You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ohanacreek

My EcoBoost has I4WD

Moderator

Lifetime Member

I'm new to the board. Can someone advise if these wheels would work on the p500.

7 12x7 4/110mm with +10mm offset rims.

Thank you for your time

Sent from my SM-G935V using Tapatalk

Correct lug pattern, 10mm is 4/3 offset. Not sure what factory offset is.

I'm new to the board. Can someone advise if these wheels would work on the p500.

7 12x7 4/110mm with +10mm offset rims.

Thank you for your time

Sent from my SM-G935V using Tapatalk

Got a link? I have ITP wheels and dont recall them ever describing the offset in MM.

It's a Craigslist add for ITP series C type 7 polished. Not sure if that helps. Thanks!Got a link? I have ITP wheels and dont recall them ever describing the offset in MM.

Sent from my SM-G935V using Tapatalk

UpdateIt's a Craigslist add for ITP series C type 7 polished. Not sure if that helps. Thanks!

Sent from my SM-G935V using Tapatalk

It looks like the back says +10, these are 7" with 2.5" offset he said they came off a Rincon. Does that help?

Sent from my SM-G935V using Tapatalk

Sorry, I got nothin. I guess you can measure from the bead to the rim surface on both sides and see what they are..5+2 or 4+3 I think were the option if I remember.

G

Looks like a 3+5? Would you agree? Would these be a good choice with stock wheels for now until I upgrade? I can get a good price on them.

Sent from my SM-G935V using Tapatalk

advertisement

rocmar

Where Eagles & Angels....Dare to Fly...

Lifetime Member

Me either...10mm....?Got a link? I have ITP wheels and dont recall them ever describing the offset in MM.

5+2.......4+3......is wat

I've went by...

I'm not a tire guy...

Might be a new...way of

description. ...

I'm all ears...if someone wants

....or can explain

...Learning new tech....

lee

Village Idiot

Lifetime Member

Club Contributor

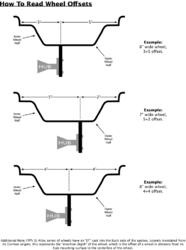

In the auto wheel industry 'offset' is the standard method to spec out a wheel.

In the after market for cars and trucks they often use backset or back spacing.

The whole 5+2 etc thing is a go cart / ATC thing.

Offset is the measurement from the center of the tire to the mounting face of the hub.

If the styling face of the wheel is thicker than the back side it dosent have any impact, the center of the tire is set from the face the tire bead sets up against.

The difficulty with this method is it can be hard to measure the actual wheel to find the tire center which is an imaginary plane in space - you can not hook a tape measure on it.

Back spacing is the distance from the hub mounting face to the inside bead face of the tire.

It is a little easyer to measure and with some simple math you can calculate it in your head (you have to account for the thickness of the inner bead seat area).

The problem is people take short cuts and simply measure from the back edge of the wheel and this gives an inaccurate definition of the part.

The 5+2 nomenclature is a short cut that does not tell the whole.story.

it came about from making wheels from 2 bell shaped halves.

The 1st number is the depth of the outer bell, the 2nd number the depth of the inner bell.

This is an easy to make way to do wheels.

The problem is without the thickness of the material you do not know where the hub mounting face is.

So, a 10mm offset isngoingnto have the hub mounting face 10mm closer to the front as measured from the tire center line.

This will be close to a 3+4 (with out knowing all the details).

In the after market for cars and trucks they often use backset or back spacing.

The whole 5+2 etc thing is a go cart / ATC thing.

Offset is the measurement from the center of the tire to the mounting face of the hub.

If the styling face of the wheel is thicker than the back side it dosent have any impact, the center of the tire is set from the face the tire bead sets up against.

The difficulty with this method is it can be hard to measure the actual wheel to find the tire center which is an imaginary plane in space - you can not hook a tape measure on it.

Back spacing is the distance from the hub mounting face to the inside bead face of the tire.

It is a little easyer to measure and with some simple math you can calculate it in your head (you have to account for the thickness of the inner bead seat area).

The problem is people take short cuts and simply measure from the back edge of the wheel and this gives an inaccurate definition of the part.

The 5+2 nomenclature is a short cut that does not tell the whole.story.

it came about from making wheels from 2 bell shaped halves.

The 1st number is the depth of the outer bell, the 2nd number the depth of the inner bell.

This is an easy to make way to do wheels.

The problem is without the thickness of the material you do not know where the hub mounting face is.

So, a 10mm offset isngoingnto have the hub mounting face 10mm closer to the front as measured from the tire center line.

This will be close to a 3+4 (with out knowing all the details).

T

rocmar

Where Eagles & Angels....Dare to Fly...

Lifetime Member

In the auto wheel industry 'offset' is the standard method to spec out a wheel.

In the after market for cars and trucks they often use backset or back spacing.

The whole 5+2 etc thing is a go cart / ATC thing.

Offset is the measurement from the center of the tire to the mounting face of the hub.

If the styling face of the wheel is thicker than the back side it dosent have any impact, the center of the tire is set from the face the tire bead sets up against.

The difficulty with this method is it can be hard to measure the actual wheel to find the tire center which is an imaginary plane in space - you can not hook a tape measure on it.

Back spacing is the distance from the hub mounting face to the inside bead face of the tire.

It is a little easyer to measure and with some simple math you can calculate it in your head (you have to account for the thickness of the inner bead seat area).

The problem is people take short cuts and simply measure from the back edge of the wheel and this gives an inaccurate definition of the part.

The 5+2 nomenclature is a short cut that does not tell the whole.story.

it came about from making wheels from 2 bell shaped halves.

The 1st number is the depth of the outer bell, the 2nd number the depth of the inner bell.

This is an easy to make way to do wheels.

The problem is without the thickness of the material you do not know where the hub mounting face is.

So, a 10mm offset isngoingnto have the hub mounting face 10mm closer to the front as measured from the tire center line.

This will be close to a 3+4 (with out knowing all the details).

Looked through wheel sales

...no one using...mm..

to explain wheels....using offset

5+2....4+3..

...ect..

Liked your post

think..Chooglin got a

..offset video..on here

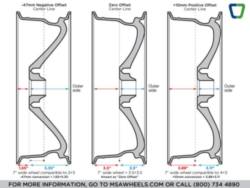

So after much research a +10mm offset is a 4+3. See below. That being said is this a good choice for our P5's?Looked through wheel sales

...no one using...mm..

to explain wheels....using offset

5+2....4+3..

...ect..

Liked your post

think..Chooglin got a

..offset video..on here

Sent from my SM-G935V using Tapatalk

rocmar

Where Eagles & Angels....Dare to Fly...

Lifetime Member

Alot of riders...going with 4+3So after much research a +10mm offset is a 4+3. See below. That being said is this a good choice for our P5's?

View attachment 72500

Sent from my SM-G935V using Tapatalk

.....I'm using 5+2.....with 2"spacers...

im.....58"....wide in rear

57"+.....in front...

very

stable....

Similar threads

A

- Replies

- 2

- Views

- 1K