Tflynn

Not a liberal

Lifetime Member

Club Contributor

I adjusted my valves the other day and found it is really quite simple to do on the 700. I have never adjusted valves on anything before so I just wanted to kind of add to what the service manual says and add a few pictures. The service manual is pretty brief on this topic, which made me put off doing it! But it's really not bad. Not sure I'll call this a "How To" because I don't have many pictures at the end. So if you have some please add them!

Tools needed-

10mm wrench

Phillips head screwdriver

Flathead screwdriver

17mm socket

24mm (I think) socket

8 mm socket

6mm Allen wrench

First you must gain access by raising the bed then removing the seat and the two panels under the driver seat. You'll have to remove a bunch of plastic rivets. Don't worry, by the 3rd or 4th one you'll be good at it! And on the bigger panel there are 3 Phillips head screws as well.

First this little panel comes off

Then this larger one-

I also removed the seat back for more room but that's not necessary to do. Ok now we can see the engine!

I should say, this is a great time to replace your spark plug as you have great access to it with these panels removed.

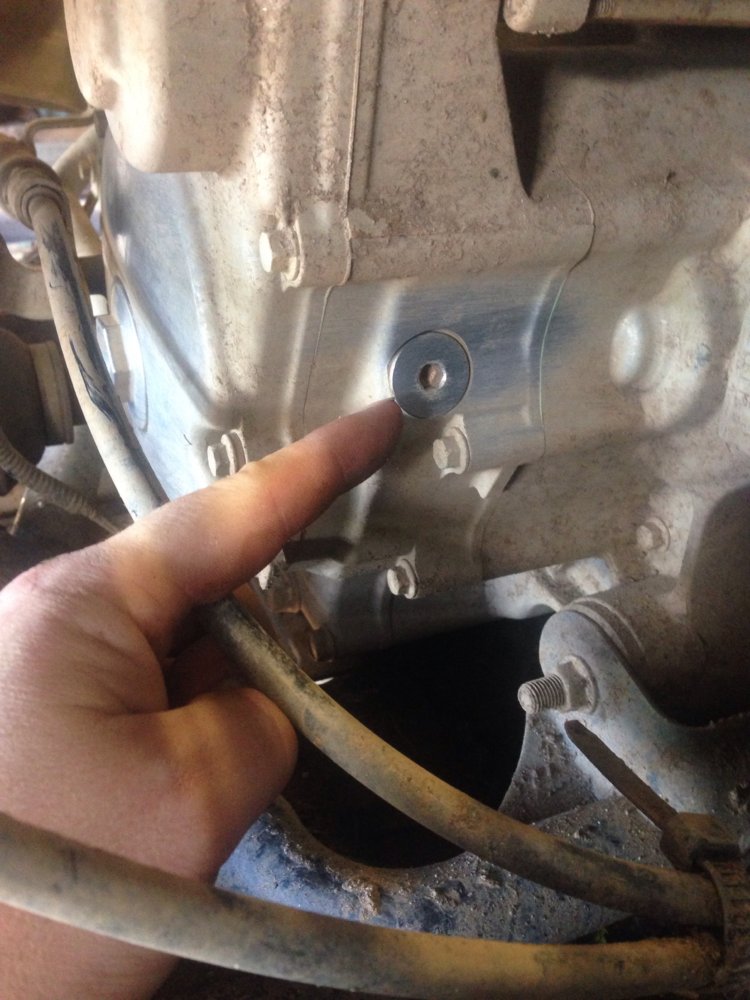

So next you have to get the engine to top dead center on the compression stroke. If you look at the side of the engine in front of the passenger side rear tire (got that?) you should see this-

Remove that plug with your 6mm Allen wrench.

And remove this cap (the only bolt head somewhat clean in the picture) I think it is a 24mm.

With the 24mm cap removed, you can insert your 17mm into the hole (you probably need an extension) and turn the fly wheel. The manual says to only turn it clock wise. So as you slowly turn it, you have to look in the hole where you removed the plug with the 6mm Allen. You will see the flywheel rotating through this hole. You are looking for a sideways T with a line under it stamped in the flywheel.

I apologize for the photo quality, this was a very difficult picture to get! But on the right hand side of the hole you can see the sideways T and the line under it is hidden by the glare from the flash. You want to line up the line with the tab on the case that is barely visible in the photo.

Note- there is also a sideways F with a line under it on the flywheel! Don't get them confused, and while turning the flywheel when you see the F, the T is coming RIGHT behind it.

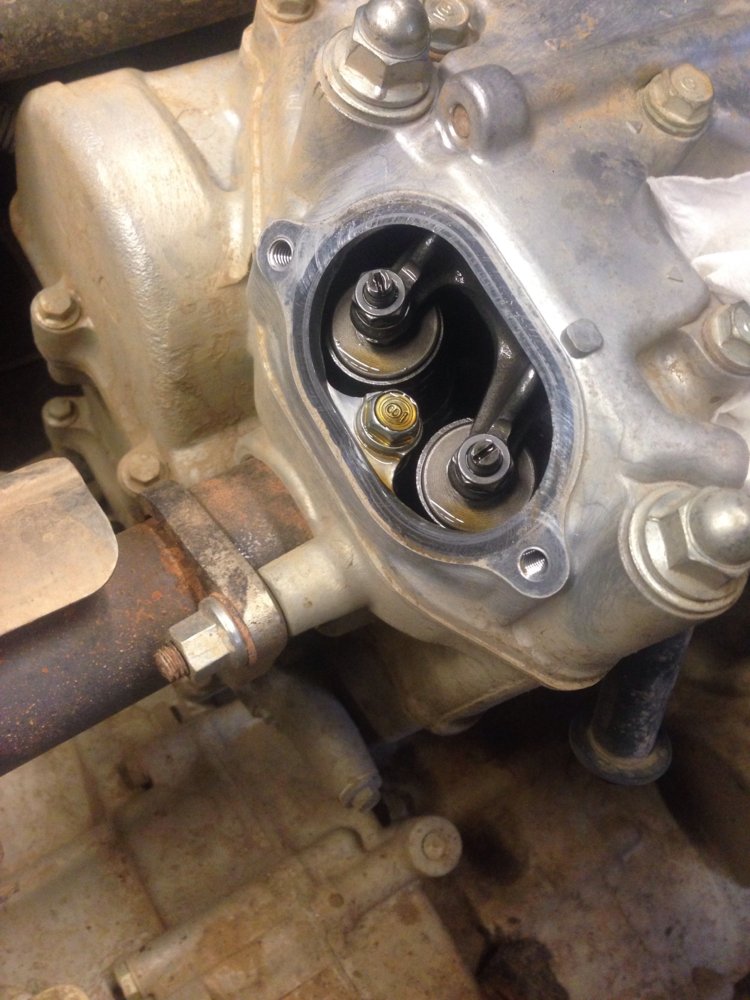

So with the piston at TDC you must verify its on the compression stroke. This is easily done by removing the valve covers and giving the rocker arms a wiggle. If there's play, then you are on the compression stroke (good!). If there's no play in the rocker arm, rotate the flywheel around one complete revolution and then you'll be on the compression stroke. Here you can see the rocker arms (the dark arms going to the nut in the center of the valve).

The above photo shows both exhaust valves (valves on the side where the exhaust pipe goes out). These are supposed to be adjusted to .013 inches with a feeler gauge. On the opposite side of the cylinder head are the two intake valves. These are supposed to be at .006 inches.

If your feeler gauge fits between the rocker arm and valve easily and can move around with ease, then your valves are too loose.

Put a 10mm wrench on the nut in the center of the valve (on the end of the rocker arm) and a flat head screw driver on the adjustment screw that the nut is on. Loosen the nut, then you can turn the adjustment screw. Get it down to where you are able to feel some drag on the feeler gauge, probably won't take more than a 1/4-1/2 a turn. When you think you're good, tighten the nut (while holding the adjustment screw) then check again with the feeler gauge. If everything is good, then oil the O-ring on the valve covers and put them back on. DONT FORGET your inspection hole and flywheel hole covers! Once all covers are reinstalled, I like to start the engine to make sure everything sounds good. If it does, then put the plastic panels back on and enjoy your smooth running engine!

Tools needed-

10mm wrench

Phillips head screwdriver

Flathead screwdriver

17mm socket

24mm (I think) socket

8 mm socket

6mm Allen wrench

First you must gain access by raising the bed then removing the seat and the two panels under the driver seat. You'll have to remove a bunch of plastic rivets. Don't worry, by the 3rd or 4th one you'll be good at it! And on the bigger panel there are 3 Phillips head screws as well.

First this little panel comes off

Then this larger one-

I also removed the seat back for more room but that's not necessary to do. Ok now we can see the engine!

I should say, this is a great time to replace your spark plug as you have great access to it with these panels removed.

So next you have to get the engine to top dead center on the compression stroke. If you look at the side of the engine in front of the passenger side rear tire (got that?) you should see this-

Remove that plug with your 6mm Allen wrench.

And remove this cap (the only bolt head somewhat clean in the picture) I think it is a 24mm.

With the 24mm cap removed, you can insert your 17mm into the hole (you probably need an extension) and turn the fly wheel. The manual says to only turn it clock wise. So as you slowly turn it, you have to look in the hole where you removed the plug with the 6mm Allen. You will see the flywheel rotating through this hole. You are looking for a sideways T with a line under it stamped in the flywheel.

I apologize for the photo quality, this was a very difficult picture to get! But on the right hand side of the hole you can see the sideways T and the line under it is hidden by the glare from the flash. You want to line up the line with the tab on the case that is barely visible in the photo.

Note- there is also a sideways F with a line under it on the flywheel! Don't get them confused, and while turning the flywheel when you see the F, the T is coming RIGHT behind it.

So with the piston at TDC you must verify its on the compression stroke. This is easily done by removing the valve covers and giving the rocker arms a wiggle. If there's play, then you are on the compression stroke (good!). If there's no play in the rocker arm, rotate the flywheel around one complete revolution and then you'll be on the compression stroke. Here you can see the rocker arms (the dark arms going to the nut in the center of the valve).

The above photo shows both exhaust valves (valves on the side where the exhaust pipe goes out). These are supposed to be adjusted to .013 inches with a feeler gauge. On the opposite side of the cylinder head are the two intake valves. These are supposed to be at .006 inches.

If your feeler gauge fits between the rocker arm and valve easily and can move around with ease, then your valves are too loose.

Put a 10mm wrench on the nut in the center of the valve (on the end of the rocker arm) and a flat head screw driver on the adjustment screw that the nut is on. Loosen the nut, then you can turn the adjustment screw. Get it down to where you are able to feel some drag on the feeler gauge, probably won't take more than a 1/4-1/2 a turn. When you think you're good, tighten the nut (while holding the adjustment screw) then check again with the feeler gauge. If everything is good, then oil the O-ring on the valve covers and put them back on. DONT FORGET your inspection hole and flywheel hole covers! Once all covers are reinstalled, I like to start the engine to make sure everything sounds good. If it does, then put the plastic panels back on and enjoy your smooth running engine!