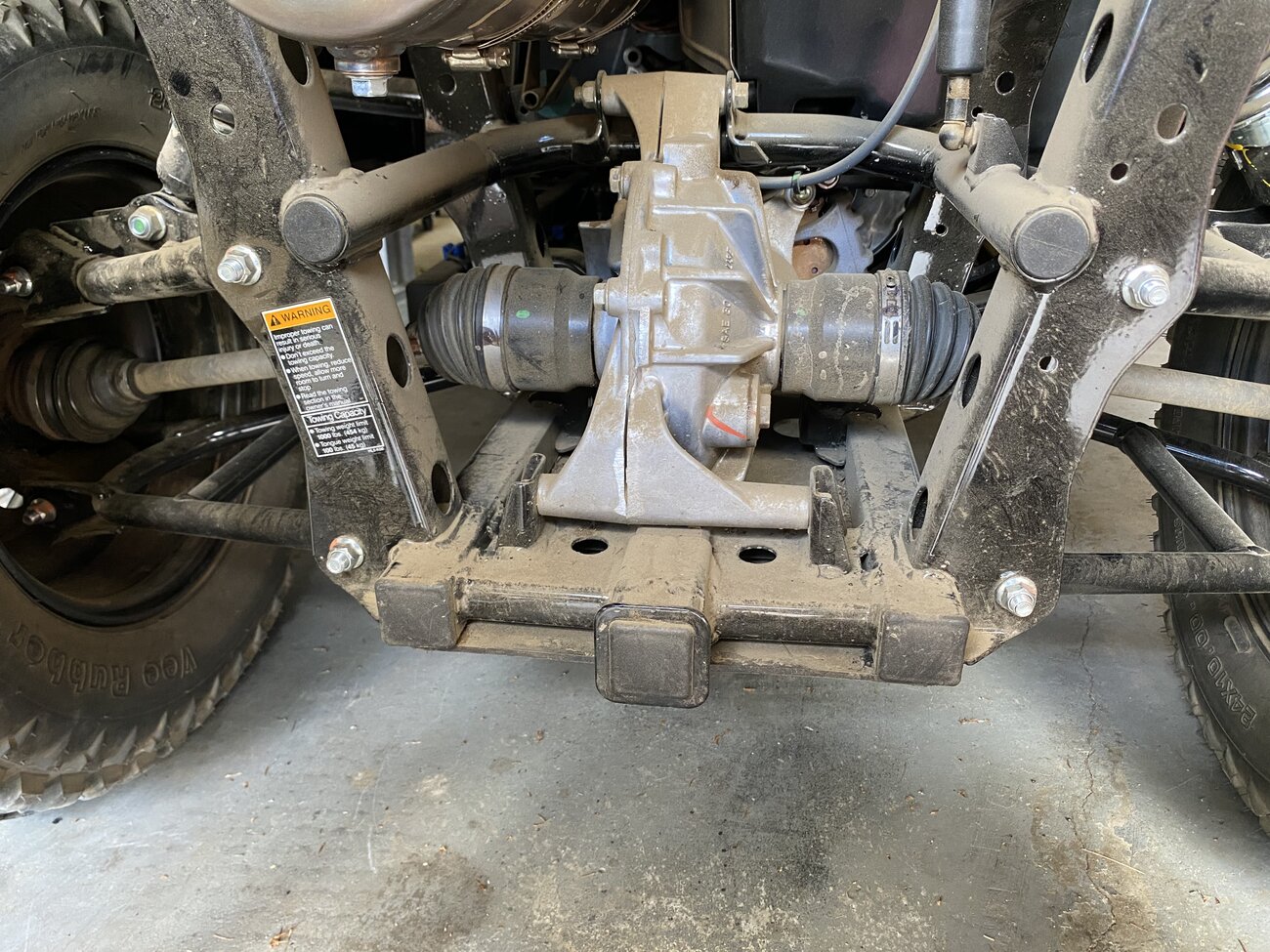

That's the same part number listed on my instructions for the hitch that I just bought last week. I found the lower holes to be very tight and the top holes were a little more off. I wanted to use M10 bolts instead of the included 3/8" bolts to keep everything metric. I was able to use M10 bolts for the lower holes, but not the top. I had to use the 3/8" bolts for the top and realized that they probably included the smaller bolts to make up for any tolerance issues.

I had to put one bolt in the bottom with the the nut just barely on and then had to put a lot of pressure on the mount to get the second bottom bolt to align while turning the bolt with a wrench to get it to screw into the hole. I had to keep using the wrench to get the bolt far enough through the hole to fasten the nut. I then alternately tightened each bolt from the back which pushed the mount away from the frame. This provided more wiggle room. I repeated this process for the top bolts. And, once I had all of the nuts on the bolts, I alternately tightened each nut a half turn or so at a time.

In retrospect, I wish I would have just widened all four of the holes a little before installation. And, although I currently have it installed this way, I will probably remove the top 3/8" bolts, drill larger top holes, and replace with M10 bolts.