If these bolts are indeed metric (which I believe they are). The torque specs are probably listed in Newtons. 9 newtons is 2 lbs.

Does they manual actually say "9 ft-lbs"? If so, that may be the misprint.

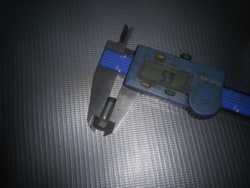

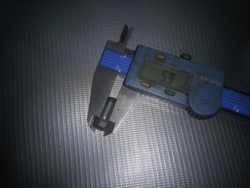

They are metric - M5 (with an 8mm hex head). I can't speculate on what Honda may have intended to say or if it is a misprint, all I can do is give you this quote of the exact words printed in the Honda owners manual that was delivered with my vehicle.

And I quote from page 114, paragraph 12. of the Honda P500 Pioneer owners manual:

"12. Reinstall the oil filter cover, making sure the bolts are tightened to the specified torque: 9 lbf-ft (12 N-m, 1.2 kgf-m)"

Note that they even put the spec. in bold type!

I don't know how this can be misinterpreted, it's pretty darn specific.....maybe an error of intention, but there nevertheless for all owners to follow!

jak9922, If I had turned the other two after the first one broke, I'm sure they would have likewise snapped. When I went to remove the two, it took absolutely no force to "break them loose", being no pressure against the bolt head whatsoever. They had already yielded and were at the breaking point.