I tried like hell to find a high strength flanged bolt to replace with, the first time I addressed this. I had no luck with that. I ended up with these through Fastenal. Now I realized the bolt Snuff is using is stronger but the allen head steered me away. I just feel like you can put more torque on a hex head. (even though the specs say 42lbs. on the upper)

Another note to keep in mind for those of us that are not using the OEM flanged bolts and using washers, that can change the torque setting. In Snuffs setup no washers needed and the weld washers I ordered I don't plan to use any this time around.

Still after what Snuff did to correct his which was top notch and way better than what I had done, there's still a weak link somewhere.

This time around I'm leaving no room for doubt.

* New bushing kit from SATV

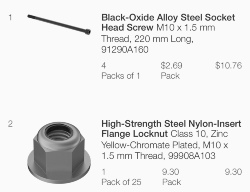

* New high strength flanged nut (with red lock tight)

* New 10.9 high strength bolt

* New chrome molly weld washers made just for an application like this

* Drilling a hole in the upper pivot tube like others have done.

* Lots of greese

Also want to note that I have some slop in the steering rack. I'm wondering if this play could be related to the issue I'm having with the upper A-arms. Joey posted up a great write up on fixing this. So I ordered the bushing and lock washer to fix this too.(like 20 bucks)

If I have problems in the near future after this fix, I'm taking it to SATV and let them tell me what the problem is!!!!

View attachment 105923