I'm hesitant to get involved in this one....but, I work on Honda outboards, and I can tell you that some of the torque-specs are a bit sketchy for the smaller fasteners- anything that uses a 10mm, or 12mm wrench with the actual thread diameter comparable to 1/4 or 5/16 bolts. I've had them strip, or break using Honda's specs, (with me wincing in advance, just knowing the bloody fastener was about to break..)so like the other guys said, it's a 'feel' thing. Don't know if it's the same for the power-sports side, but I can tell you, if you put 9 lbs, or even 7 in some cases, on a normal 10mm (socket size) bolt, it's not going to do it more than a couple times without breaking, or distorting something- particularly in aluminum. I can say without hesitation for instance, the torque spec for the skid plate bolts is just plain too high. If you're concerned that a fastener that has to be removed and installed many times may come loose, put some medium, or low strength lok-tite on the threads. I mention the skid plates because I've had mine off so many times... Just avoid over-tightening fasteners as much as possible!

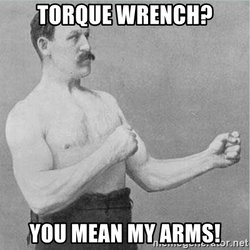

On the other hand, there are some who shouldn't be allowed near a bolt without a torque-wrench. If you know you're one of those people, get at least, a good inch-pound wrench for the small fasteners, and learn how to use it!