I'm probably going over the top on this, but...............

This is where I left off last weekend. Cutting the cover to free up the vertical wire channel, drilling the wire access hole and grinding off the corner of the negative terminal connector so I could tilt it up a little. The negative wire now clears the lip of the box and runs down the vertical shaft stress free.

Today I cut the Short lead supplied by Tera, soldered on a new copper connector and then sealed it with a couple of layers of shrink wrap.

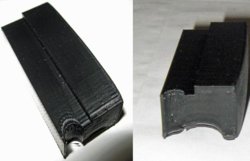

It even fits in the OEM terminal cover.

I bought two ten foot runs of solid copper stranded #4 so that I could relax and run to the front any way I wanted. Soldered copper terminal connectors and sealed them with shrink wrap.I should be able to close the box for the last time next weekend.

This is where I left off last weekend. Cutting the cover to free up the vertical wire channel, drilling the wire access hole and grinding off the corner of the negative terminal connector so I could tilt it up a little. The negative wire now clears the lip of the box and runs down the vertical shaft stress free.

Today I cut the Short lead supplied by Tera, soldered on a new copper connector and then sealed it with a couple of layers of shrink wrap.

It even fits in the OEM terminal cover.

I bought two ten foot runs of solid copper stranded #4 so that I could relax and run to the front any way I wanted. Soldered copper terminal connectors and sealed them with shrink wrap.I should be able to close the box for the last time next weekend.

Last edited: