You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

i just lightly tighten with 1/4 drive wrench, all you need is snug, if you crank it down too much you will flaten the oring or warp the cover and make it leak

J

Thanks! Will try likely tonight. Since this cap isn't holding much oil pressure (if any at all), snug will be fine!i just lightly tighten with 1/4 drive wrench, all you need is snug, if you crank it down too much you will flaten the oring or warp the cover and make it leak

DG Rider

Member: Triple Clutch Club

Lifetime Member

Tight. Like @jwfirebird said.What torque did you use on the valve caps (8mm bolts)? I think they should be 10-12 N.m but the manual doesn't specify this.

You start using Honda torque specs and you'll have broken bolts.

J

Oh boy... That is not reassuring! You would think the safe route is to follow the manual!Tight. Like @jwfirebird said.

You start using Honda torque specs and you'll have broken bolts.

J

Thank you guys for all this great info. I just completed my first valve clearance check and I am glad I did it. All four valves were out of spec (too loose by .002 on the intake and 0.004(!) on the exhaust, couldn't believe it so I checked and rechecked, turned the CS one more turn and re-re-checked). Brought them all to spec and the engine runs smooth. Can't wait to test drive it.

Smitty335

Well-Known Member

Lifetime Member

Supporting Member

I use the wrist torque wrench and anti seize.What torque did you use on the valve caps (8mm bolts)? I think they should be 10-12 N.m but the manual doesn't specify this.

William

If you ain’t first, you’re last...

Lifetime Member

Thanks... You really poked at my OCD and I just had to remove and antiseize the bolts... I did the exhaust tip bolts the day I got it...I use the wrist torque wrench and anti seize.

Welcome aboard from Northeast Texas! Keep reading and you'll find more interesting facts.Awesome guide... my dealer never said a word about this yesterday when i bought my P-700-4. Hadnt looked in the manual yet either. He went over the break in period and oil change but that was it. Glad i stumbled across this.

advertisement

Thanks! I am from Southeast Texas. I sure have been, lots of good info on here.Welcome aboard from Northeast Texas! Keep reading and you'll find more interesting facts.

take a look at your front wheels alot of people have found the toe way off too, mine was a few inches instead of the quarter to an eight it should be. super easy though on these just back the nut off the adjuster off the tie rod, just threads in or out

Russ989

Land of the free because of the Brave! 🇺🇸

Lifetime Member

Supporting Member

Club Contributor

I just adjusted mine at 672 miles, the exhaust valves were on the money but the intake valves were loose. I used a torque wrench and a 10mm crows foot to torque mine down.

Last edited:

DG Rider

Member: Triple Clutch Club

Lifetime Member

What torque did you use? Hopefully you compensated for the crows foot, which throws the torque reading off.I just adjusted mine at 672 miles, the exhaust valves were on the money but the intake valves were loose. I used a torque wrench and a 10mm crows foot to torque mine down.

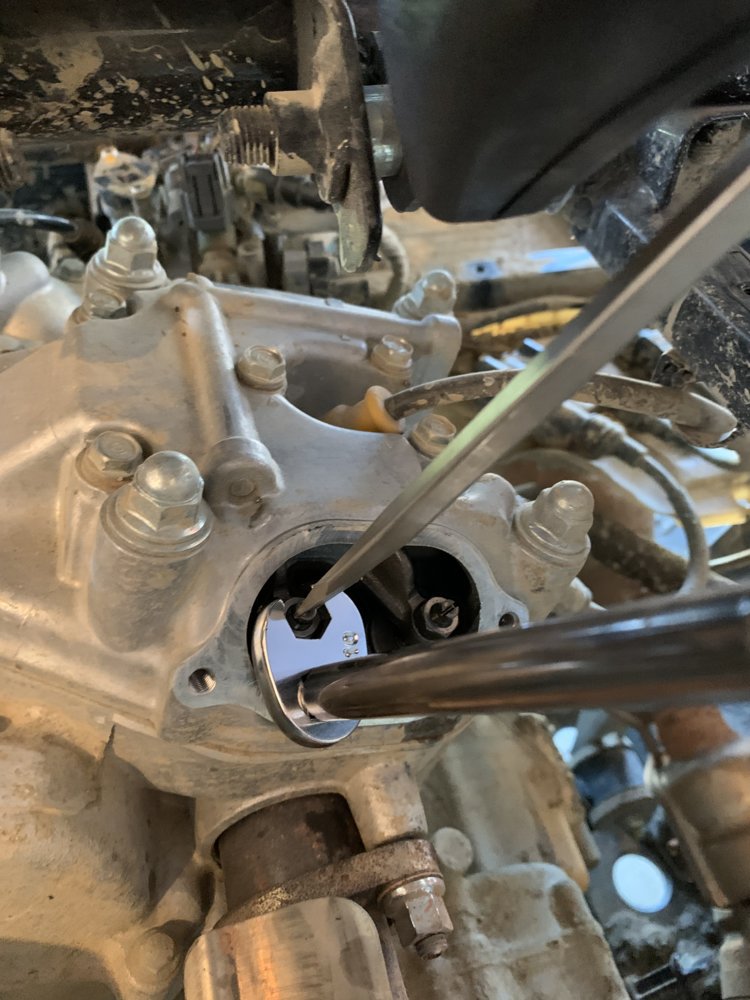

View attachment 157262

View attachment 157267

Russ989

Land of the free because of the Brave! 🇺🇸

Lifetime Member

Supporting Member

Club Contributor

I backed it to 11ft pounds. I knew there would be some difference by using the crows foot but didn’t want the chance of the tappet moving while torquing with a socket. The research I did suggested that as long as the crows foot is at 90 degrees there would only be minimal discrepancy. I also checked the lock nut with a wrench afterwards.What torque did you use? Hopefully you compensated for the crows foot, which throws the torque reading off.

I just finished checking the clearance of the intake and exhaust valves.

The intake clearance on the lifters were good at 0.006" but the exhaust was about 0.009".

After adjusting the exhaust to 0.013" and then starting the engine (after bolting all covers back on) I now have slight ticking noise coming from the exhaust.

I made sure it was little bit of grab as the 0.013" gauge slid through the gap.

I don't know if I should go back and check it again.

The intake clearance on the lifters were good at 0.006" but the exhaust was about 0.009".

After adjusting the exhaust to 0.013" and then starting the engine (after bolting all covers back on) I now have slight ticking noise coming from the exhaust.

I made sure it was little bit of grab as the 0.013" gauge slid through the gap.

I don't know if I should go back and check it again.

DG Rider

Member: Triple Clutch Club

Lifetime Member

I would say recheck it just for peace of mind, but there will be a light tapping when properly adjusted. Just make sure it's at room temp when you recheck.I just finished checking the clearance of the intake and exhaust valves.

The intake clearance on the lifters were good at 0.006" but the exhaust was about 0.009".

After adjusting the exhaust to 0.013" and then starting the engine (after bolting all covers back on) I now have slight ticking noise coming from the exhaust.

I made sure it was little bit of grab as the 0.013" gauge slid through the gap.

I don't know if I should go back and check it again.

Russ989

Land of the free because of the Brave! 🇺🇸

Lifetime Member

Supporting Member

Club Contributor

X2I would say recheck it just for peace of mind, but there will be a light tapping when properly adjusted. Just make sure it's at room temp when you recheck.

Rechecked and I believe it looks good. The confusion for me when using the clearance gauges is inserting it in the gap and then moving around. Adjust when gauge is in the gap. When inserting and removing the gauge interferes a little with the housing causing a false reading.

Russ989

Land of the free because of the Brave! 🇺🇸

Lifetime Member

Supporting Member

Club Contributor

Once in the gap you can adjust the valve tappet but keep in mind it won’t take much at all to get within spec. You only want to feel a little resistance.Rechecked and I believe it looks good. The confusion for me when using the clearance gauges is inserting it in the gap and then moving around. Adjust when gauge is in the gap. When inserting and removing the gauge interferes a little with the housing causing a false reading.

advertisement

Similar threads

- Replies

- 0

- Views

- 596

- Replies

- 0

- Views

- 494

S

- Replies

- 23

- Views

- 3K