G

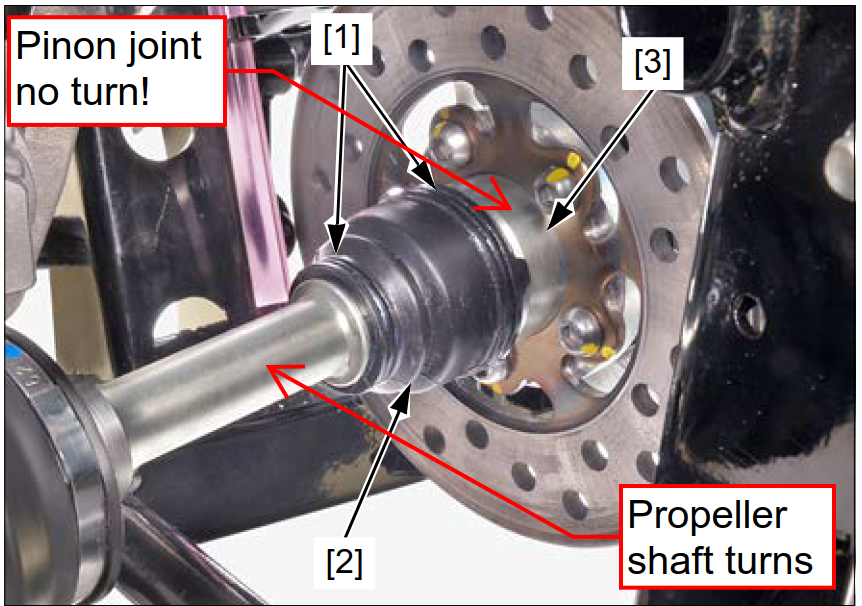

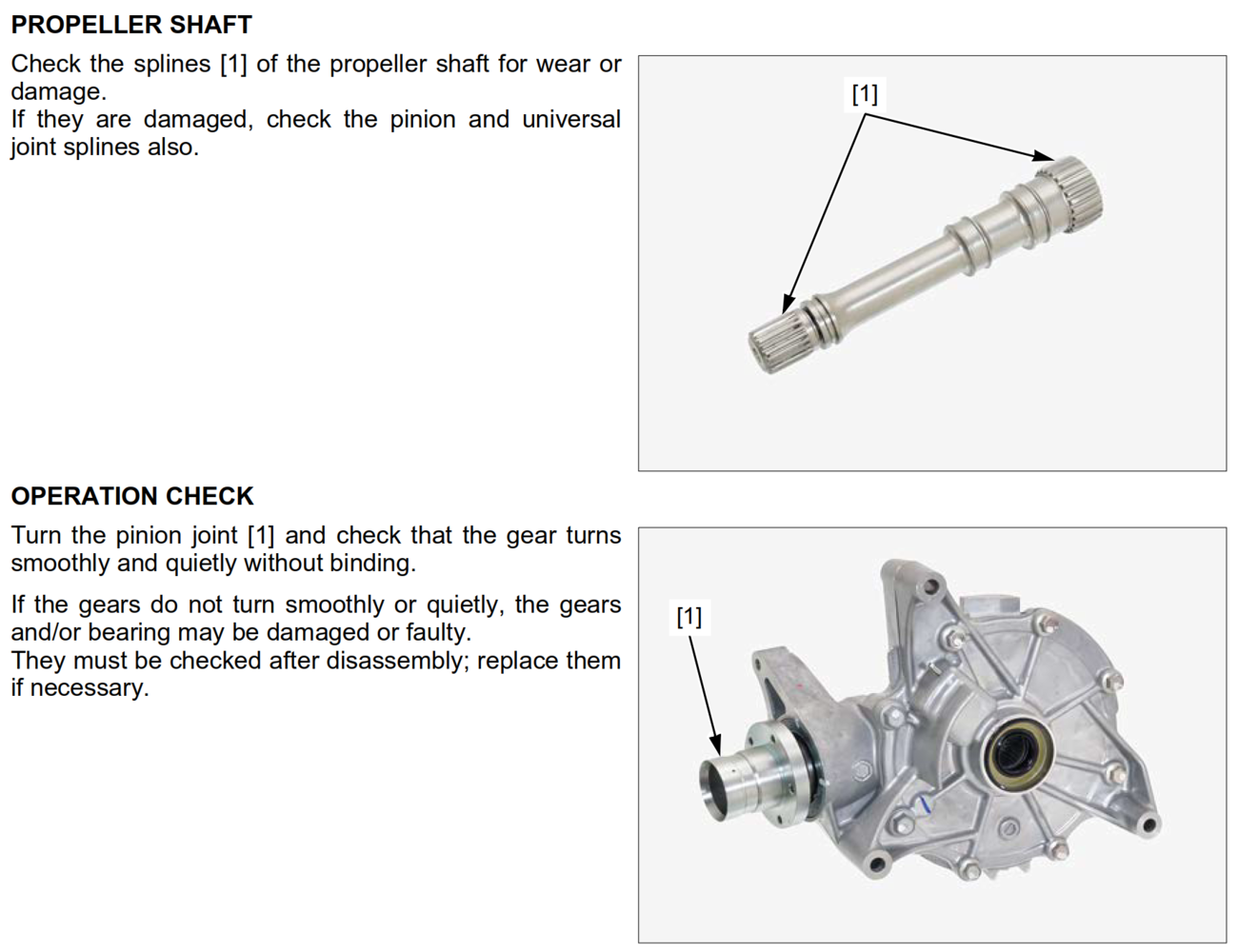

Our P520 has had a disconcerting rattle/clunking sounds at certain speeds coming from the rear final drive area since new. We never could find anything wrong looking/feeling/listening, but did not take anything apart. My kids walked home yesterday, and we definitely have a failed pinion joint. Drive shaft runs right up to the hub rear brake is mounted on, but that hub and brake disc don't move at all. In 2 wheel drive, there's no effort to move, and in 4x4 we get a 1 wheel spin up front (both until one slips). One wheel drive doesn't get far in winter!

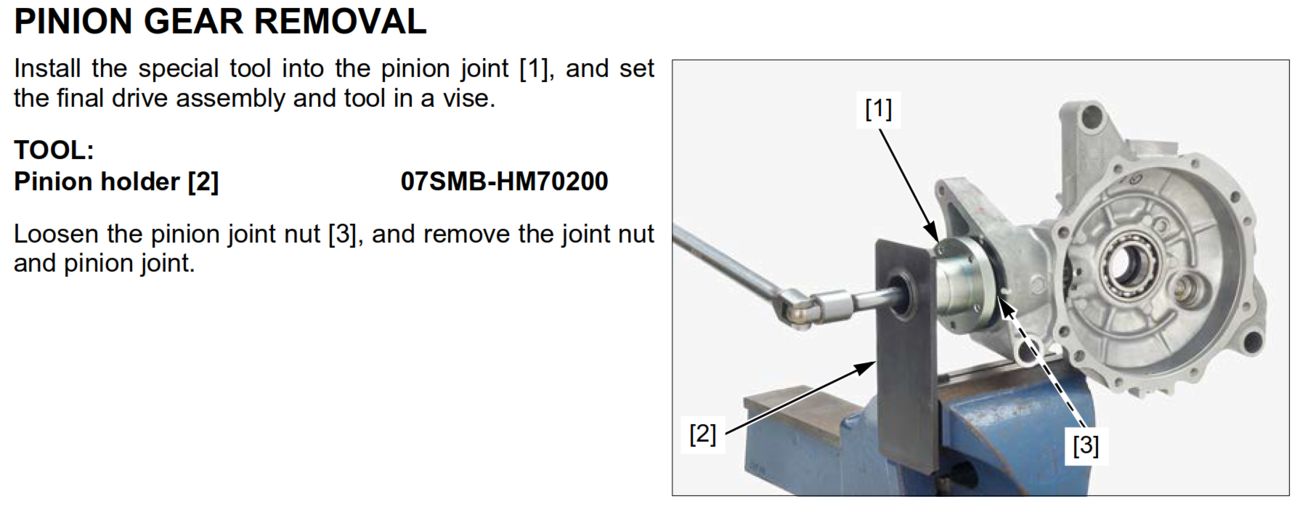

Here shop manual shows what it'll look like with boot off (if nothing were mashed):

I found a couple threads where others had this failure:

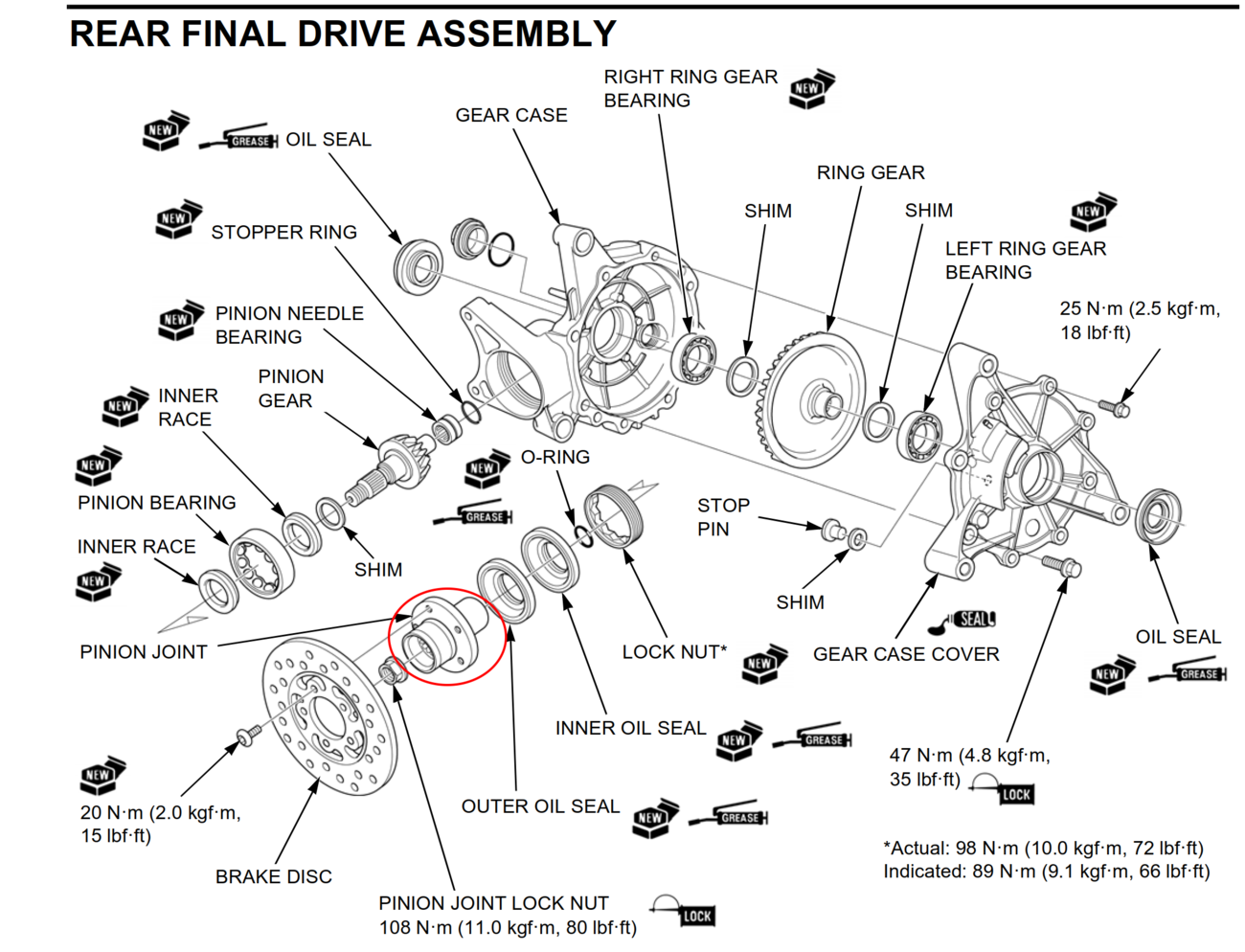

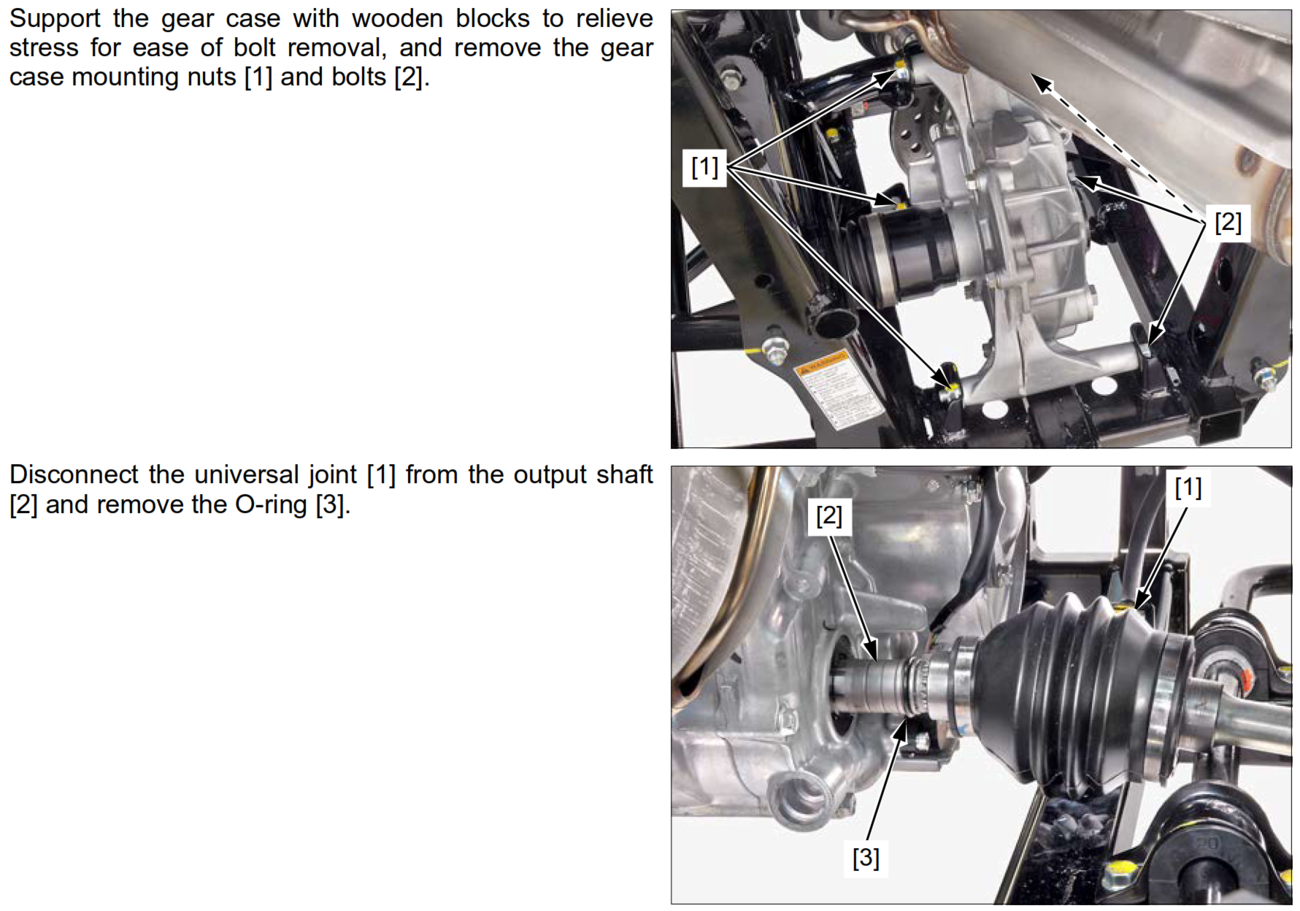

It looks like it may be possible to remove rear final drive mounting bolts and shift things enough to remove u-joint from transmission output connection and then pull it out of pinion joint.

I'm not sure if we can do this in place, or if we'll have to remove the rear drive shafts from final drive and take it right out.

My shop is the great outdoors which is cold & snowy at this time of year in the north (similar latitude as Wrangle, AK, but further inland where it tends to be chillier). Dealers are 10 h drive away (in either direction). Any tips from anyone who's replaced one of these?

Here shop manual shows what it'll look like with boot off (if nothing were mashed):

I found a couple threads where others had this failure:

- Rear Propeller Shaft and Pinion Joint Connection GONE BAD

- Rear Final Gear box internal clunking noise. - This one really resonates with our experience of hearing noise coming from the back, followed (a couple years later in our case, though noise got much more noticeable very recently) with pinion joint failure.

It looks like it may be possible to remove rear final drive mounting bolts and shift things enough to remove u-joint from transmission output connection and then pull it out of pinion joint.

I'm not sure if we can do this in place, or if we'll have to remove the rear drive shafts from final drive and take it right out.

My shop is the great outdoors which is cold & snowy at this time of year in the north (similar latitude as Wrangle, AK, but further inland where it tends to be chillier). Dealers are 10 h drive away (in either direction). Any tips from anyone who's replaced one of these?