So one of the very first things that I installed on my 2019 1000-5 was a Seizmik bed extender X10D. I had ordered it before picking up the new Pioneer, and installed it immediately as we were leaving on a hunting trip 24 hours after picking up the rig.

Install per the instructions went fine. The bed extender worked great during the hunting trip. I gives much needed real estate when deployed, and folds up out of the way when not in use.

On a later ride with my wife, we heard a clatter from the back and discovered that one of the through bolts on the pivot bushings had vibrated loose. At this point the rig had maybe 320-350 miles on it. Seizmik specifies a threaded M8 bolt (30 mm long IIRC) and the design just wasn't adequate for the job. There were two problems. First, the bolt itself was not long enough to positively engage the nylon insert in the nut. That's why it vibrated loose. Second, running a smooth plastic bushing ID against a threaded bolt is pretty bush league. The threads had begun to wear/dig into the bushings.

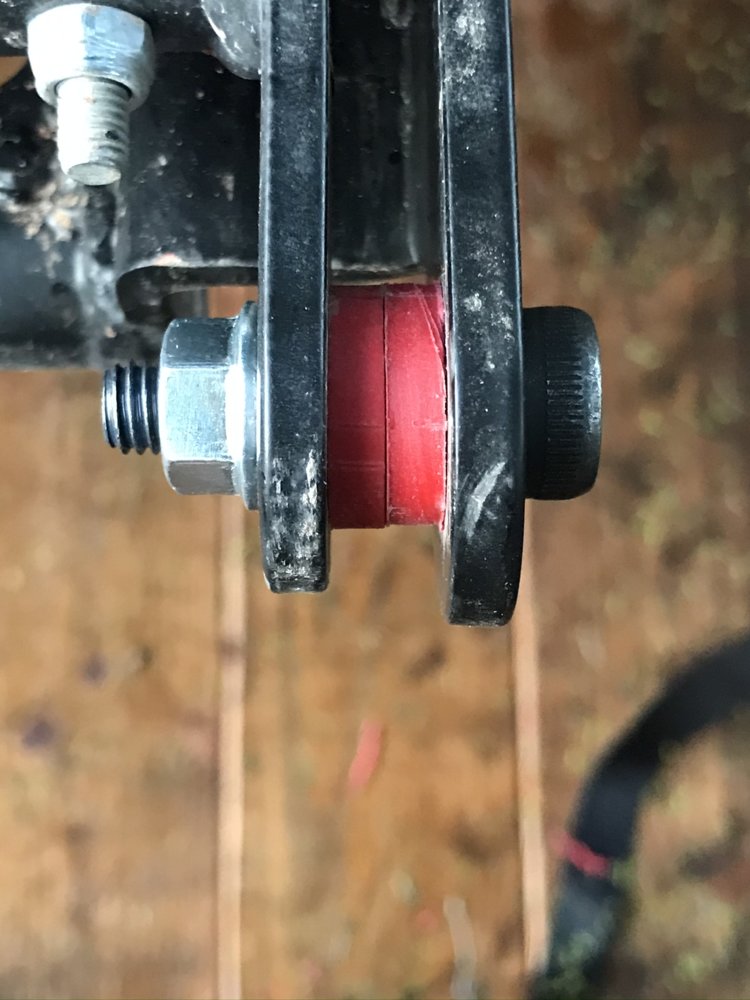

Sorry but I didn't get a picture of the thread damage to the bushings. I did take a photo of the opposite side bolt and nut as installed and you can see insufficient thread engagement into the nut's nylon insert. Because as designed it relies on the nylon insert to hold the nut in the correct position, you can't tighten it past a certain point without putting the bushing arrangement into a bind and preventing proper pivoting.

So I wandered down to my handy local ACE Hardware and found a proper shoulder bolt to solve the problem. Turns out they had one (and I failed to write down the callout it was something like M10 x 25). At any rate it has a 10 mm ground smooth OD and an 8mm threaded stub. You can see the original bolt/nylon inserted flange nut and the shoulder bolt/non inserted flange nut here.

Dug around in my drill set and found that 13/32 was about .010" larger than the 10 mm diameter on the new bolt.

Drilled the thread damaged bushings out and ran the new bolt in there. You can see that the new bolt's shoulder is just the right length to run the nut down hard against the shoulder (with blue Loctite) and now that dude pivots as smooth as a baby's behind and the nut isn't going to come off because it is hard against the shoulder and loctited.

After several subsequent trips it is all staying put and staying quiet. Only issue is surface rust has appeared on the non plated carbon steel bolt. I need to figure out a solution for that (maybe just keep it oiled). Here you can see that the new bolt head is larger than the original, but still clears the assembly when it pivots.

Overall the bed extender is a slick enhancement on the 1000-5 when you are using the back seats. Seismik got it 98% right: just goofed a bit on the pivot execution and it is easily addressed. I did talk to them on the phone about this so hopefully they will address the issue on future revisions of the design.

ETA: There are four pivot points where this problem could occur. So you will need four sets of shoulder bolts and flange nuts to do this job. There is no reason that you could not reuse the factory supplied flange nuts. Also, I used Blue Loctite to secure the nuts.

Install per the instructions went fine. The bed extender worked great during the hunting trip. I gives much needed real estate when deployed, and folds up out of the way when not in use.

On a later ride with my wife, we heard a clatter from the back and discovered that one of the through bolts on the pivot bushings had vibrated loose. At this point the rig had maybe 320-350 miles on it. Seizmik specifies a threaded M8 bolt (30 mm long IIRC) and the design just wasn't adequate for the job. There were two problems. First, the bolt itself was not long enough to positively engage the nylon insert in the nut. That's why it vibrated loose. Second, running a smooth plastic bushing ID against a threaded bolt is pretty bush league. The threads had begun to wear/dig into the bushings.

Sorry but I didn't get a picture of the thread damage to the bushings. I did take a photo of the opposite side bolt and nut as installed and you can see insufficient thread engagement into the nut's nylon insert. Because as designed it relies on the nylon insert to hold the nut in the correct position, you can't tighten it past a certain point without putting the bushing arrangement into a bind and preventing proper pivoting.

So I wandered down to my handy local ACE Hardware and found a proper shoulder bolt to solve the problem. Turns out they had one (and I failed to write down the callout it was something like M10 x 25). At any rate it has a 10 mm ground smooth OD and an 8mm threaded stub. You can see the original bolt/nylon inserted flange nut and the shoulder bolt/non inserted flange nut here.

Dug around in my drill set and found that 13/32 was about .010" larger than the 10 mm diameter on the new bolt.

Drilled the thread damaged bushings out and ran the new bolt in there. You can see that the new bolt's shoulder is just the right length to run the nut down hard against the shoulder (with blue Loctite) and now that dude pivots as smooth as a baby's behind and the nut isn't going to come off because it is hard against the shoulder and loctited.

After several subsequent trips it is all staying put and staying quiet. Only issue is surface rust has appeared on the non plated carbon steel bolt. I need to figure out a solution for that (maybe just keep it oiled). Here you can see that the new bolt head is larger than the original, but still clears the assembly when it pivots.

Overall the bed extender is a slick enhancement on the 1000-5 when you are using the back seats. Seismik got it 98% right: just goofed a bit on the pivot execution and it is easily addressed. I did talk to them on the phone about this so hopefully they will address the issue on future revisions of the design.

ETA: There are four pivot points where this problem could occur. So you will need four sets of shoulder bolts and flange nuts to do this job. There is no reason that you could not reuse the factory supplied flange nuts. Also, I used Blue Loctite to secure the nuts.

Last edited: