it more clearly without using a dental mirror but it will take some extra work to get to that point.

If you miss the “T” you have to do a full cycle to get back to it, you can’t just roll the machine backwards. Basically if you miss it, just start over. If you have your inspection/adjustment ports off when you push the machine you can see them opening and closing so you can gauge about when you are going to hit TDC. If you try to insert the gauge (and you see the piston is at TDC) and there is NO room for it to fit in you are most likely in the exhaust stroke – keep going. Never turn the engine backwards, just restart if you miss it.

-(Sorry could not take photos and move the machine, watch the valves, watch piston and check for the "T" in the inspection port with a mirror and flashlight and take photos - Sorry I'm not that coordinated..... LOL)

This image is what are looking for inside the inspection hole.

Once you have TOP DEAD CENTER look at the valves

Here is a photo I found on the net that shows how to measure the clearance (Photo is not a Pioneer but the idea is the same).

.006 is the correct valve clearance + or - .001

When adjusting the valves you need to slide the feeler gauge in and when you pull it out there will be a little resistance but it is not hard to pull it out. I have had it described to me as the amount of pressure would be similar to removing a sheet of paper from a closed book. Sort of a little bit of drag as you remove it but not needing a hard pull.

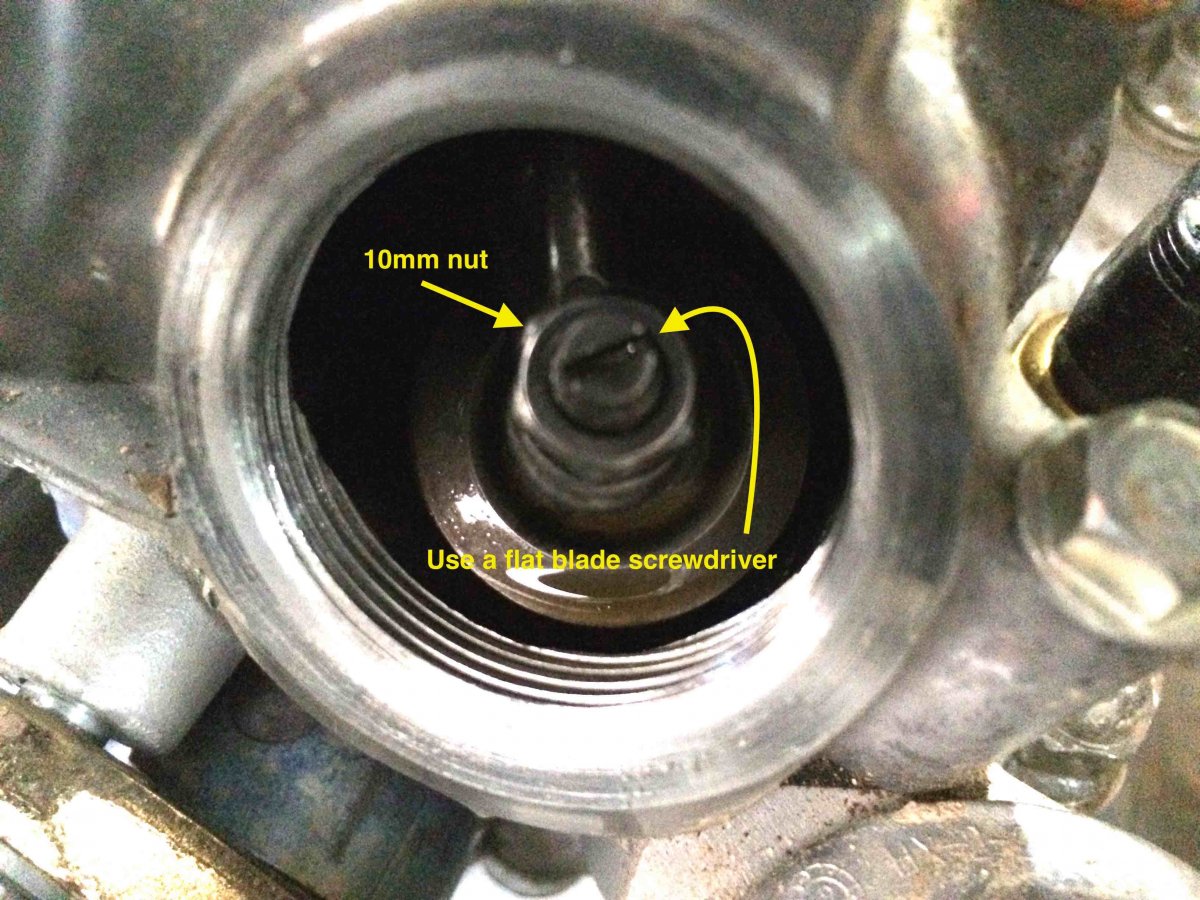

Measure your clearance (Please see above on how to do this - .006 is the correct intake valve clearance + or - .001, and .009 exhaust) and if it is too loose or to tight you need to loose the nut, and turn the slotted tappet. Remeasure and when you get it correct tight the nut down. The torque setting is 13 lbf.ft. DO NOT OVER TIGHTEN this nut as they can strip. Also once you get everything snugged up recheck your measurements as things can change a little as you get everything locked down. It does not take much of a turn of the tappet to change the clearance of the valve so always check and recheck everything.

Here is what it looks like when you are adjusting them

.006 is the correct intake valve clearance + or - .001

Mine was dead on .006/.009 so I didn't have to adjust mine - you may or may not have to so I staged this photo just for reference. Anyway, once everything is set correctly it is time to put the covers back on the valves, replace the inspection port cover, reattach the battery box, and put the plastic back in place along with the ECM.

That is really all there is to adjusting the valves. If things were easier to get to it would be a ten minute job - really the hardest thing is making sure you are at TDC, after that everything is accessible.

Most of the Tools needed:

1) Flat head screwdriver

2) Flashlight

3) 10mm box wrench

4) 6mm Allen head socket

5) Crescent wrench

6) Feeler gauge

7) Sparkplug wrench

8) Dental mirror

9) Phillips Screw driver

10) Torque wrench

Honda recommends a valve adjustment at the first 100 miles or 20 hours, and every 600 miles/100 hours after that.

It is a good idea to wash your machine before you start just so there is less mud to fall into places where you don’t want dirt and mud (the valves, inspections hole, etc)

I took a bunch of photos to give you some idea what is involved so please see below

I forgot to take a photo before I removed my ECM but if you unplug it you can move it out of the way and make things a bit easier on yourself

Do this to both panels - left and right

Now unthread the seatbelt from the plastic covers and remove the plastic that was under the seats and move the plastic (photo above) cover that held the wires out of the way. Don't really need to fully remove it, just get it so you can work on the valves.

Go ahead and remove the spark plug - you need it gone to find Top Dead Center and to release some of the engines compression. Don't try to find TDC yet - you are just getting ready to.

This gives you a little room to see the inspection port (Flywheel TDC "T" mark)

Due to the very tight work area I could not get a photo of what it looks like inside (on the flywheel) of the "T" you are looking for but it is basically a T with a line

You will need to remove both the covers. The one is in the photo and there is the 2nd one that is below the sticker (Cant see it in the photo but it looks the same and also gets removed -see the next photo)

While you have the cover off make sure it is clean and the O ring is intact and has a light coat of oil

Now is when you find TDC

Finding top dead center (TDC) on this machine is a real PAIN because of the way the motor is located so be prepared. To adjust the valves you have to have a COLD engine (think Honda says below 95F.

There are several ways to find TDC but first remove the spark plug and get a flashlight.

1) Stick a straw in the sparkplug hole and wait until it hits the high point where there is no pressure on the valves (it works but is not the best)

2) Use a wrench to turn the motor over and watch in the inspection port for the “T” on the flywheel to know you hit TDC – really the best way

3) Put the machine in 5th gear, look into the inspection port and SLOWLY roll it forward until you see the “T”. This is what I did. It is extremely hard to see the marks but it can be done.

To see in the inspection port I had to use a dental mirror (inspection mirror would have been better), flashlight and some very uncomfortable positions. If you remove the rear passenger wheel and the battery box you maybe able to see it more clearly without using a dental mirror but it will take some extra work to get to that point.

If you miss the “T” you have to do a full cycle to get back to it, you can’t just roll the machine backwards. Basically if you miss it, just start over. If you have your inspection/adjustment ports off when you push the machine you can see them opening and closing so you can gauge about when you are going to hit TDC. If you try to insert the gauge (and you see the piston is at TDC) and there is NO room for it to fit in you are most likely in the exhaust stroke – keep going. Never turn the engine backwards, just restart if you miss it.

-(Sorry could not take photos and move the machine, watch the valves, watch piston and check for the "T" in the inspection port with a mirror and flashlight and take photos - Sorry I'm not that coordinated..... LOL)

This image is what are looking for inside the inspection hole.

Once you have TOP DEAD CENTER look at the valves

Here is a photo I found on the net that shows how to measure the clearance (Photo is not a Pioneer but the idea is the same).

.006 is the correct valve clearance + or - .001

When adjusting the valves you need to slide the feeler gauge in and when you pull it out there will be a little resistance but it is not hard to pull it out. I have had it described to me as the amount of pressure would be similar to removing a sheet of paper from a closed book. Sort of a little bit of drag as you remove it but not needing a hard pull.

Measure your clearance (Please see above on how to do this - .006 is the correct intake valve clearance + or - .001, and .009 exhaust) and if it is too loose or to tight you need to loose the nut, and turn the slotted tappet. Remeasure and when you get it correct tight the nut down. The torque setting is 13 lbf.ft. DO NOT OVER TIGHTEN this nut as they can strip. Also once you get everything snugged up recheck your measurements as things can change a little as you get everything locked down. It does not take much of a turn of the tappet to change the clearance of the valve so always check and recheck everything.

Here is what it looks like when you are adjusting them

.006 is the correct intake valve clearance + or - .001

Mine was dead on .006/.009 so I didn't have to adjust mine - you may or may not have to so I staged this photo just for reference. Anyway, once everything is set correctly it is time to put the covers back on the valves, replace the inspection port cover, reattach the battery box, and put the plastic back in place along with the ECM.

That is really all there is to adjusting the valves. If things were easier to get to it would be a ten minute job - really the hardest thing is making sure you are at TDC, after that everything is accessible.

Last edited: