DG Rider

Member: Triple Clutch Club

Lifetime Member

Disclaimer: This guide was intended to help walk 700 owners through the valve adjustment procedure. You must decide if you have the skills necessary to perform this procedure, and act accordingly. (Translation: This does not make a lube tech a master technician, and if you screw up your machine, I take no responsibility. Know your limits.)

Additionally, it was written for a 2014 M/Y machine (the only year in existence at the time). The 2015 and newer are almost certainly identical spec wise, but it is up to YOU to confirm this before proceeding.

Now that that's out of the way...

I finally got around to putting together a valve adjustment guide for Pioneer owners who are willing to give it a go yourselves. If you are not comfortable with any part of this, i suggest you take the machine to your dealer ( or indy shop ) and let them perform the task. If you want to save some coin, you could always strip the plastics yourself, and the shop should give you a break.

Unfortunately, some shops never perform a valve adjustment during a "service" unless you request it.

You will need basic metric hand tools with metric sockets and wrenches of 8, 10, 14mm, etc. A 17mm is needed to turn the crank. A flat and Phillips screwdriver as well.

You will also need a 6mm hex bit or wrench for the timing mark inspection hole plug. DO NOT USE A TORX OR "CLOSE-TO-IT" STANDARD HEX, or you will strip out the plug.

Less common tools you will need:

You will need a 24mm socket or wrench for the crankshaft hole cap ( to turn the engine over ). Socket would be easier, and can be bought individually at Sears for not much $$$.

A set of feeler gauges with the proper sizes: .15mm ( .006 in ) & .32mm ( .013 in ). Cheap gauges may not have these sizes.

A torque wrench with the proper range of 17 newton meters ( N.m ) or 155 inch pounds ( in-lbs ). 13 foot pounds ( lbf.ft ) is also the equivalent, but it is rare to see a foot pounds wrench that goes this low. You want these numbers in the middle of the TW's range, as accuracy diminishes at the extremes of a TW's range. This is to torque the adjusting tappet lock-nuts, which i strongly recommend.

You will also be removing about 1 million of those Honda plastic rivets. I use a flat screwdriver to remove them and stab my fingers at the same time. Honda does make a tool for this. I have never been tempted to buy it...until i worked on the Pioneer.

Finally, you will want to wear quality gloves, be it latex or whatever. Used oil causes skin cancer, and at the very least makes your skin look horrible. Latex also keeps the blood in when you stab your fingers while removing Honda rivets.

Valve adjustment intervals: First 100 miles or 20 hours, and every 600 miles/100 hours thereafter. Factory adds the cover your ass line of "...otherwise, only if noisy." to those intervals. Valves are to be adjusted at "room temperature"...IE cold. I let mine sit overnight.

Abbreviations we will be using:

FSM - Factory service manual.

TDC - Top dead center on the compression stroke. This is when the piston is at its highest point of travel during the compression stroke. This is where we adjust the valves.

Tight valve - one whose adjusting tappet to valve tip clearance is too small.

Loose valve - one whose adjusting tappet to valve tip clearance is too great.

CYA - Cover your ass!

1st, wash your machine ( if you plan on it ) to prevent crap from falling in the open engine. Also plan on changing the oil afterwards for the same reason. Always cover openings if possible when not using them to prevent this. As you can see from the pics, i skipped the whole wash thing.

Most time consuming is simply to reach the valves. 2 seat owners may not need to do some of these steps.

Read through this whole post BEFORE you start!

Lets get started....

Remove the airbox cover (which is NOT present in this pic

), NOT the airbox lid!

), NOT the airbox lid!

Then remove the seat bottom...

..and backrest...

Next, remove the plastic trim behind the driver's seat. This will start your adventure with the rivets. One screw as well...

Next you will remove all the rivets and screws from the drivers-side plastic surround on the top of the seating frame ( this is the plastic under the seat ), and remove the plastic.

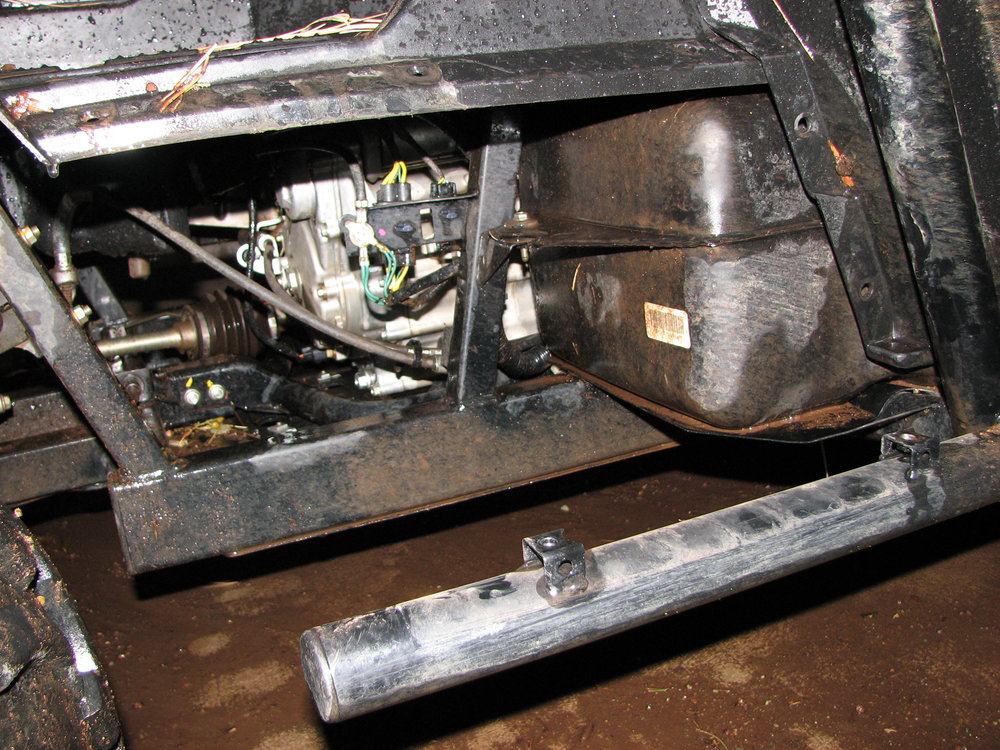

Move to the passengers side rear step ( 4P only ) and remove it for access to the timing mark plug and crank access hole plug. If this is your 1st time, you might also want to remove the floorboard as well...but once you know what you are looking for, you won't need to remove the floorboard...

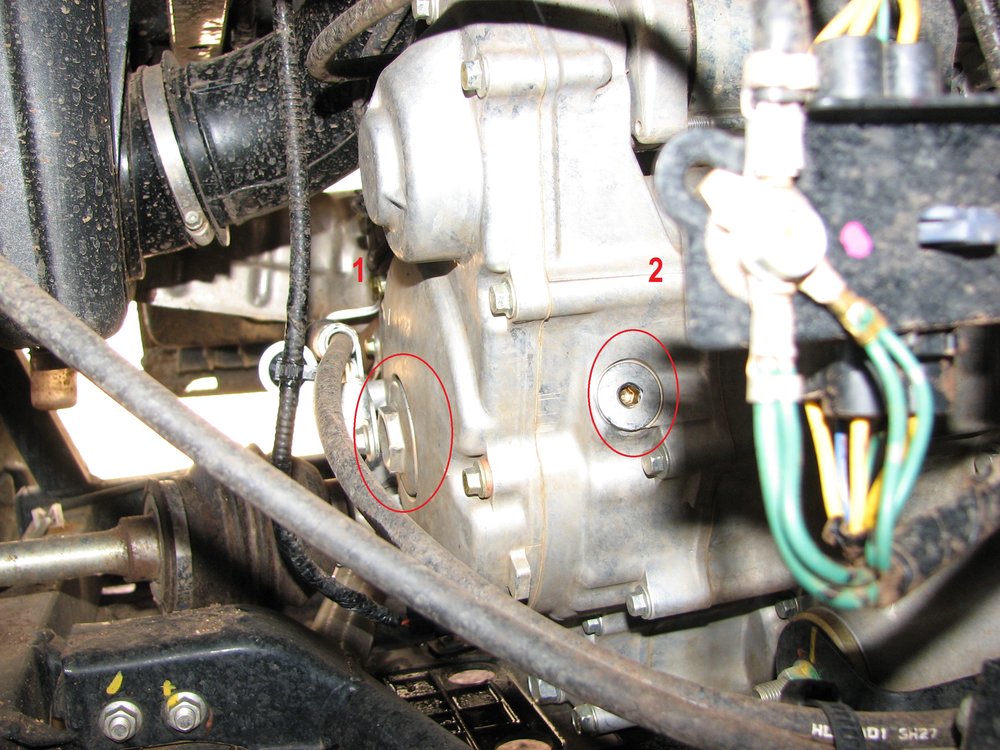

Using a 24mm socket or wrench, remove the crank access hole plug (1). Use a 6mm hex bit/wrench and remove the timing mark inspection plug (2)...

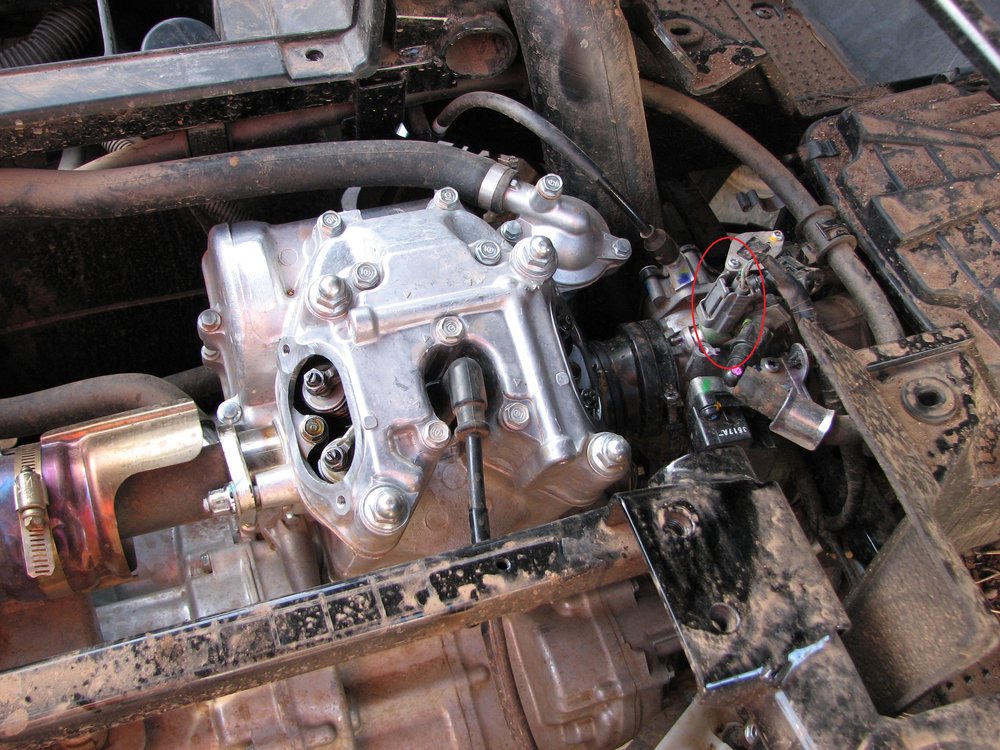

Now, move back to the top of the machine and remove the 2 valve access caps ( arrows ) with 2 each 8mm bolts...

Now you need to find TDC!

Finding TDC:

This is the easiest way to do this for me, and i can't see how any other way would be easier...

Insert a clean 17mm socket into the crank access hole on the back of the engine, and rotate the engine ( clock-wise only! ) until you see the intake valves open and close. If you don't know which are the intake, stop and take the machine to a dealer at once.

Anyway, once the intakes are closed, you are only approximately 180 degrees of crank rotation from TDC. Get down and start looking through the timing mark access hole as you slowly rotate the crank. You will need some light to see what you need to see, so a head-band type light is very useful here.

On the right ( vehicle front ) side of the hole you will see a small protrusion cast in the engine case in the vertical center of the hole. This is your alignment mark, and try as i might, i could NOT get a good picture of this.

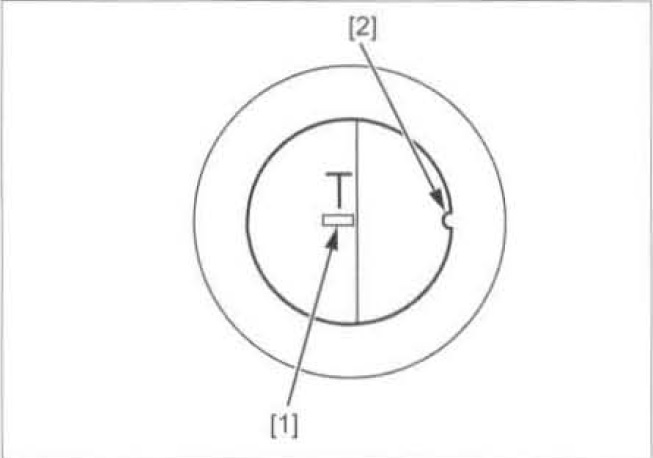

As you rotate the crank, at some point you will start to see some letters and lines cast into the flywheel. You may also feel some increased resistance from compression. The 1st thing you will see is an "F", followed by a line. This is your key to the fact that you are very close to TDC. Shortly after the 1st line, you will see another line with a "T" above it. This 2nd line is what you want to align with the protrusion cast into the engine case...

BE VERY GENTLE WHILE ROTATING PAST THE "F" MARK, as the engine gets very easy to rotate at this point, and its easy to go past the "T" line, and once you do that, you get to start all over ( DO NOT ROTATE THE ENGINE BACKWARDS, EVEN A TINY AMOUNT ).

So this is the pattern with left being the bottom of the hole, and everything in quotations is what you will see in the hole as you rotate:

[Bottom of hole] <<<crank rotation <<< " F | | T" [Top of hole].

This is from the service manual of how it will look...(Please note that the letters will be rotated 90 degrees from this diagram, with the tops facing the front of the machine !)

EDIT: Thanks to @Rinconruss we now have a nice pic of this!

If you did this right, you are now ready to adjust. As i stated before, the engine rotates very easily at this point, so gently remove the socket you have been using to rotate the crank, so it doesn't get turned by accident.

Now head back up top to the valve access holes. Push/pull up and down on the rocker arms. You should be able to feel a very, very tiny amount of movement in the arms before they contact the valve tips. You may also want to try to insert the smallest feeler gauge you have to check this. IF there is no play, you may have messed up on the TDC find procedure, and should repeat it.

IT IS possible, however, that the valves have tightened up ( reduced clearance ) this much, especially if you have been having starting/performance issues. Repeat the TDC procedure, and if there is still no play, then you likely just have valves that have tightened up considerably.

Adjusting clearances:

Adjustment specs:

Intake: .15mm +/- .02mm ( .006 +/- .001 in ).

Exhaust: .32mm +/- .02mm ( .013 +/- .001 in ).

Now we are to the hardest part of describing how to adjust valves, because it can be hard to put into words just what needs to be done here.

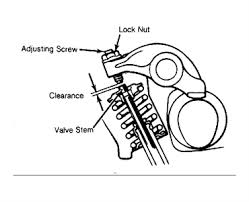

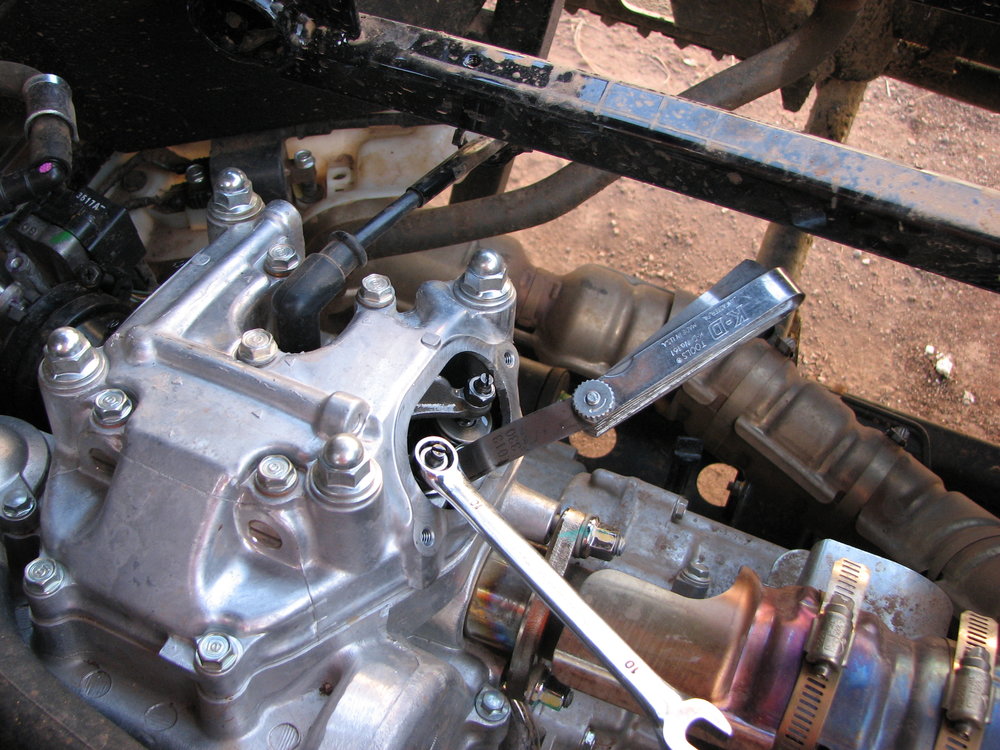

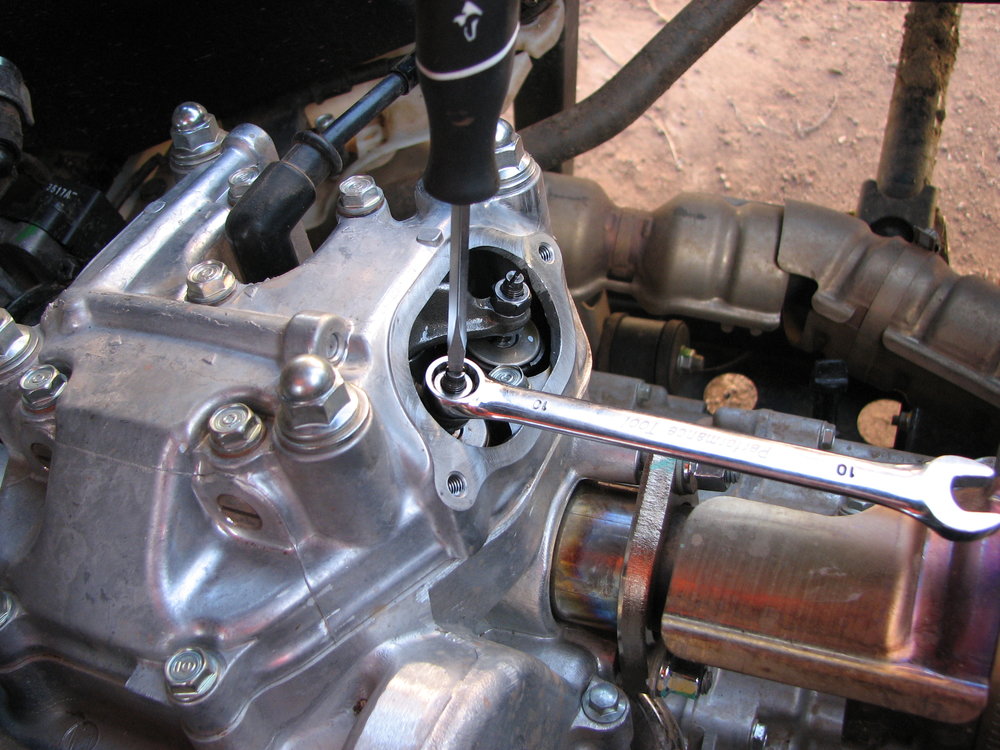

Study this picture...

...and you can see what we are trying to adjust here, but there are some pitfalls. We want to measure the gap between the valve tip and the adjusting tappet ( or screw, in this picture ). What we don't want to do is have the "feel" of that gap thrown off because of putting our feeler gauge in at an odd angle due to our access windows. This becomes more likely with thicker feeler gauges, so the exhaust side of the Pioneer can be a little difficult to judge. For this reason, i bend the tip of my feeler gauges a bit to get a good straight angle between the tappet and valve tip.

Select the proper feeler gauge for the valve you are trying to adjust, and try and insert it between the valve and tappet. If its the right size, it may be hard to insert at first, but should move easily after you get it started.

Again, the drag on the feeler can be hard to describe, and honestly, probably varies from person to person. Remember this one tip when it comes to valve adjustments: Unlike most things in life, when it comes to valve clearance, too loose is preferable to too tight. Loose valves ( within reason ) are likely to only make noise ( this is not a license to run way loose valves, BTW ). Tight valves are more likely to cause serious engine damage and performance issues.

Now, the best way I've heard the proper feeler drag described is to imagine pulling a sheet of paper out of a thick dictionary. The FSM also offers the tip of judging the drag while pulling the gauge, not pushing. If you get a light drag on the gauge, then you are lucky, and no adjustment is needed. Repeat for the other valves. If they are the same, button the machine back up and go buy a lotto ticket.

If the feeler gauge cannot be inserted, has a ton of drag or none at all, you are going to have to adjust the clearance. This is done by loosening the lock-nut and rotating the tappet with a flat screwdriver...

...If you are doing the intakes, you might want to unplug the fuel injector harness, since it takes up real estate that the wrench wants to occupy, and you don't want to break it off. Remember to plug this back up before turning the key on, or you'll get a code...

Remove your feeler gauges while adjusting the tappet screw, as you don't want to dimple them. Unfortunately, there is no hard and fast rule to doing this, and it doesn't take much of a turn to change the gap pretty significantly. Furthermore, tightening the lock-nut ( even while holding the tappet ) also changes the clearance minutely. Trial and error are really the only way to get this right, but you will quickly catch on...

Turn tappet, then snug down the lock-nut with a wrench. Re-check, until proper feel is obtained. It may take many tries to get it right...

Once you get the right feel, move on to any others that might need to be done.

Once done, i strongly recommend you use a torque wrench on these lock-nuts. If they come off, it will fubar something expensive pretty quickly. The last time a veteran Honda tech did this by "feel" i got lucky and only had the lock-nut land in a recess in the head of my VF500F Interceptor. Use a torque wrench.

Valve adjusting tappet lock-nut Torque: 17 N.m ( 1.7 kgf.m / 13 lbf.ft / 150 in.lbs ) Please the see note below on revised torque settings before torquing!

This is a "staged" shot. You should have a hand at the wrench head acting as a pivot...

Tip:

My service manual for the 450S Foreman lists this torque in a range of 144-150 inch pounds ( in.lbs ). It used the exact same adjusters and lock nuts. For reasons why you might want to use the lower setting, see the next tip...

Tip:

Experience has shown me that no matter how carefully your torque these lock-nuts, they eventually strip. Once the torque wrench makes its' torque, the nut should stop turning, and not turn again when you reapply the same amount of torque. If it turns every time you hit the same reading, it is stripping, and i do not trust it to stay put. At that point, i replace the tappet and lock-nut. They are cheap, and I'll post part numbers in the future.

NOTE: After repeatedly stripping the lock-nuts, I have revised this torque setting down to 130 in.lbs on my machine with no issues. The lock-nuts simply cannot repeatedly take the recommended spec for torque.

Not tip?

It used to be recommended that anytime you adjust "forked" rocker arms like the Pioneer has, a feeler gauge be used under BOTH tappets at all times. This obviously requires 2 sets of feeler gauges, and is done because if the rocker didn't contact both vales at exactly the same time, the rocker would twist slightly in the clearance it had on the rocker shaft, and might not result in perfectly adjusted valves.

I used to adhere to this religiously, but i have dropped that technique in modern times. For one thing, there is little room for two gauges on this machine, and for another, i believe machining clearances have improved since the 1st generation Honda V-4's ( notoriously sloppy valve-trains ) to the point where this is not really needed. Adjust both sides of the rocker as close to each other ( as far as drag ) as you can, and i feel you will be A-OK. FWIW, i have never seen a Honda FSM even mention using 2 sets of gauges.

Once torqued, i like to check clearances again as they could change ( especially if you aren't locking the nut down very tight with a wrench before torquing ). Then, I like to rotate the engine a few times, then repeat the TDC procedure, and re-check clearances. Sometimes messing with the rocker-arms throws the valve-train out of alignment a bit, which can throw off the clearance. My 450 did this, and i always had to make the initial adjustments a little tight to get the final where i wanted it.

I have not seen this on my Pioneer, so it should stay the same. This last check is the final word on adjustments, and if all passes, you are done, and can button it up, change the oil, and go riding.

In operation, a light ticking noise is normal, so don't flip out if you hear that. No noise would be a bigger concern.

There you have the Pioneer valve adjustment. Just put everything back together.

Finally,

If you found this guide useful, PLEASE leave some feedback or just say thanks. This will show that it is being used and bump it for new users to see!

Thanks.

Additionally, it was written for a 2014 M/Y machine (the only year in existence at the time). The 2015 and newer are almost certainly identical spec wise, but it is up to YOU to confirm this before proceeding.

Now that that's out of the way...

I finally got around to putting together a valve adjustment guide for Pioneer owners who are willing to give it a go yourselves. If you are not comfortable with any part of this, i suggest you take the machine to your dealer ( or indy shop ) and let them perform the task. If you want to save some coin, you could always strip the plastics yourself, and the shop should give you a break.

Unfortunately, some shops never perform a valve adjustment during a "service" unless you request it.

You will need basic metric hand tools with metric sockets and wrenches of 8, 10, 14mm, etc. A 17mm is needed to turn the crank. A flat and Phillips screwdriver as well.

You will also need a 6mm hex bit or wrench for the timing mark inspection hole plug. DO NOT USE A TORX OR "CLOSE-TO-IT" STANDARD HEX, or you will strip out the plug.

Less common tools you will need:

You will need a 24mm socket or wrench for the crankshaft hole cap ( to turn the engine over ). Socket would be easier, and can be bought individually at Sears for not much $$$.

A set of feeler gauges with the proper sizes: .15mm ( .006 in ) & .32mm ( .013 in ). Cheap gauges may not have these sizes.

A torque wrench with the proper range of 17 newton meters ( N.m ) or 155 inch pounds ( in-lbs ). 13 foot pounds ( lbf.ft ) is also the equivalent, but it is rare to see a foot pounds wrench that goes this low. You want these numbers in the middle of the TW's range, as accuracy diminishes at the extremes of a TW's range. This is to torque the adjusting tappet lock-nuts, which i strongly recommend.

You will also be removing about 1 million of those Honda plastic rivets. I use a flat screwdriver to remove them and stab my fingers at the same time. Honda does make a tool for this. I have never been tempted to buy it...until i worked on the Pioneer.

Finally, you will want to wear quality gloves, be it latex or whatever. Used oil causes skin cancer, and at the very least makes your skin look horrible. Latex also keeps the blood in when you stab your fingers while removing Honda rivets.

Valve adjustment intervals: First 100 miles or 20 hours, and every 600 miles/100 hours thereafter. Factory adds the cover your ass line of "...otherwise, only if noisy." to those intervals. Valves are to be adjusted at "room temperature"...IE cold. I let mine sit overnight.

Abbreviations we will be using:

FSM - Factory service manual.

TDC - Top dead center on the compression stroke. This is when the piston is at its highest point of travel during the compression stroke. This is where we adjust the valves.

Tight valve - one whose adjusting tappet to valve tip clearance is too small.

Loose valve - one whose adjusting tappet to valve tip clearance is too great.

CYA - Cover your ass!

1st, wash your machine ( if you plan on it ) to prevent crap from falling in the open engine. Also plan on changing the oil afterwards for the same reason. Always cover openings if possible when not using them to prevent this. As you can see from the pics, i skipped the whole wash thing.

Most time consuming is simply to reach the valves. 2 seat owners may not need to do some of these steps.

Read through this whole post BEFORE you start!

Lets get started....

Remove the airbox cover (which is NOT present in this pic

Then remove the seat bottom...

..and backrest...

Next, remove the plastic trim behind the driver's seat. This will start your adventure with the rivets. One screw as well...

Next you will remove all the rivets and screws from the drivers-side plastic surround on the top of the seating frame ( this is the plastic under the seat ), and remove the plastic.

Move to the passengers side rear step ( 4P only ) and remove it for access to the timing mark plug and crank access hole plug. If this is your 1st time, you might also want to remove the floorboard as well...but once you know what you are looking for, you won't need to remove the floorboard...

Using a 24mm socket or wrench, remove the crank access hole plug (1). Use a 6mm hex bit/wrench and remove the timing mark inspection plug (2)...

Now, move back to the top of the machine and remove the 2 valve access caps ( arrows ) with 2 each 8mm bolts...

Now you need to find TDC!

Finding TDC:

This is the easiest way to do this for me, and i can't see how any other way would be easier...

Insert a clean 17mm socket into the crank access hole on the back of the engine, and rotate the engine ( clock-wise only! ) until you see the intake valves open and close. If you don't know which are the intake, stop and take the machine to a dealer at once.

Anyway, once the intakes are closed, you are only approximately 180 degrees of crank rotation from TDC. Get down and start looking through the timing mark access hole as you slowly rotate the crank. You will need some light to see what you need to see, so a head-band type light is very useful here.

On the right ( vehicle front ) side of the hole you will see a small protrusion cast in the engine case in the vertical center of the hole. This is your alignment mark, and try as i might, i could NOT get a good picture of this.

As you rotate the crank, at some point you will start to see some letters and lines cast into the flywheel. You may also feel some increased resistance from compression. The 1st thing you will see is an "F", followed by a line. This is your key to the fact that you are very close to TDC. Shortly after the 1st line, you will see another line with a "T" above it. This 2nd line is what you want to align with the protrusion cast into the engine case...

BE VERY GENTLE WHILE ROTATING PAST THE "F" MARK, as the engine gets very easy to rotate at this point, and its easy to go past the "T" line, and once you do that, you get to start all over ( DO NOT ROTATE THE ENGINE BACKWARDS, EVEN A TINY AMOUNT ).

So this is the pattern with left being the bottom of the hole, and everything in quotations is what you will see in the hole as you rotate:

[Bottom of hole] <<<crank rotation <<< " F | | T" [Top of hole].

This is from the service manual of how it will look...(Please note that the letters will be rotated 90 degrees from this diagram, with the tops facing the front of the machine !)

EDIT: Thanks to @Rinconruss we now have a nice pic of this!

If you did this right, you are now ready to adjust. As i stated before, the engine rotates very easily at this point, so gently remove the socket you have been using to rotate the crank, so it doesn't get turned by accident.

Now head back up top to the valve access holes. Push/pull up and down on the rocker arms. You should be able to feel a very, very tiny amount of movement in the arms before they contact the valve tips. You may also want to try to insert the smallest feeler gauge you have to check this. IF there is no play, you may have messed up on the TDC find procedure, and should repeat it.

IT IS possible, however, that the valves have tightened up ( reduced clearance ) this much, especially if you have been having starting/performance issues. Repeat the TDC procedure, and if there is still no play, then you likely just have valves that have tightened up considerably.

Adjusting clearances:

Adjustment specs:

Intake: .15mm +/- .02mm ( .006 +/- .001 in ).

Exhaust: .32mm +/- .02mm ( .013 +/- .001 in ).

Now we are to the hardest part of describing how to adjust valves, because it can be hard to put into words just what needs to be done here.

Study this picture...

...and you can see what we are trying to adjust here, but there are some pitfalls. We want to measure the gap between the valve tip and the adjusting tappet ( or screw, in this picture ). What we don't want to do is have the "feel" of that gap thrown off because of putting our feeler gauge in at an odd angle due to our access windows. This becomes more likely with thicker feeler gauges, so the exhaust side of the Pioneer can be a little difficult to judge. For this reason, i bend the tip of my feeler gauges a bit to get a good straight angle between the tappet and valve tip.

Select the proper feeler gauge for the valve you are trying to adjust, and try and insert it between the valve and tappet. If its the right size, it may be hard to insert at first, but should move easily after you get it started.

Again, the drag on the feeler can be hard to describe, and honestly, probably varies from person to person. Remember this one tip when it comes to valve adjustments: Unlike most things in life, when it comes to valve clearance, too loose is preferable to too tight. Loose valves ( within reason ) are likely to only make noise ( this is not a license to run way loose valves, BTW ). Tight valves are more likely to cause serious engine damage and performance issues.

Now, the best way I've heard the proper feeler drag described is to imagine pulling a sheet of paper out of a thick dictionary. The FSM also offers the tip of judging the drag while pulling the gauge, not pushing. If you get a light drag on the gauge, then you are lucky, and no adjustment is needed. Repeat for the other valves. If they are the same, button the machine back up and go buy a lotto ticket.

If the feeler gauge cannot be inserted, has a ton of drag or none at all, you are going to have to adjust the clearance. This is done by loosening the lock-nut and rotating the tappet with a flat screwdriver...

...If you are doing the intakes, you might want to unplug the fuel injector harness, since it takes up real estate that the wrench wants to occupy, and you don't want to break it off. Remember to plug this back up before turning the key on, or you'll get a code...

Remove your feeler gauges while adjusting the tappet screw, as you don't want to dimple them. Unfortunately, there is no hard and fast rule to doing this, and it doesn't take much of a turn to change the gap pretty significantly. Furthermore, tightening the lock-nut ( even while holding the tappet ) also changes the clearance minutely. Trial and error are really the only way to get this right, but you will quickly catch on...

Turn tappet, then snug down the lock-nut with a wrench. Re-check, until proper feel is obtained. It may take many tries to get it right...

Once you get the right feel, move on to any others that might need to be done.

Once done, i strongly recommend you use a torque wrench on these lock-nuts. If they come off, it will fubar something expensive pretty quickly. The last time a veteran Honda tech did this by "feel" i got lucky and only had the lock-nut land in a recess in the head of my VF500F Interceptor. Use a torque wrench.

Valve adjusting tappet lock-nut Torque: 17 N.m ( 1.7 kgf.m / 13 lbf.ft / 150 in.lbs ) Please the see note below on revised torque settings before torquing!

This is a "staged" shot. You should have a hand at the wrench head acting as a pivot...

Tip:

My service manual for the 450S Foreman lists this torque in a range of 144-150 inch pounds ( in.lbs ). It used the exact same adjusters and lock nuts. For reasons why you might want to use the lower setting, see the next tip...

Tip:

Experience has shown me that no matter how carefully your torque these lock-nuts, they eventually strip. Once the torque wrench makes its' torque, the nut should stop turning, and not turn again when you reapply the same amount of torque. If it turns every time you hit the same reading, it is stripping, and i do not trust it to stay put. At that point, i replace the tappet and lock-nut. They are cheap, and I'll post part numbers in the future.

NOTE: After repeatedly stripping the lock-nuts, I have revised this torque setting down to 130 in.lbs on my machine with no issues. The lock-nuts simply cannot repeatedly take the recommended spec for torque.

Not tip?

It used to be recommended that anytime you adjust "forked" rocker arms like the Pioneer has, a feeler gauge be used under BOTH tappets at all times. This obviously requires 2 sets of feeler gauges, and is done because if the rocker didn't contact both vales at exactly the same time, the rocker would twist slightly in the clearance it had on the rocker shaft, and might not result in perfectly adjusted valves.

I used to adhere to this religiously, but i have dropped that technique in modern times. For one thing, there is little room for two gauges on this machine, and for another, i believe machining clearances have improved since the 1st generation Honda V-4's ( notoriously sloppy valve-trains ) to the point where this is not really needed. Adjust both sides of the rocker as close to each other ( as far as drag ) as you can, and i feel you will be A-OK. FWIW, i have never seen a Honda FSM even mention using 2 sets of gauges.

Once torqued, i like to check clearances again as they could change ( especially if you aren't locking the nut down very tight with a wrench before torquing ). Then, I like to rotate the engine a few times, then repeat the TDC procedure, and re-check clearances. Sometimes messing with the rocker-arms throws the valve-train out of alignment a bit, which can throw off the clearance. My 450 did this, and i always had to make the initial adjustments a little tight to get the final where i wanted it.

I have not seen this on my Pioneer, so it should stay the same. This last check is the final word on adjustments, and if all passes, you are done, and can button it up, change the oil, and go riding.

In operation, a light ticking noise is normal, so don't flip out if you hear that. No noise would be a bigger concern.

There you have the Pioneer valve adjustment. Just put everything back together.

Finally,

If you found this guide useful, PLEASE leave some feedback or just say thanks. This will show that it is being used and bump it for new users to see!

Thanks.

Last edited: