You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

L

Adam490

HFA Grand High Wizard

Lifetime Member

Supporting Member

@Plumber32 Plasti-Dipped his rig and it seems to be holding up pretty well. Far better than I ever thought it would. Maybe he's got some sort of magic Wisconsin plasti-dip or some secret plumber sauce....

Plumber32

Go ride!

Lifetime Member

Club Contributor

Yeah, the hardener/clearcoat spray makes a world of difference@Plumber32 Plasti-Dipped his rig and it seems to be holding up pretty well. Far better than I ever thought it would. Maybe he's got some sort of magic Wisconsin plasti-dip or some secret plumber sauce....

rustyneversleeps

Well-Known Member

Supporting Member

Is the hardener/clearcoat a separate can that you spray on top of the plastidip after its set? I was looking through your old posts, but couldn't find where you mentioned it before. ThanksYeah, the hardener/clearcoat spray makes a world of difference

L

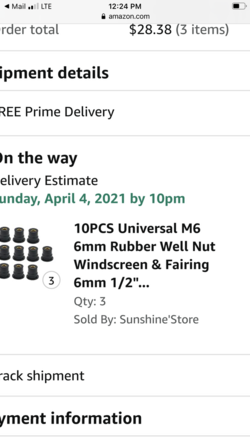

Those are the same that I ordered. They are the correct thread pitch. I measured with a caliper and think a 15/32 drill bit would be the best choice. A little tight but it would keep them from spinning when you screw the bolt in.

Thanks Logey

Sent from my iPhone using Tapatalk

advertisement

Checking back in now that I've done panel install. I didn't use any rubber grommets or anything. I just held the panel up to the door. Drilled out the holes and used the 8mm factory push pins to lock them on. Super easy.

View attachment 265241

Looks nice

Sent from my iPhone using Tapatalk

I'm still waiting on the back ordered front door panel though

Couple panels of mine are back ordered as well

Sent from my iPhone using Tapatalk

15/32” bit is definitely the way to go. Used a little soapy water to lube up the well nuts and used a small flat head driver to wedge them in and then turned and pressed them in until they snugged down flat. It’s a tight fit but it keeps the nuts from spinning when you bolt on the panels.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

15/32” bit is definitely the way to go. Used a little soapy water to lube up the well nuts and used a small flat head driver to wedge them in and then turned and pressed them in until they snugged down flat. It’s a tight fit but it keeps the nuts from spinning when you bolt on the panels.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

I have a base 16’ and mine just has black doors, with the red panel on the hood.I didn't realize that a person could buy one without the side panels. What did it cost for the panels?

Shiny! What was your reasoning for going with the nut and screw hardware rather than the push pins?15/32” bit is definitely the way to go. Used a little soapy water to lube up the well nuts and used a small flat head driver to wedge them in and then turned and pressed them in until they snugged down flat. It’s a tight fit but it keeps the nuts from spinning when you bolt on the panels.

View attachment 266205

View attachment 266206

View attachment 266207

View attachment 266208

View attachment 266209

Sent from my iPhone using Tapatalk

advertisement

Similar threads

- Replies

- 2

- Views

- 528

R

P1000

Rear/Mid Panel Window

- rubber_duck13

- Pioneer 1000 Accessories and Modifications

- Replies

- 3

- Views

- 600

R

D

P1000

Side mirror options

- dweber23tr

- Pioneer 1000 Accessories and Modifications

- Replies

- 2

- Views

- 635

E

P1000

Hard rear panel tips!

- elarson6772

- Pioneer 1000 Accessories and Modifications

- Replies

- 1

- Views

- 514

- Replies

- 2

- Views

- 155