I have read that changing the cap solved the problem for some. I’m going to order one. Not even going to test the old one.Last summer I purchased a used 2016 1000-5 and had the same issues. Boiling over constantly and fan not working. After looking at it the fan was junk and I replaced that. Then took it out on a long ride a few weeks later and hit a couple times 3 bars, granted I was up like 10k elevation. I then burped the system used a professional air evacuation system for cooling systems and thought that would work. Took my machine on another ride and nope it still boils over. Last resort was try another radiator cap and wouldn’t you know it that was a fix. Have had no boiling in over 8 months and have ridden it pretty hard.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Did you happen to test the old or new cap in hot water, to see what temperature it opened? I bought a new cap, but didnt install it last summer because I tested my old one and it opened at the right temperature (cant remember what it was right now).I have read that changing the cap solved the problem for some. I’m going to order one. Not even going to test the old one.

G

Do you hear the fan running continuously when it’s at three bars?History: 2019 P5 LE

Never! Mudded. Never in water deeper than 6" while crossing creek

Radiator is clean and debris free

Fan Always seems to come on

Boiled over last September Riding slowly while scoping Elk

Dealer drained coolant and pumped in all new. Burped system

1200 miles on machine. riding a few days ago going slowly 4-6 mph for an extended period of time approx. 40 min. up rocky trail.

Running Bilge fan all during this climb to reduce heat in engine compartment

Hit 3 bars on the temp gauge WTF! No boil over. Maybe because as soon as I saw 3 bars I shut it down

Riding at this speed is 20% +/- of the time

Question: is this normal under these riding conditions?

My confidence is pretty low in this machines reliability right now. I don't want a machine that requires me to ride above 15 mph so it stays cool enough to not boil over or over heat

Any suggestions that have a proven history to fix this problem would be appreciated

DG Rider

Member: Triple Clutch Club

Lifetime Member

I have read that changing the cap solved the problem for some. I’m going to order one. Not even going to test the old one.

The cap doesn't open with temp, it opens with pressure. You guys are thinking of the thermostat. The "1.1" is the pressure in bars (roughly 15.9 psi).Did you happen to test the old or new cap in hot water, to see what temperature it opened? I bought a new cap, but didnt install it last summer because I tested my old one and it opened at the right temperature (cant remember what it was right now).

G

I lug mine all the time in 100 degree weather, mines a 2016 deluxe 5.Never have any problems.however never have the bars showing I hear the fan cycling. But not staying on constantly, if I hear it running I don’t shut it off till I hear the fan shut off.Dealer here says it was done according to their computer. They will get another chance on Monday.

This will get figured out or it will get sold. Either way I won’t ride a machine that I can’t trust.

On the other hand if you guys tell me that the Pioneer is a machine that cannot be lugged around then I will give some thought to modifying my riding style.

thanks

radiator caps work on psi,are u guys talking about the thermostat? When it comes to passenger cars and overheating, the thermostat is the first thing to look at , yet nobody brings it up on these threads about the pioneer overheating.I assume they have a thermostat.Did you happen to test the old or new cap in hot water, to see what temperature it opened? I bought a new cap, but didnt install it last summer because I tested my old one and it opened at the right temperature (cant remember what it was right now).

At three bars it was a hot smell that I noticed first. Then I looked at the temp gauge and saw three bars. First thing I check is the fan running? Yes it was. Next I switched on the bilge fan to move the heat off of the engine. Within 5 minutes it was back to 2 bars and never got above that again. Thing is with one boil over ( I know others have had more) and now this it’s hard to just enjoy the ride when you are constantly monitoring the temp gauge. Oh also it at times smells hot, kinda like the hot of a new machine burning in. I took it all apart after this last ride and found nothing unusual except the muffler looks like it’s gone through some serious heat treatment. This is where the odor seems to come from. I am going to pull the arrester out of it and see if it can tell me anything. Otherwise I have the extended warranty getting the necessary service work done and I might just say F it burn upDo you hear the fan running continuously when it’s at three bars?

At three bars it was a hot smell that I noticed first. Then I looked at the temp gauge and saw three bars. First thing I check is the fan running? Yes it was. Next I switched on the bilge fan to move the heat off of the engine. Within 5 minutes it was back to 2 bars and never got above that again. Thing is with one boil over ( I know others have had more) and now this it’s hard to just enjoy the ride when you are constantly monitoring the temp gauge. Oh also it at times smells hot, kinda like the hot of a new machine burning in. I took it all apart after this last ride and found nothing unusual except the muffler looks like it’s gone through some serious heat treatment. This is where the odor seems to come from. I am going to pull the arrester out of it and see if it can tell me anything. Otherwise I have the extended warranty getting the necessary service work done and I might just say F it burn up

Sorry for the rant.

G

If it were mine I would check into the thermostat,I’m sure it has one.Have the dealer change it under warranty.Sorry for the rant.

advertisement

If it were mine I would check into the thermostat,I’m sure it has one.Have the dealer change it under warranty.

I am taking it back to them on Friday to get this sorted out

S

So would the 2020s came with the flash already done?Honda was having some problems with the machine overheating when the fan wasn't coming on correctly. There is a computer reflash performed by the dealer that seemed to fix the problem, or at least fixed my issue. I believe it was for the 2017 and 2019 but don't quote me on that. According to other members of the forum, it also seemed to improve the shifting of the machine.

Here's a link to a different thread talking about it.

P1000 - Ecu Reflash for cooling fan? Or is it more!

After an overheating issue and a post on here. I was given the knowledge of a tech notice that Updates the fan "issue" since getting mine back here are some things that are completely different from before and after I have had 3 chances from yesterday to today to ride around the block and...hondasxs.com

O

I saw your post and thought I would share some things I have done and am going to do. My ride is a 2017 1000-5LE which will be 3 years old next month. The 2nd time I had it out it overheated and I immediately shut it down to cool and after getting it back to Quail camp (I also live in NE AZ) I started trouble shooting it. I realized early on that the fan switch was not reliable even after having it replaced under warranty. I also realized I needed a better gauge than the 4 bar set up. After shopping around I chose a Trail Tech digital temp gauge. It is compact, surface mounts on the dash in a very small space and has a built in battery guaranteed for at least 5 years. I had to build an in line hose device for the sender. I put it in the by pass hose which is a 12mm ID hose and no one makes a drop in mount for that size hose. I bought a brass fitting with 1/2" Female pipe threads straight through and a 1/8" Female pipe thread in the center. The tricky part was the adapter for the sensor because, in their infinite wisdom, Trail Tech uses a sensor with 1/8" Male British Pipe Thread. British pipe thread is not tapered like NPT is so the 2 are not compatible. I eventually found an adapter on Amazon that is 1/8" NPT Male X 1/8" BPT Female. I now know to the degree what the coolant temp is. I also installed a SPST toggle switch wired across the radiator fan wires so that I can turn the fan on any time I desire and I have a bilge fan mounted in the engine compartment. The bilge fan was more for keeping the passenger seat cool enough to sit on. Honda eventually installed better insulation so that I don't use the bilge fan much.

Now comes the improvement that I am getting ready to do. Years ago when I was young there were several companies that marketed waterless coolant. Today there is only one, Evans Waterless Coolant. It's a little pricey, by the time I bought 1.5 gallons of coolant, 1 gallon of prep fluid and a Chinese made anti freeze refractometer I'm in it about $140 including tax. I opted to go this route for 2 major reasons: !. The Evans Coolant has a boiling temp of 375 degrees F which is more than 100 degrees higher than anti freeze under extreme pressure. The manufacturer claims that their coolant operates at considerably lower pressures partly because of lower expansion rates. 2. Their coolant does not contain water and so totally inhibits corrosion and does not need to be replaced every 2 to 3 years. The prep fluid is only used on the first fill to help get all the water out of the system and the refractometer is to test and be certain that you got all the water out.

They claim, because there is no better fluid for heat transfer than water, that your machine may run a few degrees hotter than before but since the much higher boiling point prevents hot spots where water based coolant turns to steam, the protection for the engine is much better and operating pressures are much lower. The pioneer 1000 engine holds about 0.8 gallons of coolant so the 1.5 gallons gives me enough for the initial fill plus extra for future top off if needed.

I'll try and keep the thread informed of the performance along with any problems I encounter.

Old Gasser

Now comes the improvement that I am getting ready to do. Years ago when I was young there were several companies that marketed waterless coolant. Today there is only one, Evans Waterless Coolant. It's a little pricey, by the time I bought 1.5 gallons of coolant, 1 gallon of prep fluid and a Chinese made anti freeze refractometer I'm in it about $140 including tax. I opted to go this route for 2 major reasons: !. The Evans Coolant has a boiling temp of 375 degrees F which is more than 100 degrees higher than anti freeze under extreme pressure. The manufacturer claims that their coolant operates at considerably lower pressures partly because of lower expansion rates. 2. Their coolant does not contain water and so totally inhibits corrosion and does not need to be replaced every 2 to 3 years. The prep fluid is only used on the first fill to help get all the water out of the system and the refractometer is to test and be certain that you got all the water out.

They claim, because there is no better fluid for heat transfer than water, that your machine may run a few degrees hotter than before but since the much higher boiling point prevents hot spots where water based coolant turns to steam, the protection for the engine is much better and operating pressures are much lower. The pioneer 1000 engine holds about 0.8 gallons of coolant so the 1.5 gallons gives me enough for the initial fill plus extra for future top off if needed.

I'll try and keep the thread informed of the performance along with any problems I encounter.

Old Gasser

Where is the bypass hose you are using?

I just purchased the same temp indicator, but got it with a 25mm inline adaptor, and was going to install it in the inlet or outlet

hose to the radiator.

hose to the radiator.

I just purchased the same temp indicator, but got it with a 25mm inline adaptor, and was going to install it in the inlet or outlet

O

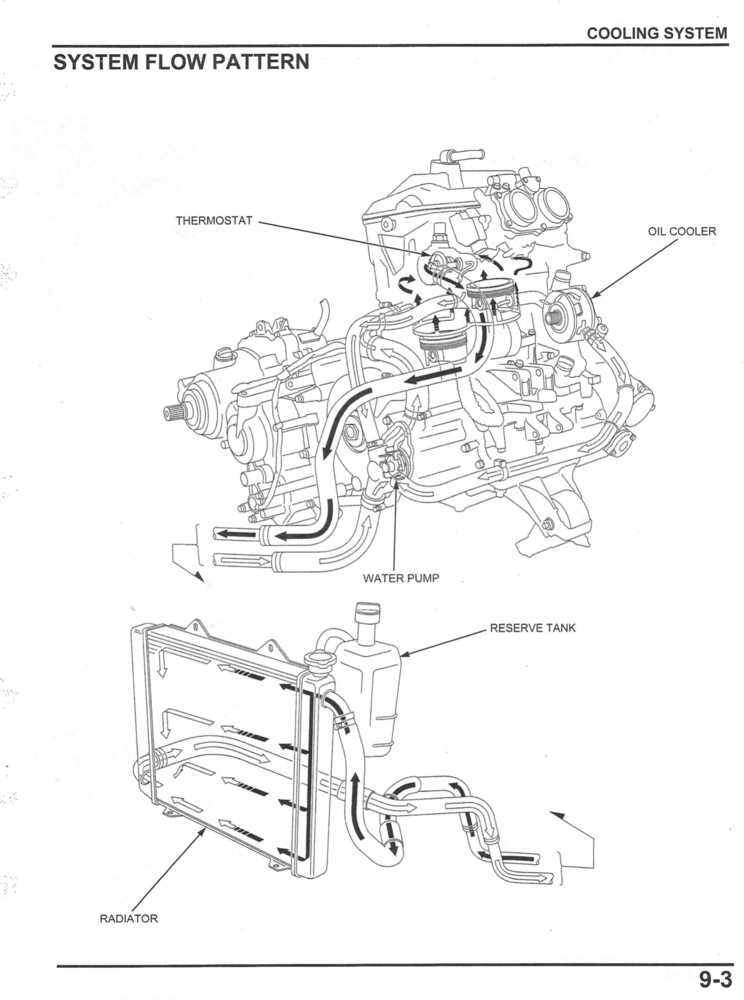

It is the 12 mm (ID) hose that bypasses the thermostat. In the engine diagram the flow arrows are grayed out and it hooks to the water pump. It is easily accessible under the seat. It has full flow when the thermostat is closed and less flow when the thermostat opens. The reason I chose that hose is that the coolant has just exited the engine so it is likely at. Its highest temperature.

Last edited:

O

Looking over the discussions on this thread I just wanted to comment on some of the observations: The radiator cap opens under excess pressure and is not dependent on temp. With the Evans coolant the coolant pressures are not supposed to exceed 5 psi where most high pressure caps are rated at 14 or 15 psi. Evans coolant says it is fine to continue using the 15 psi cap but it is not necessary. Gasoline engines generally run better at higher temps but coolant boiling is a limiting factor so keeping the coolant from boiling, which produces steam (vapor) which further limits cooling as heat can only transfer to liquid coolant, not vapor. By raising the boiling point to 375 degrees F. you are assured of having only liquid in the system and no hot spots where the liquid turns to steam which causes the local heat to get even hotter because it can not be removed from the engine. To me, this is a far superior and less expensive way to eliminate the cooling problem and significantly reduces the chance of hose or gasket failure due to greatly reduced coolant pressures.

O

Where is the bypass hose you are using?

I just purchased the same temp indicator, but got it with a 25mm inline adaptor, and was going to install it in the inlet or outletView attachment 204879 hose to the radiator.

O

I downloaded your coolant flow diagram and applied orange hi liter to show the location of the temp sensor. I also inked in a pointer to show the location. I used brass hose barbs 1/2" hose barb x 3/8" mip and threaded the hose barbs into a 3/8" brass pipe tee. In the center leg I used a 3/8" MIP x 1/8" FIP reducer bushing into which I installed the below listed adapter to make it accept the trail tech sensor. As luck would have it the sensor was just the right length to have the end positioned right in the middle of the coolant flow pattern

The link below is for the 1/8" MIP x 1/8" Female BPT adapter.

Old Gasser

The link below is for the 1/8" MIP x 1/8" Female BPT adapter.

Old Gasser

Can you tell me what strap that is that you have bolted to the front frame underneath for recovery? I have the bolts . . . looking for the strap.

Trail Gear 111295-KIT Rock Assault 6-Ply Limit Strap Rated at 9000 lbs Size: 32 | eBay

Find many great new & used options and get the best deals for Trail Gear 111295-KIT Rock Assault 6-Ply Limit Strap Rated at 9000 lbs Size: 32 at the best online prices at eBay! Free shipping for many products!

www.ebay.com

I found it cheaper somewhere but it’s same strap. It’s not going to break. But I only suggest it if you have the SATV frame stiffener. Take the front two spacers out and bolt in place.

advertisement