There have been multiple reports of U-Joints on the Talon falling apart. I have now fallen victim to the problem but luckily caught it in the shop before it broke and not out on the trail. Many speculations such as missing clips, bad joints, etc. Instead of replacing the driveline and throwing the bad parts into the trash, the OCD side of me just had to find out WHY!!!

Since all the joints were still intact, I started by dismantling the problem joint and found what is most likely the issue. Here is what I discovered...

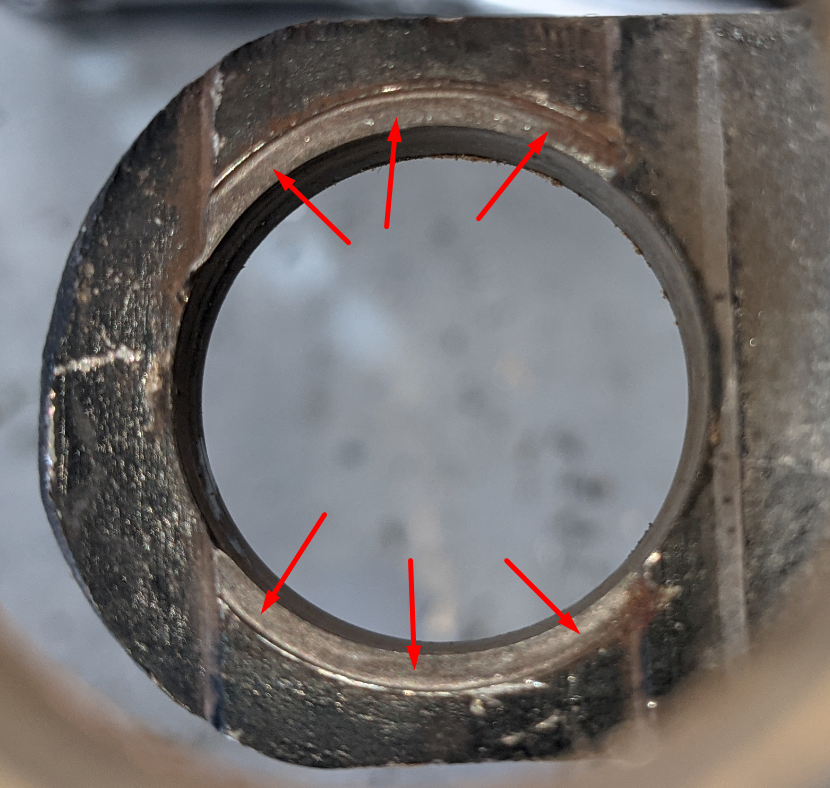

These grooves are .050" deep on each side of the yoke causing the joint to have .100" lateral movement.

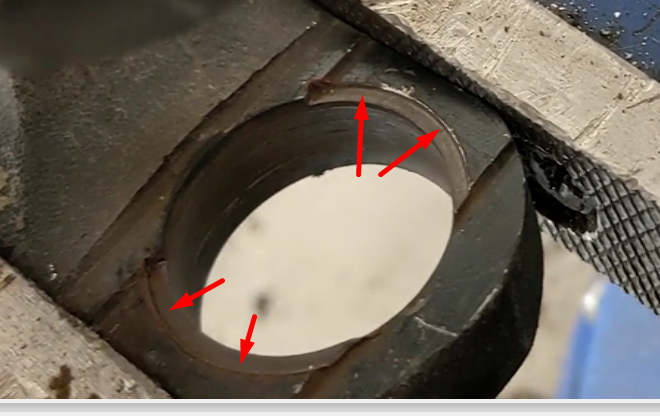

Although not as clear, this pic angle shows just how deep this groove became in a short period of time...

Since all the joints were still intact, I started by dismantling the problem joint and found what is most likely the issue. Here is what I discovered...

- Out of 8 cups, 2 of them are loose in the yoke. So loose that the cups came out by hand after the dirt was removed. (I have not dismantled the other joints yet and may not at this time).

- These 2 loose cups allowed the cross to move laterally about .100".

- After removing the 2 cups, measuring and inspected it, I realized there is absolutely nothing wrong with the joint itself. it is still tight and full of grease.

- Once I cleaned up the yoke, I found the problem and probably cause of failure.

- The series 1000 cups are .9375" and the effected bores in the yoke is ~.940. The bores do not appear to be worn, just too big for a proper interference fit. I noticed a similar "looseness" on another machine on one of the yokes although not as bad.

- The yoke is not spread, it is still 1.500" wide.

- The lateral movement of the cups have caused the harder clip material to wear out the yoke. This caused a grove and is where the lateral play is coming from (see pics below).

- Once that play become excessive enough, it either causes the cups to rotate enough for the clips to come out or enough "hammering" effect to break the clip.

- Once the clip comes off or breaks, the cup flies out and the damage continues.

- I am pretty certain that this is a tolerance issue and that the yokes do not start out that loose but some are loose enough from the factory to allow movement as the machine gets some miles on it. Once the movement starts, the damage is irreversible. Let it go long enough and the joint comes apart.

- New drivelines with as little as a few hundred miles have failed while some with 10,000 miles have not. This appears to be a manufacturing tolerance and/or QC issue.

- I have been checking my joints every few rides and just now discovered the movement, they were tight 2 or 3 rides ago. It seems it took about 3 rides (300 miles) for the movement to create the .050" wear so once the movement starts, it is not very long before the clip fails and the cup falls out.

- Although the series 1000 joints used on many SxS's are really made for steering shafts and not driveshafts, the factory joints are very high quality, sealed units. They have the good metal over rubber seals and should last 15,000 miles or more.

- Sealed, metal over rubber series 1000 joints are very hard to find so I put greaseable joints with crappy seals on another machine and after some research am now regretting that decision. I will be replacing those with sealed, higher quality joints in the near future.

- The drive shaft is 1.5" in diameter but there is no such thing as a 1.5" replacement yoke or driveline tubing. The only alternative is to go to 1.25" or 1.75" complete replacement shaft to see if the Spicer or Neapco yokes are any better quality.

- I will need to get a new driveline at this point. I can probably weld/grind the worn clip area and peen the bore smaller and tack weld the cups in on this one and "fix" it as a spare but not sure I can trust it for more than a short term backup unit.

- Regardless what I end up with, I will be tack welding ALL the cups in (even a brand new unit). I just do not trust these yokes!

These grooves are .050" deep on each side of the yoke causing the joint to have .100" lateral movement.

Although not as clear, this pic angle shows just how deep this groove became in a short period of time...