PaulF

/\/\/\/\/\/\/\/\/\/\/\/\

Lifetime Member

My large wire harness mod works good at eliminating the dangerous loss of assist in tight turn scenarios in dirt/trail/sand and helps somewhat with other issues but does not address the issues that some of us have on slower, hard surface conditions. I love to rock crawl and the paltry 210 watt OEM steering is just not enough for a nearly 1 ton machine so I decided to look for something better.

SATV has a "400 Watt" universal kit. I decided to try and see if it would fit and it turned out to be a moderate (7 out of 10) fabrication for the Talon.

Got the installation finished but before we go into detail, let me point out a couple things...

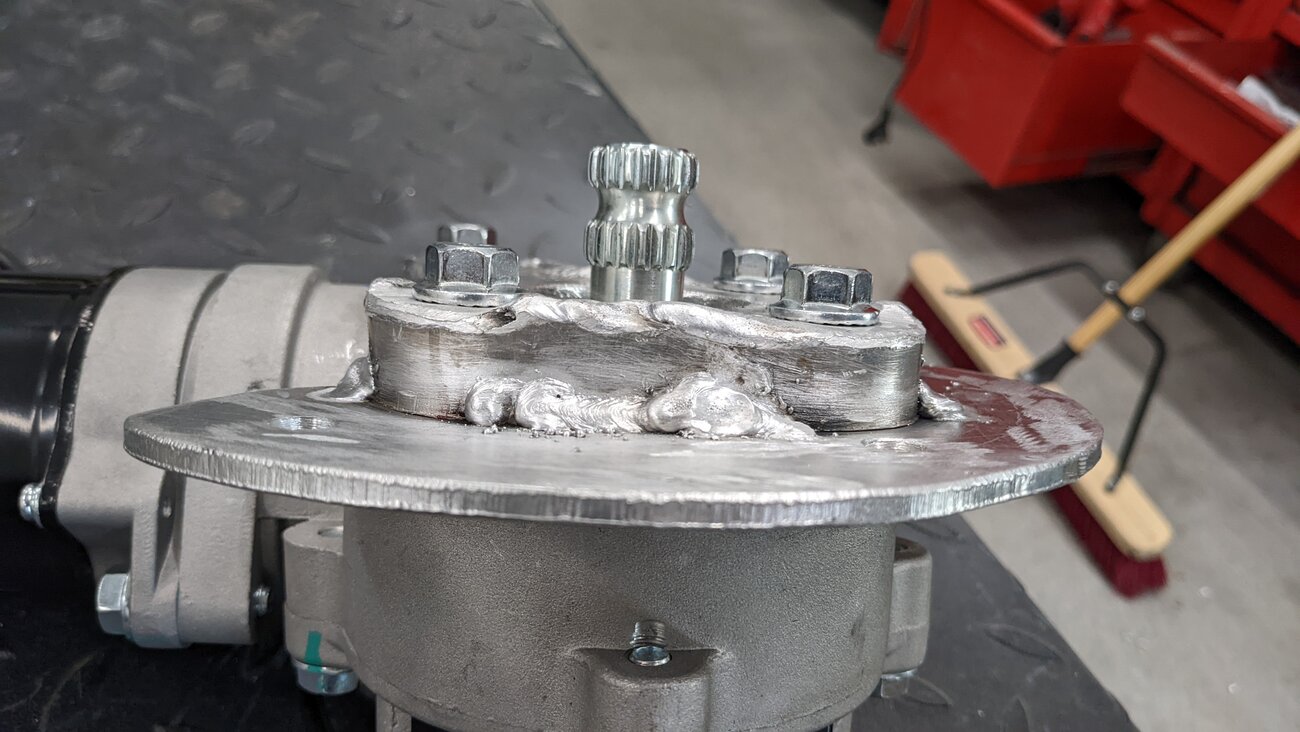

Here is the drop bracket bolted to the motor. It is so tight, I was not able to weld in the corners because it wouldn't fit if I did. A flat bracket will not have this problem...

It is so tight, I had to countersink one of the mount bolts. A flat bracket will not have this problem...

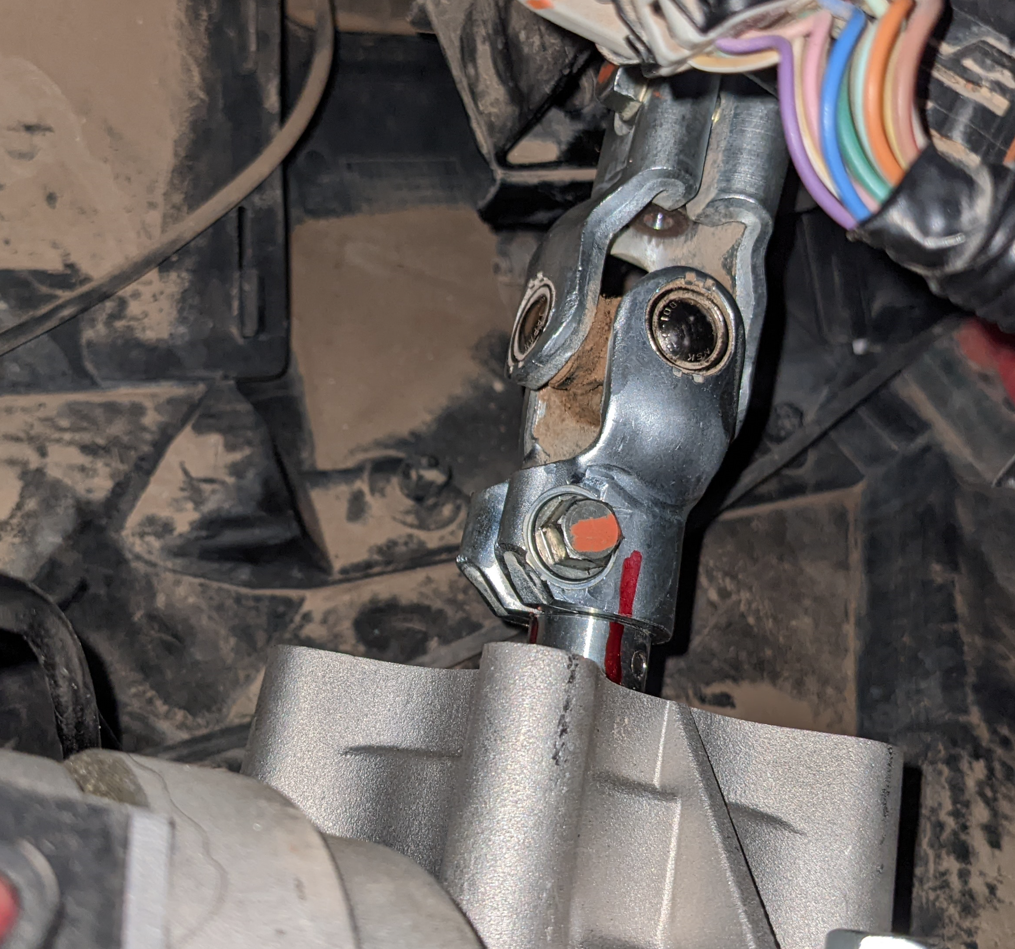

Factory Middle Shaft installed without modifications. You can see my clock marks that I talked about above...

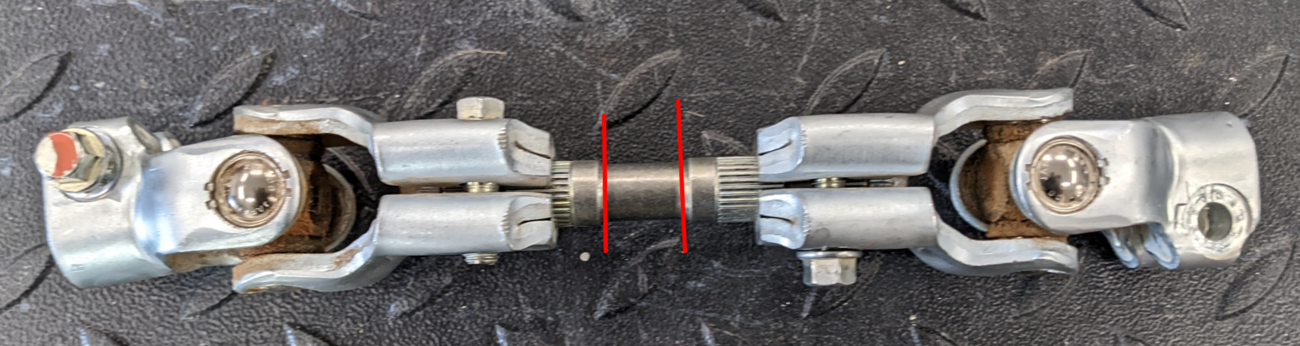

The rack is smaller than the other shafts so for the bottom shaft, I had to swap the lower end from the OEM shaft to the SATV shaft. This is tricky and you can easily ruin the little u-joint cups. You must chisel/grind/drill the stake marks or you will destroy the cups trying to press them out...

The output from the steering motor is some odd proprietary 22mm X 20 spline. I had to remove the shaft from that and weld it to the input shaft I modified above.

This is the lower shaft (from the motor to the rack) welded but before paint. It consists of parts from the SATV upper shaft, lower shaft and the OEM end...

Power must come from the OEM winch wires. If you have a winch or are using that wire to tie in a second battery then just connect it there. If you are not using that wire, you will need a terminal post and also to connect the winch wire in the battery box. The ground is simply connected to one of the mount bolts (the Talon frame is well grounded). If your SATV kit has 6+ foot power wires, I suggest you cut them down.

The white wire must hook to a key on power source.

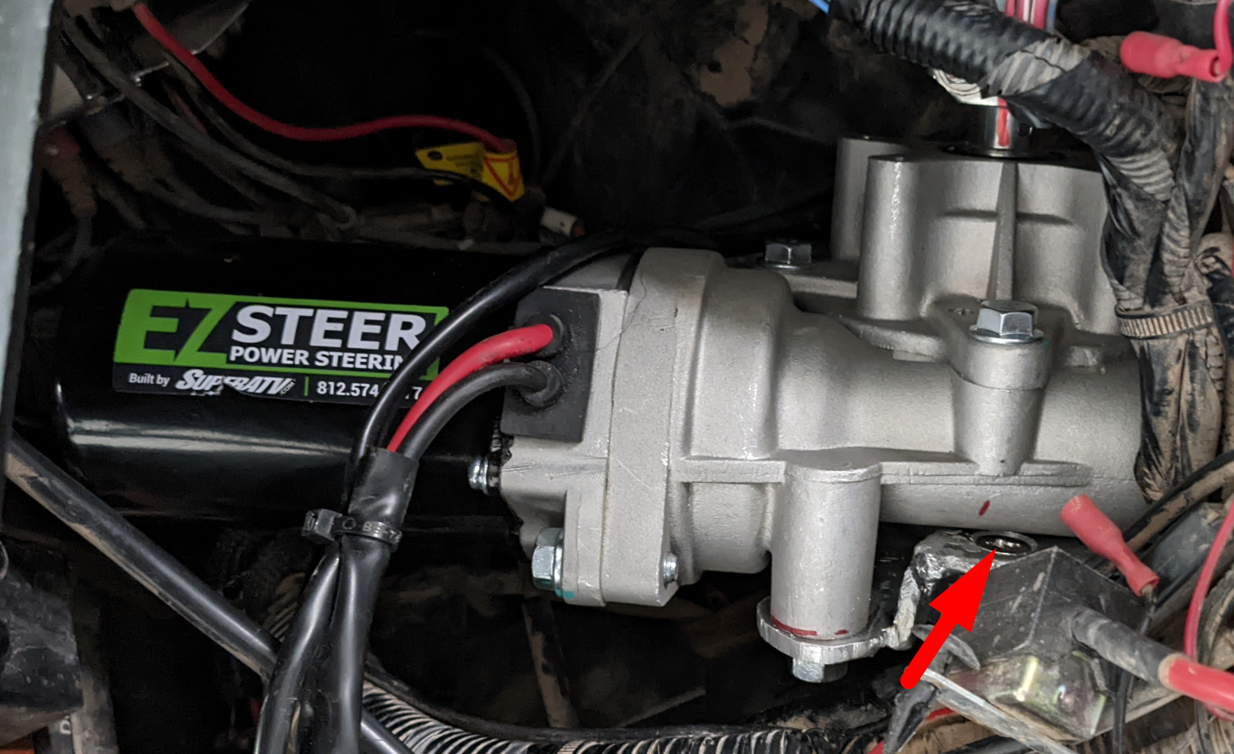

The optional blue VSS wire can hook to the pink wire on the original PS ECU. You can also tap into it at the big square plug just above the steering motor here...

BELOW IS FOR REFERENCE ONLY!!! I did not do it this way but suggest that you explore this option. It would probably be better to build a flat mount plate, build the lower shaft as I explain above (but slightly longer) and and modify the OEM middle shaft something like this...

SATV has a "400 Watt" universal kit. I decided to try and see if it would fit and it turned out to be a moderate (7 out of 10) fabrication for the Talon.

Got the installation finished but before we go into detail, let me point out a couple things...

- First off, although this unit only tested around 310 watts, don't be discouraged. It must be geared different because it is only 50% more watts but provides twice the torque that the OEM motor does. This unit is pretty powerful and in my opinion, this is actually better because it only uses 50% more watts and provides twice the assist torque. I am kind of glad it isn't really 400 watts.

- If you can afford it and can wait until they have more in stock, just buy the bolt in Raceco kit (it uses the same motor and ECU). Fabbing your own from this kit takes some know how, precise measurements, some basic equipment and a welder (and a lathe would be nice too but not necessary) and a LOT of time and patience If you are like me and love to mod, then go for it, it isn't really that hard.

- The unit is huge and powerful. It drives effortlessly at 12 PSI and you can definitely tell when the tires are at 4 PSI on asphalt but still provides ample assist at low pressures, even when stopped. It does NOT bind up when you are against a hard obstacle (I tested on 12" high parking stop at my local school) so I suspect a vast improvement when rock crawling. It provides consistent assist from lock to lock (unlike the OEM system).

- It does take slightly more effort to trigger the torque sensor so it is less sensitive but more powerful (if that makes any sense). At the lower torques it is similar to stock but to get the higher output torque, you have to apply slightly more input torque. The OEM unit stop adding assist at 45 inch pound input while the SATV unit utilizes up to 60 inch pounds of input. This isn't anything bad, just different.

- The torque sensor on the OEM is better (tighter) so this unit does have a very slight amount of play at center. Only noticed it on a straight long street, probably never notice off road. Again, nothing bad, just want everyone reading to know what to expect.

- The speed sensor works and varies the assist. At 12 psi, the assist variation at speed works adequately when connected and makes corners much safer. Without the VSS connected, the car is a bit twitchy and you can dangerously oversteer going into a corner. However, it is a little annoying when running low tire pressure like when rock crawling. At 4 PSI, there isn't enough assist when turning while braking into a corner (somewhat like the OEM but not quite as bad) but it is acceptable with the VSS disconnected and the assist at full power at all speeds. For that reason, I connected the VSS feed to a switch so I can disengage it when running low tire pressure.

- This think can produce some HEAT!!! The ECU more so than the motor so cooling may be required, especially if you have a full firewall like I do and no ventilation. I am working on this but have not come up with anything yet so I am running with the cowl off for testing.

- You can disable the OEM warning light or you can utilize it if you want. The OEM light is grounded to turn it off or you can wire a relay and let the SATV unit use it like I did.

- There is a clocking situation that you need to keep in mind. All the talon shafts and joints are 36 spline so no matter where you place the joints, everything always lines up but the output shaft of the SATV unit is 20 spline. This means that there are only 4 positions that will be correct to keep the steering wheel perfectly centered to the rack. If you don't clock the input and output joints correctly, you can be up to 8 degrees off and with what appears to be a centered steering wheel will net you a rig that will turn sharper one way and you won't be able to correct it by moving the wheel. This is easily avoided if you make sure the yokes are clocked correctly. If the yokes are not aligned, you just need to rotate them both on their shaft (output between 1 and 4 teeth) until they are correct then mark the shafts so you put it together correctly.

- I suggest you NOT do it exactly the way I did. I wanted to preserve the OEM parts in case it didn't work as expected so I "made it fit" with the middle shaft and joints and it made things much more complex than they needed to be. I learned as I went along and it was too late to change the direction I took. For that reason, I will show how I installed it in basic terms and what I would do different if I were to do it again.

Here is the drop bracket bolted to the motor. It is so tight, I was not able to weld in the corners because it wouldn't fit if I did. A flat bracket will not have this problem...

It is so tight, I had to countersink one of the mount bolts. A flat bracket will not have this problem...

Factory Middle Shaft installed without modifications. You can see my clock marks that I talked about above...

The rack is smaller than the other shafts so for the bottom shaft, I had to swap the lower end from the OEM shaft to the SATV shaft. This is tricky and you can easily ruin the little u-joint cups. You must chisel/grind/drill the stake marks or you will destroy the cups trying to press them out...

The output from the steering motor is some odd proprietary 22mm X 20 spline. I had to remove the shaft from that and weld it to the input shaft I modified above.

This is the lower shaft (from the motor to the rack) welded but before paint. It consists of parts from the SATV upper shaft, lower shaft and the OEM end...

Power must come from the OEM winch wires. If you have a winch or are using that wire to tie in a second battery then just connect it there. If you are not using that wire, you will need a terminal post and also to connect the winch wire in the battery box. The ground is simply connected to one of the mount bolts (the Talon frame is well grounded). If your SATV kit has 6+ foot power wires, I suggest you cut them down.

The white wire must hook to a key on power source.

The optional blue VSS wire can hook to the pink wire on the original PS ECU. You can also tap into it at the big square plug just above the steering motor here...

BELOW IS FOR REFERENCE ONLY!!! I did not do it this way but suggest that you explore this option. It would probably be better to build a flat mount plate, build the lower shaft as I explain above (but slightly longer) and and modify the OEM middle shaft something like this...

Last edited: