So 4” and the SATV will still work with no

No issues just some refab work. If I had gone anymore than 4 " the windshield brackets would have been to long.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thank youThat looks great!

CumminsPusher

Just a Honda doing Honda things.

Lifetime Member

Supporting Member

Club Contributor

Looks great!Finally chopped it, wish I would've done it a long time ago. Had 4 inches taken out. Glad I didn't go more or getting the SATV window cut down would have been even more of a b**ch!

View attachment 98959 View attachment 98960

After my daughter and new son in law rolled my buggy... I have a sorta bent set of roll cage bars. I thought they may make a good start as an experiment to chop my top... I have a porta-band and a welder but no bender... what are the chances of taking out 6” or so?

FredD

FredD

CumminsPusher

Just a Honda doing Honda things.

Lifetime Member

Supporting Member

Club Contributor

6 is doable in the front and rear bars but the center would need some pretty good work where the center x brace that holds the seatbelts is. It would probably be easier to build that section itself at least. About 4 on the factory center b post is really max imo without adding a ton of work. You could pull extra inch on the front. Personally I suggest the front a posts 1 inch lower then the rest, it evacuates roof water well and keeps the sun out of your eyes nicelyAfter my daughter and new son in law rolled my buggy... I have a sorta bent set of roll cage bars. I thought they may make a good start as an experiment to chop my top... I have a porta-band and a welder but no bender... what are the chances of taking out 6” or so?

FredD

6 is doable in the front and rear bars but the center would need some pretty good work where the center x brace that holds the seatbelts is. It would probably be easier to build that section itself at least. About 4 on the factory center b post is really max imo without adding a ton of work. You could pull extra inch on the front. Personally I suggest the front a posts 1 inch lower then the rest, it evacuates roof water well and keeps the sun out of your eyes nicely

Sounds good... I will shoot for ~4” in front and ~3” at the back...

Thanks,

FredD

J

Looks good!! Arkhog 10

Sorry it's been a while guys, but I just wanted to give a update on some of my cage findings. The factory is not safe. I had built my own cage from scratch, this made it alot safer, but then on a bad rollover, the factory suports where the ROPS bolts to, gave out. The bars folded backwards anset the whole top come down a few inches. Just be careful guys these machines are heavy

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

advertisement

CumminsPusher

Just a Honda doing Honda things.

Lifetime Member

Supporting Member

Club Contributor

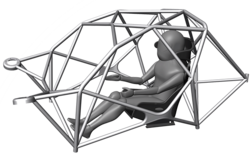

Looks good and tough as hell. I guess my only two concerns are it being so top heavy you might be using it constantly. I’m not a fan of upper weight. Also in a regular roll over not collapsing at all to cushion the impact. ROPS are actually designed to collapse. Now obviously a continuous roll down a long hill it wouldn’t take the abuse but it might try to stop a littleView attachment 101523View attachment 101524View attachment 101525View attachment 101526View attachment 101527View attachment 101528

Here is my final result from what I hope to be the last cage I have to build for a pioneer. Please let me know what y'all think before I get it Powdercaoted. Not opposed to any harsh criticism, maybee you all see something I didn't think about

Thanks guys

Sent from my iPhone using Tapatalk

I know there’s give and take for each situation. Just saying what I see. it looks great though and I like the front end braces.

Looks good and tough as hell. I guess my only two concerns are it being so top heavy you might be using it constantly. I’m not a fan of upper weight. Also in a regular roll over not collapsing at all to cushion the impact. ROPS are actually designed to collapse. Now obviously a continuous roll down a long hill it wouldn’t take the abuse but it might try to stop a little

I know there’s give and take for each situation. Just saying what I see. it looks great though and I like the front end braces.

I agree with the topheavy, but I rode a little in the feild beside my shop jerking back and forth. It doesn't seem to make much difference in that scenario, maybee on hills, but its so much lower hopefully the weight will even out. I also understand what your saying about the give, I'm just not a fan it personally thanks for the input

Sent from my iPhone using Tapatalk

I will let y'all know how the topheavy feel is after a few good rides though, hopefully it's bearable

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

CumminsPusher

Just a Honda doing Honda things.

Lifetime Member

Supporting Member

Club Contributor

I’ve been in two pretty good rolls In a P1k5.I agree with the topheavy, but I rode a little in the feild beside my shop jerking back and forth. It doesn't seem to make much difference in that scenario, maybee on hills, but its so much lower hopefully the weight will even out. I also understand what your saying about the give, I'm just not a fan it personally thanks for the input

Sent from my iPhone using Tapatalk

One was a double side roll with a chopped custom cage, it was very tippy and was gaining speed as it rolled. Was barely able to pull out of the roll with lots of throttle at the right time but it wanted to keep going as there was plenty of hill to do so. No damage to the cage though, landed on wheels then kept going thank god.

The other was a multiple endo with a chopped factory cage. The factory cage did fold but actually slowed the roll and wound up on wheels also.had it been 100% solid it would’ve went several more times.

On my endo I decided rather then build a cage I’d run factory hss cage and cut it down again, so bought all new pieces and cut it down. That’s the route I choose (with longer sleeves inside) because of the way it did fold. I felt that hit less then the hit from side roll with heavier wall steel.

I figure most times we roll it’ll be for short distance and I actually want the cage to collapse a bit to stop the inertia plus it’s lighter with a lot less tendency to roll. I can feel the difference in upper weight by just adding our cut down factory glass windshield. I have since taken all the lights,speaker bars and components from the top out and installed the lightest possible speaker mounts only, nothing else. We will continue to get into precarious situations and I’m just not a fan of the upper weight.

Like I said there is a fine line between lots of weight/strength and lighter/weaker. Cage may be strong enough to roll 20 times but maybe a weaker cage it only rolls a few and cushions the blow. Today’s cars that crumple are much safer then the 60’s that don’t. Different scenarios I know but just saying the other side that some don’t always see.

Last edited:

Smitty335

Well-Known Member

Lifetime Member

Supporting Member

I'm going to keep my rolling for the bed! HA!I’ve been in two pretty good rolls In a P1k5.

One was a double side roll with a chopped custom cage, it was very tippy and was gaining speed as it rolled. Was barely able to pull out of the roll with lots of throttle at the right time but it wanted to keep going as there was plenty of hill to do so. No damage to the cage though, landed on wheels then kept going thank god.

The other was a multiple endo with a chopped factory cage. The factory cage did fold but actually slowed the roll and wound up on wheels also.had it been 100% solid it would’ve went several more times.

On my endo I decided rather then build a cage I’d run factory hss cage and cut it down again, so bought all new pieces and cut it down. That’s the route I choose (with longer sleeves inside) because of the way it did fold. I felt that hit less then the hit from side roll with heavier wall steel.

I figure most times we roll it’ll be for short distance and I actually want the cage to collapse a bit to stop the inertia plus it’s lighter with a lot less tendency to roll. I can feel the difference in upper weight by just adding our cut down factory glass windshield. I have since taken all the lights,speaker bars and components from the top out and installed the lightest possible speaker mounts only, nothing else. We will continue to get into precarious situations and I’m just not a fan of the upper weight.

Like I said there is a fine line between lots of weight/strength and lighter/weaker. Cage may be strong enough to roll 20 times but maybe a weaker cage it only rolls a few and cushions the blow. Today’s cars that crumple are much safer then the 60’s that don’t. Different scenarios I know but just saying the other side that some don’t always see.

Montecresto

Montecresto el segundo

Lifetime Member

Supporting Member

Club Contributor

Yeah right lmao.....I'm going to keep my rolling for the bed! HA!

CumminsPusher

Just a Honda doing Honda things.

Lifetime Member

Supporting Member

Club Contributor

I’m going to try too but I know how things can go sometimes and I’ll always give things hell. Not going to drive around sticks and puddles like @ohanacreekI'm going to keep my rolling for the bed! HA!

advertisement

Similar threads

P

- Replies

- 3

- Views

- 363

P

P1000

Hard Top Height

- BlacktopBurner

- Pioneer 1000 Accessories and Modifications 2

- Replies

- 26

- Views

- 1K

D

- Replies

- 5

- Views

- 678

D

D

- Replies

- 4

- Views

- 1K