Hondasxs

Club Founder

Staff member

Lifetime Member

Supporting Member

So I have removed seats and all the rubber shields. I would like to do an ohm test but damned if I can find the ICUI would also recomend a good cleaning of the plunger. Be careful not to drop the pieces when you remove it.

i found the IACV it’s the PCM I can’t find now.Part 14 is the IACV. Is that what u looking for?

View attachment 184007

Found PCM, it was hidden pretty good. On the limited edition there is a storage box that has to be removed along with side panel. On the IACV valve the motor looks like it can turn both directions screwing into the piston which can move piston up or down to control speed. Ohm test on motor was within specs however my idle still revs up and down never leveling out. Found section of manual that describes how to reinstall valve, screwing piston all the way up shaft towards motor, and a 2 second test of motor out of throttle body. Still waiting for new connector kit to arrive from HondaSXS. More testing tomorrow.Oh. that's right under your butt!

PCM, PGM, ECM, ECU..... same box.

You need the gray connector.

Got my pig tail connector installed and did the 2 second ignition on, visual test to make sure iacv slide spun in both directions then stopped. Buttoned her up and all was good. I would like to thank the Honda SXS.COM for the making the connector available in store, the length of wire was perfect, the barrel crimps were easy to use and then solder, and finally the heat shrinks were great quality, filled with sealing glue, and thicker than cheesy HF grade.Found PCM, it was hidden pretty good. On the limited edition there is a storage box that has to be removed along with side panel. On the IACV valve the motor looks like it can turn both directions screwing into the piston which can move piston up or down to control speed. Ohm test on motor was within specs however my idle still revs up and down never leveling out. Found section of manual that describes how to reinstall valve, screwing piston all the way up shaft towards motor, and a 2 second test of motor out of throttle body. Still waiting for new connector kit to arrive from HondaSXS. More testing tomorrow.

Had the same issue. Low idle and stall out. Chased it down to the AICV. Took it out and cleaned it with CRC electric cleaner put it back in and it was idling at 2000 rpm cycling up to 2500 rpm. Went to my local Honda shop picked up a valve. When I took the old valve out and cycled the key while it was out of the machine and still plugged In. It did not move up and down. I plugged the new one in cycled the key and it did move up and down. Put it in hooked everything back up and…….. Runs Like New. Hope this helps anyone who needs it!!

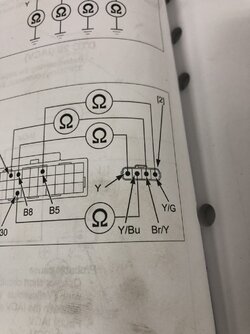

Getting the IACV code, with both connectors unplugged from the PCM, and the IACV, should I have continuity on the wire harness,Between brown /yellow, and yellow/green?The IACV valve on the Talon is difficult to get back in the hole correctly as well. It will go in on one of the little notches and hang up causing this type of sympto

If both connectors are removed from each component, you should NOT have continuity between the pins.Getting the IACV code, with both connectors unplugged from the PCM, and the IACV, should I have continuity on the wire harness,Between brown /yellow, and yellow/green?

(looking at the connector for the IACV, third and fourth hole left to right.)

View attachment 351258

That’s what I thought, just hoping it wasn’t that.If both connectors are removed from each component, you should NOT have continuity between the pins.

You should have continuity between BR/Y and pin B9(not sure, pic cuts off)

Continuity between Y/G and pin B5.

If you have continuity between BR/Y & Y/G with everything unplugged, you have a break in the harness somewhere and they have rubbed thru to each other.

Chances are it is some sort of rodent damage. Inspect for chewed wires and repair from there.That’s what I thought, just hoping it wasn’t that.

10-4, thanksChances are it is some sort of rodent damage. Inspect for chewed wires and repair from there.