Has anyone found LED light bar mounts that go over the visor on the OEM roof? I've found plenty that go across the hood but I want one higher. It seem like they'll need to mount to the bar and then go around the plastic. But I'd like to see what else is out there. ~ Thanks! ~

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

livefromthetree

It was a damn good ride. Seriously good.

Supporting Member

FWIW...I dont know but I have talked to two folks who had their light bars on the top and both said they moved them down because the lights attract too many bugs to your face vs. being up front. Seems logical...im going that route first.

Edit: Doggonit, I posted this in the wrong forum . . . should be in the P1000, and I can't figure out how to move it. Oh well.

I've just started my install of a 54" curved light bar on my '21 P1-5 SE. Decided to make my own brackets as I wanted the bottom of the bar even with the lower edge of the stock Honda roof (not blocking the windshield). I also wanted them sturdy, so used 1/4-20 rivet nuts in the upper doubler, rather than drilling through both sides, and using longer bolts, which would flex the doubler sides inward (unless a bushing spacer was inserted from the inside) - riv-nuts are easier. More pictures to follow as I get 'er done.

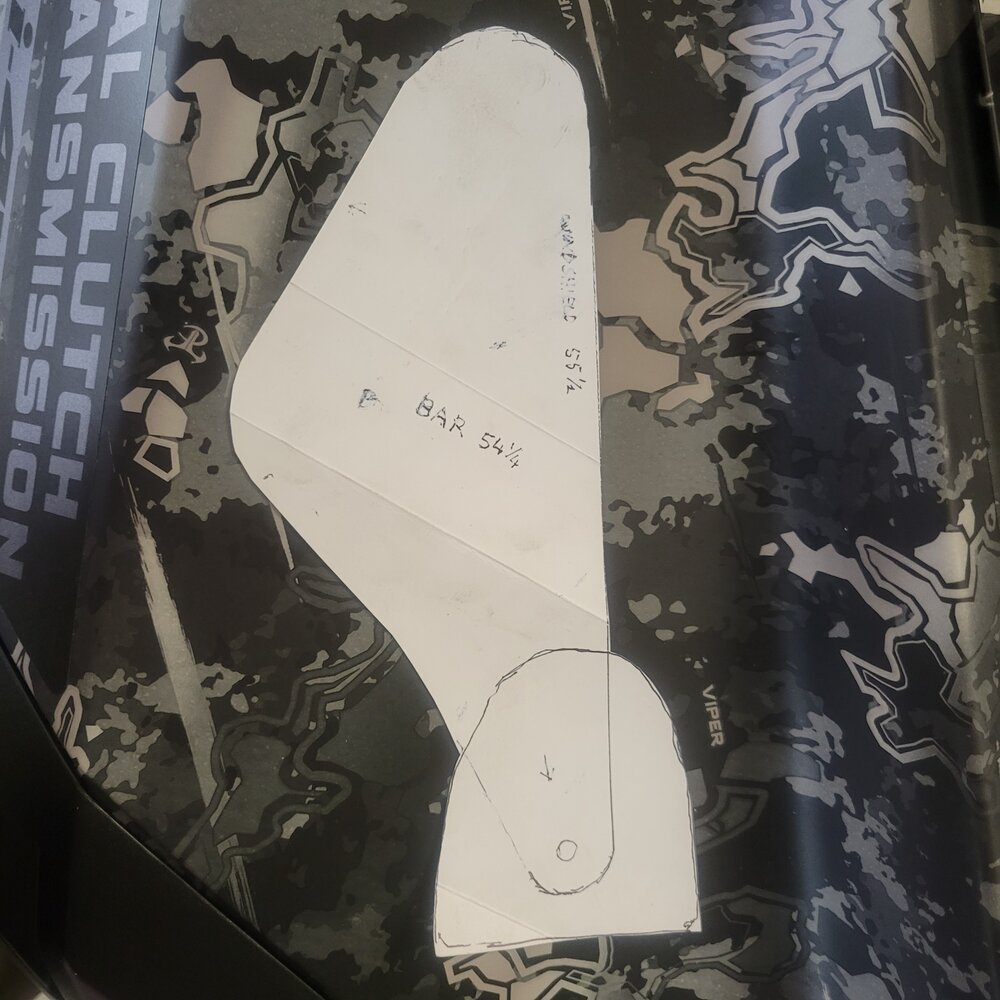

Started with a rough pattern including the shape of the light bar end. The brackets were made longer than this, the plan being to shorten the arm as much as possible to have minimal clearance between bar and roof edge while still being able to declinate the light as desired.

Do one riv-nut first so second one gets perfect spacing, using mount as drilling guide.

Riv-nuts are intentionally spaced further apart, than on some brackets I've seen, for added strength.

The end will be shortened more than shown here.

I've just started my install of a 54" curved light bar on my '21 P1-5 SE. Decided to make my own brackets as I wanted the bottom of the bar even with the lower edge of the stock Honda roof (not blocking the windshield). I also wanted them sturdy, so used 1/4-20 rivet nuts in the upper doubler, rather than drilling through both sides, and using longer bolts, which would flex the doubler sides inward (unless a bushing spacer was inserted from the inside) - riv-nuts are easier. More pictures to follow as I get 'er done.

Started with a rough pattern including the shape of the light bar end. The brackets were made longer than this, the plan being to shorten the arm as much as possible to have minimal clearance between bar and roof edge while still being able to declinate the light as desired.

Do one riv-nut first so second one gets perfect spacing, using mount as drilling guide.

Riv-nuts are intentionally spaced further apart, than on some brackets I've seen, for added strength.

The end will be shortened more than shown here.

Last edited:

trigger

Old Ironsides

Vendor

Lifetime Member

Supporting Member

Don't know exactly how you plan to finish this out but it's a known problem with roof mounted type that the bolts that go into the light bar have a tendency to work their way loose. Happened to me and found myself riding the trail with my light bar dangling from one bolt. With those extended brackets yours may be even more prone to it. FWIW @jak9922 came up with the threaded rod fix. It works and haven't had the problem for yrs now on a couple different light bars.

Thanks for the heads up. The light bar, unlike the with the mounting you show, will be below the roof line. (It would have been easy to use the supplied mounts to stick it up there higher!)

The light bar end caps are cast aluminum and threaded for the mounting bolt, looks robust enough to torque tightly, so unlikely they'll come loose - on the other hand, the threaded holes are not all that deep, so screw engagement length is less than half an inch. If they have a tendency to loosen, a bit of Loctite or Vibra-Tite thread locker should do the deed. Also, I'll be machining some black Delrin spacers for each side. The elasticity will give the bar end serrations more purchase - to help keep the bar from rotating, as well as to keep tension on the mounting threads (kinda like a lock washer would). The curved bar does cantilever some weight forward of the attach bolts, a straight bar wouldn't be so bad in that regard.

Searched but couldn't find anything on a "threaded rod fix", could you provide more info or a link please?

The light bar end caps are cast aluminum and threaded for the mounting bolt, looks robust enough to torque tightly, so unlikely they'll come loose - on the other hand, the threaded holes are not all that deep, so screw engagement length is less than half an inch. If they have a tendency to loosen, a bit of Loctite or Vibra-Tite thread locker should do the deed. Also, I'll be machining some black Delrin spacers for each side. The elasticity will give the bar end serrations more purchase - to help keep the bar from rotating, as well as to keep tension on the mounting threads (kinda like a lock washer would). The curved bar does cantilever some weight forward of the attach bolts, a straight bar wouldn't be so bad in that regard.

Searched but couldn't find anything on a "threaded rod fix", could you provide more info or a link please?

C

Thanks for the heads up. The light bar, unlike the with the mounting you show, will be below the roof line. (It would have been easy to use the supplied mounts to stick it up there higher!)

The light bar end caps are cast aluminum and threaded for the mounting bolt, looks robust enough to torque tightly, so unlikely they'll come loose - on the other hand, the threaded holes are not all that deep, so screw engagement length is less than half an inch. If they have a tendency to loosen, a bit of Loctite or Vibra-Tite thread locker should do the deed. Also, I'll be machining some black Delrin spacers for each side. The elasticity will give the bar end serrations more purchase - to help keep the bar from rotating, as well as to keep tension on the mounting threads (kinda like a lock washer would). The curved bar does cantilever some weight forward of the attach bolts, a straight bar wouldn't be so bad in that regard.

Searched but couldn't find anything on a "threaded rod fix", could you provide more info or a link please?

Did you ever find a solution?Thanks for the heads up. The light bar, unlike the with the mounting you show, will be below the roof line. (It would have been easy to use the supplied mounts to stick it up there higher!)

The light bar end caps are cast aluminum and threaded for the mounting bolt, looks robust enough to torque tightly, so unlikely they'll come loose - on the other hand, the threaded holes are not all that deep, so screw engagement length is less than half an inch. If they have a tendency to loosen, a bit of Loctite or Vibra-Tite thread locker should do the deed. Also, I'll be machining some black Delrin spacers for each side. The elasticity will give the bar end serrations more purchase - to help keep the bar from rotating, as well as to keep tension on the mounting threads (kinda like a lock washer would). The curved bar does cantilever some weight forward of the attach bolts, a straight bar wouldn't be so bad in that regard.

Searched but couldn't find anything on a "threaded rod fix", could you provide more info or a link please?

My dealer mounted mine light bar to the roof and it’s not right. It shakes from the edge of plastic roof not being stiff enough. If moved up it will be above roof and to easy to get knocked off.

Someone should make a Mount for the roll bar pipe under the roof and have the mounting bracket come out from under the roof and curve up to Mount the light bar.

I guess I will have to fabricate something

Rock On

Tom

Did you ever find a solution?

My dealer mounted mine light bar to the roof and it’s not right. It shakes from the edge of plastic roof not being stiff enough. If moved up it will be above roof and to easy to get knocked off.

Someone should make a Mount for the roll bar pipe under the roof and have the mounting bracket come out from under the roof and curve up to Mount the light bar.

I guess I will have to fabricate something

Rock On

Tom

Yes, see earlier post #5 is this thread. No, I wouldn't accept a light bar mounted on top of the roof for a number of reasons. I think part of the reason they don't come out between the windshield and roll bar, at least on the horizontal part, is due to the way the windshield mounts are designed. It's a pretty "busy" area, that and the roll bar gusset would mean a mount clamped to the roll bar would, of necessity, require a long and probably curved mounting arm. To be rigid enough to not have the light bouncing up and down, requires the mount plate be vertical, so it would be difficult to design something that'll work and have it involve a horizontal "strap" of any sort - - my light bar is fairly heavy. For a roof mount, I think the one I designed is optimal. It ended up a bit shorter than the part shown in #5 above:

Last edited:

Yes, see earlier post #5 is this thread. No, I wouldn't accept a light bar mounted on top of the roof for a number of reasons. I think part of the reason they don't come out between the windshield and roll bar, at least on the horizontal part, is due to the way the windshield mounts are designed. It's a pretty "busy" area, that and the roll bar gusset would mean a mount clamped to the roll bar would, of necessity, require a long and probably curved mounting arm. To be rigid enough to not have the light bouncing up and down, requires the mount plate be vertical, so it would be difficult to design something that'll work and have it involve a horizontal "strap" of any sort - - my light bar is fairly heavy. For a roof mount, I think the one I designed is optimal. It ended up a bit shorter than the part shown in #5 above:

View attachment 309906

View attachment 309910

I like your setup! Any updates on the performance? Do you get bugs around your head (described earlier)? Or glare? How's it working in snow or rain?

Also how did you mount those red shackles on the front?

Good looking ride!

advertisement

Haven't noticed any bug attraction, no glare at all, have not tested in snow or rain, however, I'm sure fog would result in an unacceptable amount of glare, as the light bar is very bright.

Shackles are currently bolted through a doubler on the backside. I thought about welding them, but got lazy as I didn't want to paint. If there's a problem, I'll bevel the mounting edges and weld them in the future.

Shackles are currently bolted through a doubler on the backside. I thought about welding them, but got lazy as I didn't want to paint. If there's a problem, I'll bevel the mounting edges and weld them in the future.

Similar threads

C

- Replies

- 1

- Views

- 55

F

- Replies

- 3

- Views

- 830

K

- Replies

- 2

- Views

- 636