D

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CID

Well-Known Member

Lifetime Member

Supporting Member

Lissen up, Peeps - When yer removing yer 'tool kit' to make sure there's a sparkplug socket innit (there is), be very careful. In Honda's diabolical way, they're out to get us. The easiest way to get the strap off, is to remove the inside end BUT as yer trying to get it out of the way, you'll falter and the damn thing will drop out of sight in the slot nearest you - DAMHIK

In the pic, the upper slot isn't big enough for the strap to fall through BUT that's not the easiest way to get it out, so you won't. The lower slot is more than big enough to swallow the strap whole and it will - DAMHIK And it will disappear completely out of sight behind the plastic 'thing' you can see 'down there' with a flashlight.

And it will disappear completely out of sight behind the plastic 'thing' you can see 'down there' with a flashlight.  Pondering my next step - I wondered iffn a magnet would retrieve the missing strap but my first attempt failed. Thinking about it some more, I wondered if a bent magnet would 'wrap around' said plastic thing 'down there' and I'll be damned if that didn't work.

Pondering my next step - I wondered iffn a magnet would retrieve the missing strap but my first attempt failed. Thinking about it some more, I wondered if a bent magnet would 'wrap around' said plastic thing 'down there' and I'll be damned if that didn't work.

So figure out a way to get the outside (bottom) undone first and THEN remove the strap. OR, hold on to that damn strap. In the left of this pic, you can see the aluminum duct tape that I used to block off the holes behind the seat. I'll be taping over the two slots at both ends of the rubber strap.

In the pic, the upper slot isn't big enough for the strap to fall through BUT that's not the easiest way to get it out, so you won't. The lower slot is more than big enough to swallow the strap whole and it will - DAMHIK

So figure out a way to get the outside (bottom) undone first and THEN remove the strap. OR, hold on to that damn strap. In the left of this pic, you can see the aluminum duct tape that I used to block off the holes behind the seat. I'll be taping over the two slots at both ends of the rubber strap.

G

CID

Well-Known Member

Lifetime Member

Supporting Member

Damn, I've had a burst of energy recently. I must be fearing the oncoming winter and 30* garage temps.

I had the dealer install my winch before I picked it up (new). This is where they put the plug for the cord, so I assumed that's where Honda wanted it.

But it invades the glovebox space and isn't 'ready to go'.

I developed envy over the 'real SxS guys' who had an In 'n Out winch switch on the dash, always ready to rumble. When I saw that the club store had the in dash switch and knew it would be ready to play, I bought one and installed it today. For the curious, being 'old school', toggle switches are my go-to, the top one operates the VM's and the bottom one controls the cig plug for the GPS.

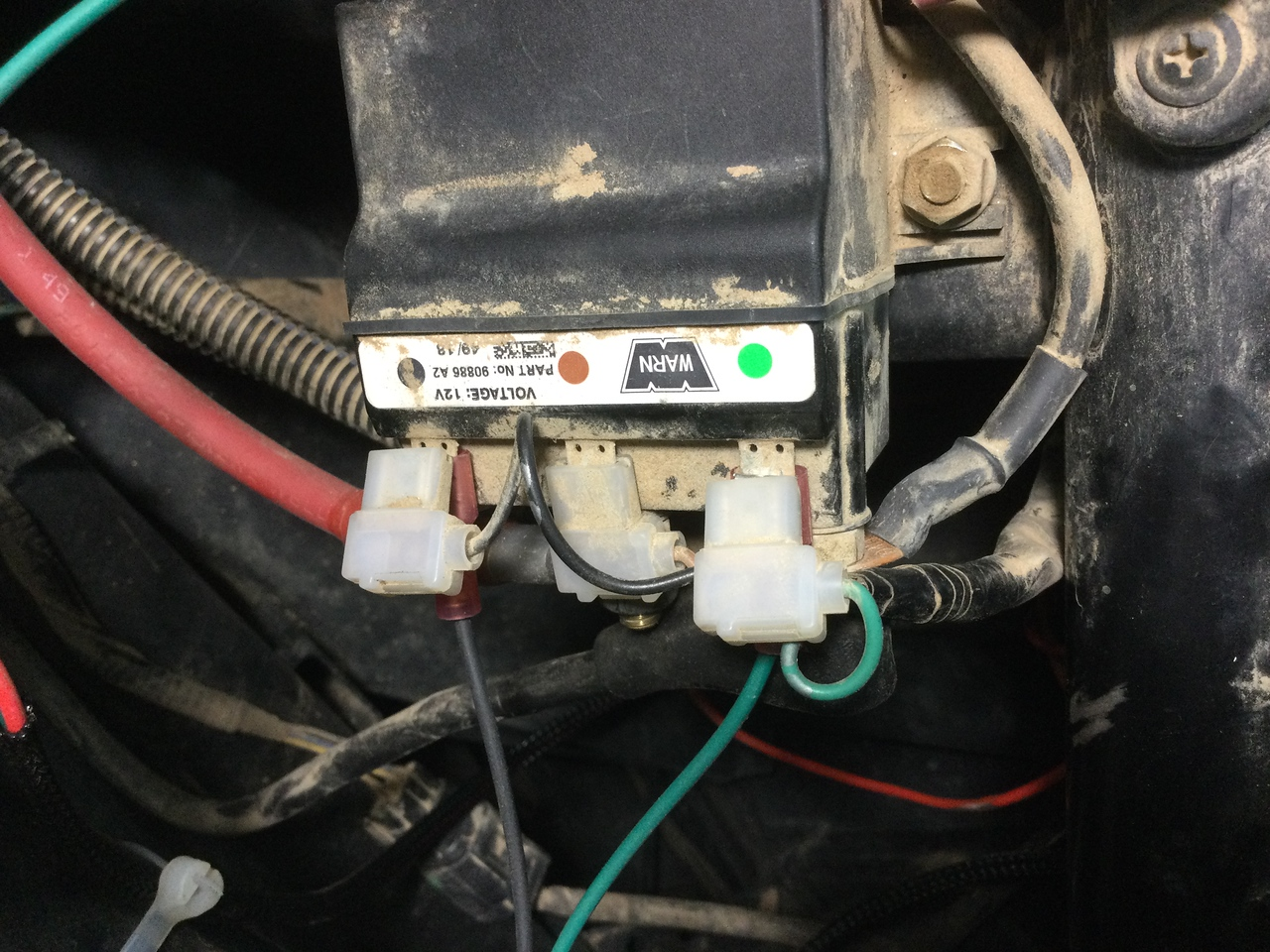

I got a little confused - the switch directions said the two contactor leads should both be considered Hot but it seemed that the colors matched the original wiring and I should connect the green and black wires to the green and black on the contactor. In my mind that meant I was connecting a Hot switch wire to a ground wire on the contactor. But I did it anyway and it worked properly. YAY The curly green and black wires are original and were on the bottom, the two new control wires are on the bottom, running off the bottom of the photo. The provided double tap connectors just worked out that way. The tan (or brown) wire in the middle isn't changed. Note the 3 colored dots on the contactor denoting where each (original) wire belongs. This remains true with the in-dash switch, green to green, black to black. Note that both the center brown and right green aren't fully plugged in, pay attention when you do this. I went back and used Channel Locks to get them to seat completely.

While I had the hood cowl off, I wanted to add a dual USB port, also from the club store, to run the tablet. Since USBs have a parasitic drain, it's on a switched circuit, unlike the cig plug right next to it. The cig plug is controlled by a toggle switch (mentioned above) so I can turn it off when hosing down the interior. I didn't want it switched by the ignition since it runs the GPS, which I want to stay on. Placement is in front of the passenger's left knee. There's ample room and I'll rarely have a passenger - measure twice, cut once. The cig plug is covered in the first post of this thread.

The iPad struggled with a sharp close up.

I had the dealer install my winch before I picked it up (new). This is where they put the plug for the cord, so I assumed that's where Honda wanted it.

But it invades the glovebox space and isn't 'ready to go'.

I developed envy over the 'real SxS guys' who had an In 'n Out winch switch on the dash, always ready to rumble. When I saw that the club store had the in dash switch and knew it would be ready to play, I bought one and installed it today. For the curious, being 'old school', toggle switches are my go-to, the top one operates the VM's and the bottom one controls the cig plug for the GPS.

I got a little confused - the switch directions said the two contactor leads should both be considered Hot but it seemed that the colors matched the original wiring and I should connect the green and black wires to the green and black on the contactor. In my mind that meant I was connecting a Hot switch wire to a ground wire on the contactor. But I did it anyway and it worked properly. YAY The curly green and black wires are original and were on the bottom, the two new control wires are on the bottom, running off the bottom of the photo. The provided double tap connectors just worked out that way. The tan (or brown) wire in the middle isn't changed. Note the 3 colored dots on the contactor denoting where each (original) wire belongs. This remains true with the in-dash switch, green to green, black to black. Note that both the center brown and right green aren't fully plugged in, pay attention when you do this. I went back and used Channel Locks to get them to seat completely.

While I had the hood cowl off, I wanted to add a dual USB port, also from the club store, to run the tablet. Since USBs have a parasitic drain, it's on a switched circuit, unlike the cig plug right next to it. The cig plug is controlled by a toggle switch (mentioned above) so I can turn it off when hosing down the interior. I didn't want it switched by the ignition since it runs the GPS, which I want to stay on. Placement is in front of the passenger's left knee. There's ample room and I'll rarely have a passenger - measure twice, cut once. The cig plug is covered in the first post of this thread.

The iPad struggled with a sharp close up.

Last edited:

Huntndogs

Well-Known Member

Supporting Member

CID

Well-Known Member

Lifetime Member

Supporting Member

ETA: Scroll down to post #79 to see how HondaTech recommends doing this.

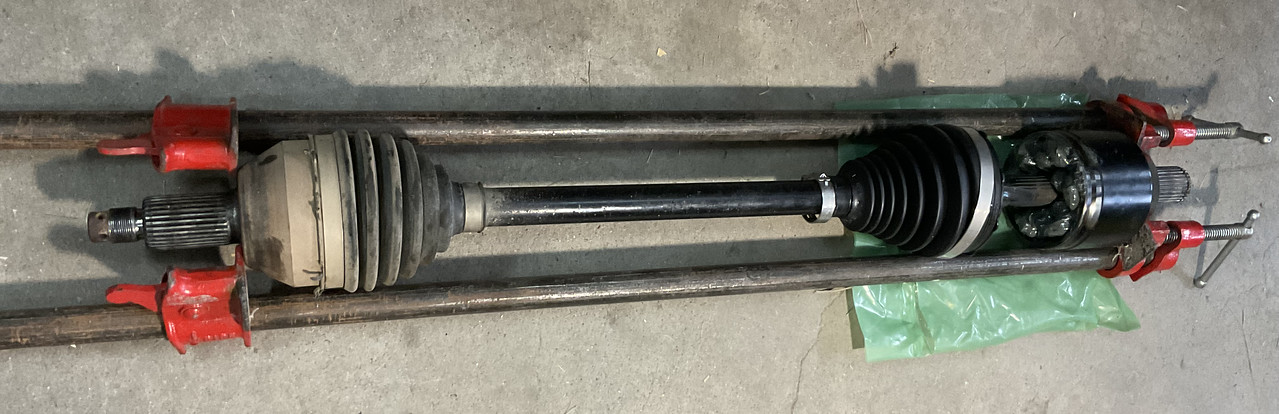

My left rear CV boot sprung a leak and it was clicking pretty bad anyway, time to learn how to replace a CV joint and its boot. Russel's video covers about everything I needed to know but I wasn't sure about getting the axle into the CV joint and KNOWING it was all the way in. Once you fill the thing with grease, you can't see doo doo, and I didn't want it falling apart, my next ride will be in Utah.

(Over) thinking about it, this idear rose to the surface. It worked well, both CV joints are stifff enough that they didn't flop when I was snugging the clamps down and it was really slow motion, so I could see what was going on. And, more important than seeing, was hearing - I heard the c-clip snap into place when it was in far enough (the one on the axle, not the one going into the differential).

The service manual says to set the axle length to 31.5" but my c-clip didn't click until ~30-3/4". If I had gone by Honda's dimension, the c-clip wouldn't be in place (past the inner end of the splines), bad juju. 30-3/4" is pretty much the 'full compression' length of the total rear axle assembly. Note that while I completely bottomed the axle into the CV joint, I did NOT reef down on the clamps, I just gently snugged it in to make sure the circlip cleared the splines. Hitting bottom was only ~1/8" past the clicking of the circlip.

(past the inner end of the splines), bad juju. 30-3/4" is pretty much the 'full compression' length of the total rear axle assembly. Note that while I completely bottomed the axle into the CV joint, I did NOT reef down on the clamps, I just gently snugged it in to make sure the circlip cleared the splines. Hitting bottom was only ~1/8" past the clicking of the circlip.

I bought the wrong clamp pinch pliers so I'll have the dealer crimp them for me. Hopefully they won't tell me 'we'll have 'em done in 3 weeks'.

DO NOT FORGET to put the small clamp and boot on the axle first.

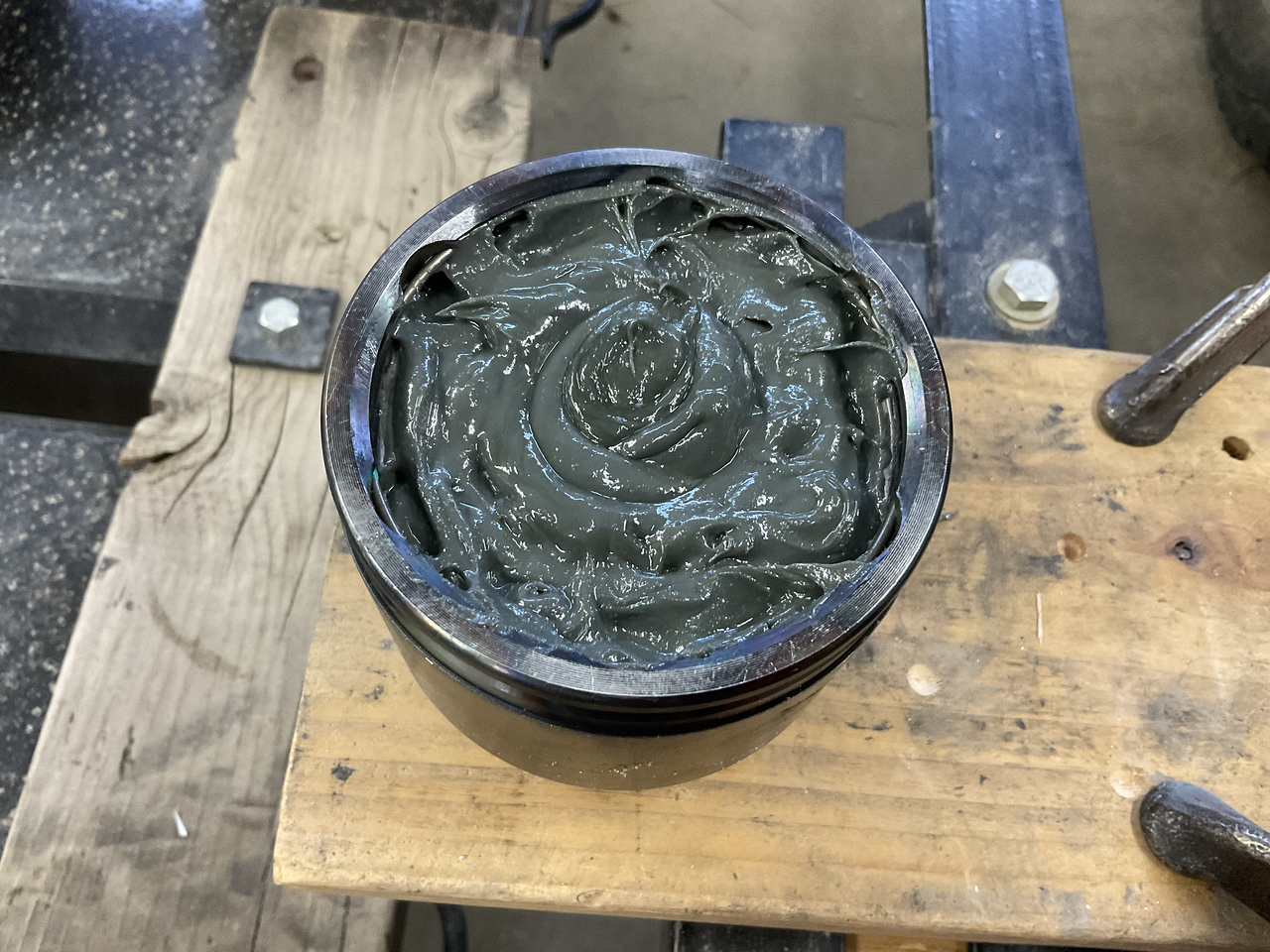

I drilled a 1-1/4" hole in a 2x6 and clamped it to the trailer, pulled up a milk crate to sit on and commenced to stuffing grease in everywhere. The exposed CV stub is where the seal seats and I didn't want to clamp it in the vise (soft jaws would solve that). You won't be moving the race around with your fingers, it's tight. I used the axle to work it around. This is where I should have worked the race to the top and filled the area under the race first but I didn't know that 'then'.

Spec calls for 2-1/2 of the 3 bags of grease, and that completely fills the CV. I've pulled the race up close to the top here using the axle to help me lever it up.

Overall view -

What's in there once the bearing race is pushed fully into the CV joint and all the grease gets displaced. I had to reset the bar clamps once because I ran out of threads (so the one inch compression you see here is misleading).

The more grease you can get behind the race before pulling the axle in, the more grease that gets forced into and through the race, a good thing.

Russel says a few taps with a long screwdriver will drive the CV joint out of the differential. I had to hit that damn thing with a 2 lb. sledge like I was trying to kill Godzilla. I also rotated it 'a bit' a few times looking for the sweet spot (circlip lined up). No, you can't see the circlip but, since you're hitting it from one side, you're putting pressure on the same 'piece' of the circlip, so I rotated the axle between hits, hoping that would help. YMMV

He also mentions to NOT yank on the axle to get the assembly out of the diff - he's right. I watched Adrenalin Junkie remove a Polaris axle and he just yanked the whole thing out but, on my Talon, the axle pulled out of the CV, the CV did NOT pull out of the diff.

I watched Adrenalin Junkie remove a Polaris axle and he just yanked the whole thing out but, on my Talon, the axle pulled out of the CV, the CV did NOT pull out of the diff.  Now I had to cut the boot around the circumference to get the axle out of my way and THEN beat the CV out of the diff.

Now I had to cut the boot around the circumference to get the axle out of my way and THEN beat the CV out of the diff.

At 6:14 he shows the CV joint with the balls and race at the bottom of the 'bucket'. I put the axle in and worked it around to get the race 'up' so I could grease it - I had NO IDEA how much grease would be used so I started 'on top' (toward me). But now I know that you're going to FILL the CV with grease. Next time, I'll move the race to the top (outer) and fill the void UNDER the race first. Doing this will force grease into the underside of the race (when you pull the axle into the CV, the race will 'sink' to the bottom, which is now full of grease), something I wasn't able to do very easily - I tried but I had greased the top in solid except for the axle hole.

Russel removed the lower shock bolt so he could get the trailing arm out of the way. I had removed everything else and then removed the nut from the lower shock mount when I noticed that might not be necessary - I have everything apart and the shock is still connected to the trailing arm - but it's not back together yet either. ETA: you don't have to disconnect the shock from the trailing arm, there's way more than enough clearance leaving it connected.

Part numbers from the video -

42230-HL8-A02 Rear inner boot and 3 grease packets.

422220-HL6-A01 Rear inner CV joint

Russel's video including the CV and boot part numbers -

Showing that the shock can stay connected to the trailing arm. I had already removed the nut before I realized it didn't need to come apart.

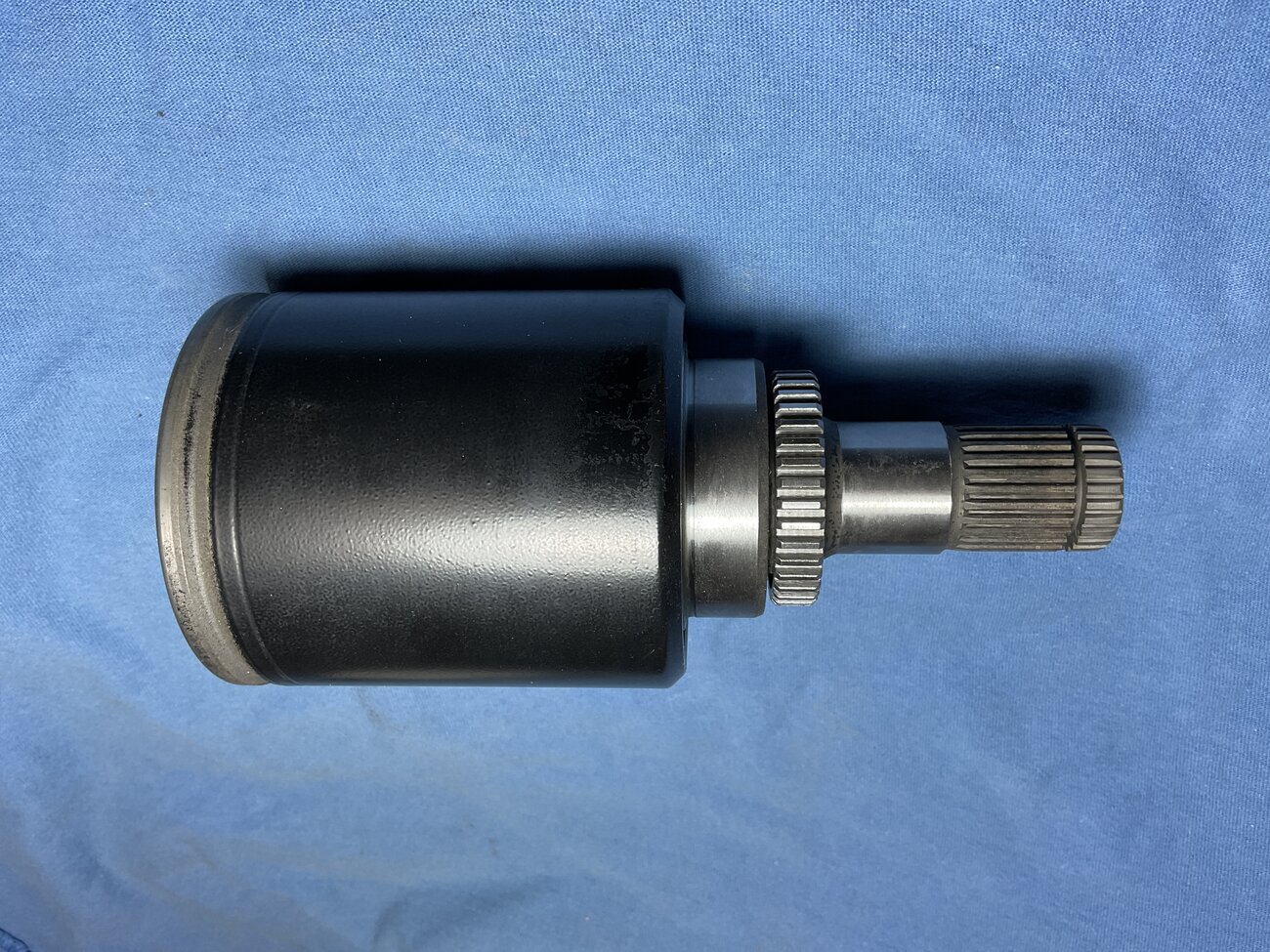

Front CV, side view showing the wheel speed sensor gear -

Rear CV -

My left rear CV boot sprung a leak and it was clicking pretty bad anyway, time to learn how to replace a CV joint and its boot. Russel's video covers about everything I needed to know but I wasn't sure about getting the axle into the CV joint and KNOWING it was all the way in. Once you fill the thing with grease, you can't see doo doo, and I didn't want it falling apart, my next ride will be in Utah.

(Over) thinking about it, this idear rose to the surface. It worked well, both CV joints are stifff enough that they didn't flop when I was snugging the clamps down and it was really slow motion, so I could see what was going on. And, more important than seeing, was hearing - I heard the c-clip snap into place when it was in far enough (the one on the axle, not the one going into the differential).

The service manual says to set the axle length to 31.5" but my c-clip didn't click until ~30-3/4". If I had gone by Honda's dimension, the c-clip wouldn't be in place

I bought the wrong clamp pinch pliers so I'll have the dealer crimp them for me. Hopefully they won't tell me 'we'll have 'em done in 3 weeks'.

DO NOT FORGET to put the small clamp and boot on the axle first.

I drilled a 1-1/4" hole in a 2x6 and clamped it to the trailer, pulled up a milk crate to sit on and commenced to stuffing grease in everywhere. The exposed CV stub is where the seal seats and I didn't want to clamp it in the vise (soft jaws would solve that). You won't be moving the race around with your fingers, it's tight. I used the axle to work it around. This is where I should have worked the race to the top and filled the area under the race first but I didn't know that 'then'.

Spec calls for 2-1/2 of the 3 bags of grease, and that completely fills the CV. I've pulled the race up close to the top here using the axle to help me lever it up.

Overall view -

What's in there once the bearing race is pushed fully into the CV joint and all the grease gets displaced. I had to reset the bar clamps once because I ran out of threads (so the one inch compression you see here is misleading).

The more grease you can get behind the race before pulling the axle in, the more grease that gets forced into and through the race, a good thing.

Russel says a few taps with a long screwdriver will drive the CV joint out of the differential. I had to hit that damn thing with a 2 lb. sledge like I was trying to kill Godzilla. I also rotated it 'a bit' a few times looking for the sweet spot (circlip lined up). No, you can't see the circlip but, since you're hitting it from one side, you're putting pressure on the same 'piece' of the circlip, so I rotated the axle between hits, hoping that would help. YMMV

He also mentions to NOT yank on the axle to get the assembly out of the diff - he's right.

At 6:14 he shows the CV joint with the balls and race at the bottom of the 'bucket'. I put the axle in and worked it around to get the race 'up' so I could grease it - I had NO IDEA how much grease would be used so I started 'on top' (toward me). But now I know that you're going to FILL the CV with grease. Next time, I'll move the race to the top (outer) and fill the void UNDER the race first. Doing this will force grease into the underside of the race (when you pull the axle into the CV, the race will 'sink' to the bottom, which is now full of grease), something I wasn't able to do very easily - I tried but I had greased the top in solid except for the axle hole.

Russel removed the lower shock bolt so he could get the trailing arm out of the way. I had removed everything else and then removed the nut from the lower shock mount when I noticed that might not be necessary - I have everything apart and the shock is still connected to the trailing arm - but it's not back together yet either. ETA: you don't have to disconnect the shock from the trailing arm, there's way more than enough clearance leaving it connected.

Part numbers from the video -

42230-HL8-A02 Rear inner boot and 3 grease packets.

422220-HL6-A01 Rear inner CV joint

Russel's video including the CV and boot part numbers -

Showing that the shock can stay connected to the trailing arm. I had already removed the nut before I realized it didn't need to come apart.

Front CV, side view showing the wheel speed sensor gear -

Rear CV -

Last edited:

SLOWPOKE693

Well-Known Member

Supporting Member

P1K5Dave

Well-Known Member

Lifetime Member

Club Contributor

He also mentions to NOT yank on the axle to get the assembly out of the diff - he's right.

Hmm, I always do that and have never had a problem but I can see how it would suck if it went wrong.

When my RR axle was shot, I couldn't just yank it out because it was broken inside - if I pulled it I was just stretching the boot. I was able to get it out by inserting a pry bar at the diff and popping it out that way.

Is that how you're supposed to do it?

P1K5Dave

Well-Known Member

Lifetime Member

Club Contributor

CID

Well-Known Member

Lifetime Member

Supporting Member

The service manual says to get a long screwdriver in behind the CV and hammer it out, like Russel shows in the video (well, he points out what to do but doesn't show video). The CV joint is solid steel, you aren't going to hurt it. In my case, it was getting replaced anyway. I was afraid to use a pry bar against the diff but, done gently, might work and it would be a straighter force than hitting it at an angle with a screwdriver. There's no straight shot at the CV, the diff is right there, so are rear frame tubes. Some time ago I bought a long screwdriver from HF with a 1/2" shank and ~20* bend at the blade end. It worked just right.Hmm, I always do that and have never had a problem but I can see how it would suck if it went wrong.

When my RR axle was shot, I couldn't just yank it out because it was broken inside - if I pulled it I was just stretching the boot. I was able to get it out by inserting a pry bar at the diff and popping it out that way.

Is that how you're supposed to do it?

Like the big one here - (listed under pry bars)

advertisement

SLOWPOKE693

Well-Known Member

Supporting Member

Looking good @SLOWPOKE693

When's your season start again?

March 2023. We bought a house back in February so I decided to take this season off to get settled there. We are settled now and I'm itching to get back to racing.

SLOWPOKE693

Well-Known Member

Supporting Member

The service manual says to get a long screwdriver in behind the CV and hammer it out, like Russel shows in the video (well, he points out what to do but doesn't show video). The CV joint is solid steel, you aren't going to hurt it. In my case, it was getting replaced anyway. I was afraid to use a pry bar against the diff but, done gently, might work and it would be a straighter force than hitting it at an angle with a screwdriver. There's no straight shot at the CV, the diff is right there, so are rear frame tubes. Some time ago I bought a long screwdriver from HF with a 1/2" shank and ~20* bend at the blade end. It worked just right.

Like the big one here - (listed under pry bars)

View attachment 358940

Did you catch the lip on the axle seal doing it like that?

CID

Well-Known Member

Lifetime Member

Supporting Member

I hope not, this is my first time and what the service manual calls for. Once the c-clip is past the inside end of the splines, removing the CV the rest of the way is a straight pull outward. The bent prybar I used hit about the middle of the taper on the CV joint, nowhere near the seal. The only way I can see to damage the axle seal would be by prying carelessly between the CV and the diff seal. I wasn't anywhere near the seal.Did you catch the lip on the axle seal doing it like that?

Any tips or suggestions for the next guy?

Last edited:

G

SLOWPOKE693

Well-Known Member

Supporting Member

Any tips or suggestions for the next guy?

Don't use a big screw driver and hit the seal like I usually do.....

SLOWPOKE693

Well-Known Member

Supporting Member

Speaking of axle seals..... I tried ordering new F&R axle seals from Babbitts online and the fronts are not available. Is this a thing or is everyone just out of those seals? Luckily I didn't need the fronts and just wanted spares, but still....

H

HondaTech

Guest

My left rear CV boot sprung a leak and it was clicking pretty bad anyway, time to learn how to replace a CV joint and its boot. Russel's video covers about everything I needed to know but I wasn't sure about getting the axle into the CV joint and KNOWING it was all the way in. Once you fill the thing with grease, you can't see doo doo, and I didn't want it falling apart, my next ride will be in Utah.

(Over) thinking about it, this idear rose to the surface. It worked well, both CV joints are stifff enough that they didn't flop when I was snugging the clamps down and it was really slow motion, so I could see what was going on. And, more important than seeing, was hearing - I heard the c-clip snap into place when it was in far enough (the one on the axle, not the one going into the differential).

The service manual says to set the axle length to 31.5" but my c-clip didn't click until ~30-3/4". If I had gone by Honda's dimension, the c-clip wouldn't be in place(past the inner end of the splines), bad juju. 30-3/4" is pretty much the 'full compression' length of the total rear axle assembly. Note that while I completely bottomed the axle into the CV joint, I did NOT reef down on the clamps, I just gently snugged it in to make sure the circlip cleared the splines. Hitting bottom was only ~1/8" past the clicking of the circlip.

I bought the wrong clamp pinch pliers so I'll have the dealer crimp them for me. Hopefully they won't tell me 'we'll have 'em done in 3 weeks'.

DO NOT FORGET to put the small clamp and boot on the axle first.

I drilled a 1-1/4" hole in a 2x6 and clamped it to the trailer, pulled up a milk crate to sit on and commenced to stuffing grease in everywhere. The exposed CV stub is where the seal seats and I didn't want to clamp it in the vise (soft jaws would solve that). You won't be moving the race around with your fingers, it's tight. I used the axle to work it around. This is where I should have worked the race to the top and filled the area under the race first but I didn't know that 'then'.

View attachment 358951

Spec calls for 2-1/2 of the 3 bags of grease, and that completely fills the CV. I've pulled the race up close to the top here using the axle to help me lever it up.

View attachment 358953

Overall view -

View attachment 358926

What's in there once the bearing race is pushed fully into the CV joint and all the grease gets displaced. I had to reset the bar clamps once because I ran out of threads (so the one inch compression you see here is misleading).

View attachment 358927

The more grease you can get behind the race before pulling the axle in, the more grease that gets forced into and through the race, a good thing.

View attachment 358928

Russel says a few taps with a long screwdriver will drive the CV joint out of the differential. I had to hit that damn thing with a 2 lb. sledge like I was trying to kill Godzilla. I also rotated it 'a bit' a few times looking for the sweet spot (circlip lined up). No, you can't see the circlip but, since you're hitting it from one side, you're putting pressure on the same 'piece' of the circlip, so I rotated the axle between hits, hoping that would help. YMMV

He also mentions to NOT yank on the axle to get the assembly out of the diff - he's right.I watched Adrenalin Junkie remove a Polaris axle and he just yanked the whole thing out but, on my Talon, the axle pulled out of the CV, the CV did NOT pull out of the diff.

Now I had to cut the boot around the circumference to get the axle out of my way and THEN beat the CV out of the diff.

At 6:14 he shows the CV joint with the balls and race at the bottom of the 'bucket'. I put the axle in and worked it around to get the race 'up' so I could grease it - I had NO IDEA how much grease would be used so I started 'on top' (toward me). But now I know that you're going to FILL the CV with grease. Next time, I'll move the race to the top (outer) and fill the void UNDER the race first. Doing this will force grease into the underside of the race (when you pull the axle into the CV, the race will 'sink' to the bottom, which is now full of grease), something I wasn't able to do very easily - I tried but I had greased the top in solid except for the axle hole.

Russel removed the lower shock bolt so he could get the trailing arm out of the way. I had removed everything else and then removed the nut from the lower shock mount when I noticed that might not be necessary - I have everything apart and the shock is still connected to the trailing arm - but it's not back together yet either.

Part numbers from the video -

42230-HL8-A02 Rear inner boot and 3 grease packets.

422220-HL6-A01 Rear inner CV joint

Russel's video including the CV and boot part numbers -

Wow, you kinds made that way more complicated then it needed to be.

CID

Well-Known Member

Lifetime Member

Supporting Member

It was my first time.Wow, you kinds made that way more complicated then it needed to be.

How do you get the axle into the CV and know it's in far enough to clear the circlip?

H

HondaTech

Guest

It was my first time.Next time I'll probably just thump it on the floor til it seats.

How do you get the axle into the CV and know it's in far enough to clear the circlip?

I take the balls out of the cage, put the clip on the axle and then tap the inner bearing race onto the shaft.

Grease the balls individually, smear the cage with grease, fill the cup with grease. Push the whole thing into the cup and snap the large ring into the cup.

CID

Well-Known Member

Lifetime Member

Supporting Member

It never occurred to me to disassemble the CV itself, thanks for the tip.I take the balls out of the cage, put the clip on the axle and then tap the inner bearing race onto the shaft.

Grease the balls individually, smear the cage with grease, fill the cup with grease. Push the whole thing into the cup and snap the large ring into the cup.

Last edited:

advertisement

Similar threads

C

- Replies

- 26

- Views

- 3K

C

- Replies

- 6

- Views

- 497

- Replies

- 25

- Views

- 2K

- Replies

- 28

- Views

- 2K

- Replies

- 16

- Views

- 2K