Another 'later in the life of a Talon' post. Mine was at 10,900 miles.

My preferred riding is in the desert SW but that's extremely seasonal, a few weeks in the sping and another few weeks in the fall. Other than that, it's just too damn hot for humans.

Living in Denver, my backyard is the Rocky Mountains, and there are a lot of water crossings there. I never considered it a problem since 'most of the time' it's dry. Anytime I have to cross a stream, there's ample time for things to dry out, unlike a wet/humid climate. So I ignored water problems until -

On my recent Moab trip, I developed a soft brake pedal but only for one pump, at which time the pedal was solid. I mentioned the soft pedal to

@PaulF - first guess, air in system and he had noticed that my i4wd didn't seem to be working properly (which relies on proper braking response to stop the spinning wheel), something I can't see from the driver's seat. But when I told him that one pump would return it to normal, he immediately said - "Bad wheel bearing." Huh? "Yep, the bad bearing is allowing the rotor to wiggle which pushes the pads back into the caliper, the one soft pump pushes them back out and things are normal for another few revolutions.

When I got home, jacked 'er up and, sure enough, the LR is toast. This is the story of that cluster F.

Having forgotten how it came apart when I replaced the LR inner CV joint, I was confused when the rotor wouldn't pull off after removing the axle nut. A quick trip to YouTube University and, sure enough, it should slide right off. Well, it didn't.

Out with the pry bar, and no matter how hard I leaned on it, no movement. So I found a way to use the bar like a slide hammer, still no love but at least I

knew that damn rotor and hub should slide off. So I persisted, after 'forever' I looked behind the hub and saw a ~.030" gap where I had wiped the grease off (I had pulled the hub off of the axle, so I could see behind the bearing).

There's a little more info in this thread, where I asked the initial question -

@#$%& Murphy's Law. :mad: On my recent Moab trip, I developed a soft brake pedal but only for one pump, at which time the pedal was solid. I mentioned the soft pedal to @PaulF , first guess, air in system and he had noticed that my i4wd didn't seem to be working properly, something I can't see...

hondasxs.com

Now that I had movement, I just kept banging away on the pry bar. I got it about halfway out of the bearing, noticing that the machined hub surface was badly galled and then ... it popped right off ... sometin' ain't rite here ...

That's supposed to be a smooth, shiny surface.

I ride in the desert (first choice) and high country when the desert gets too damn hot; not 'much' water but some and I don't mind riding through it. Apparently 'some' is too much.

It's not supposed to look like this, the bearing is one piece.

You can see where I was slide hammering the pry bar. Note the notch at the bottom, that's a drain, be sure to line up the circlip with it. Note, also, that there's no indication of water incursion, the damage is between the rotor hub and the ID of the bearing.

This bolt stopped me, it's tapered like a ball joint, I need to find out how it comes apart (details below). So instead of heading back to Utah, I'll be waiting for hubs and rotors (it's apart and the rotors have seen better days after 10,900 miles).

I have to thank

@hondabob for the following information. He mentioned the Harbor Fright ball joint separator and that it had to be widened to work for this application. Fortunately, I had bought it earlier, so all I had to do was grind it to fit. Item 99849.

Pay attention - this thing pushes against the threaded end of the ball joint - On the first one, I put the castle nut on backwards to protect the threads BUT it didn't. So now I have a nut on backwards that won't come off because the ball joint stud is spinning, now WTF? There's no access on the back. The neighbor and I were able to push the rubber boot back, grab the taper on the ball joint with a narrow Vice Grip and get that damn nut off with a Channel Lock. On the second one, I protected the threaded end of the ball joint with a piece of steel between the separator and the ball joint threads. Grrrrr

My bench grinder uses a 1" wide wheel, so I started by gently pushing the open jaw of the separator into the wheel, moving a bit side to side so it wouldn't bind. Then I used a 4-1/2" angle grinder to grind to fit by eye, close enough for a JAH.

This is the shoulder you have to straddle -

And it's 35.92 mm wide if you want to pre grind you separator -

Next step was to grind a piece of 3/8" thick steel to push against in the press to get the bearing out. I cut it 2-1/2" long and rounded the corners to fit. You can see where the largest socket I had fit the bearing, not important for removing a bad bearing but you don't want to push against the balls on a good bearing, bad juju.

@Dankathy did this without a press, and I don't think he'll ever be right again.

When the bearing released, it went off like a rifle shot, with two of us hanging on the handle of a 20 ton jack. A 20 ton HF press is $250 now and, after having done this, is well worth the cost. And it gives you an excuse to buy tools, which are an investment, not an expense.

I made another 3/8" thick piece to push the bearing back in, making sure to straddle as much of the bearing as possible. It's 2-3/4" long with rounded corners to fit. Yes, we removed the circlip first.

This is the hub and rotor, I decided to replace both, the hubs were junk and the rotors had seen better days at 10,900 miles.

Mmmmmm, pritty and new.

Do NOT FORGET to give the hubs a fresh coat of grease or you could end up right back here.

New hubs come with studs. Hub part number is 42615-HL6-A00. Rotor part number is 43251-HL6-A01.

The bearings are YUGE - 2-7/8" x 1-7/16" (73 x 38 mm).

Dan suggested that we pull the hubs twice a year and grease between the hub and bearing. Methinks that be a good idear, especially iffn you live in a wetter environment than I do (Dan is also a desert rat). Don't be afraid to give your rattle gun an extra braaaaap to get the axle nut good and tight, maybe that's all it will take to keep this from happening again ... maybe.

The axle shaft is cross drilled for the cotter key, making it easier to line up with the castle nut. Be sure to give the splines a fresh coat of grease.

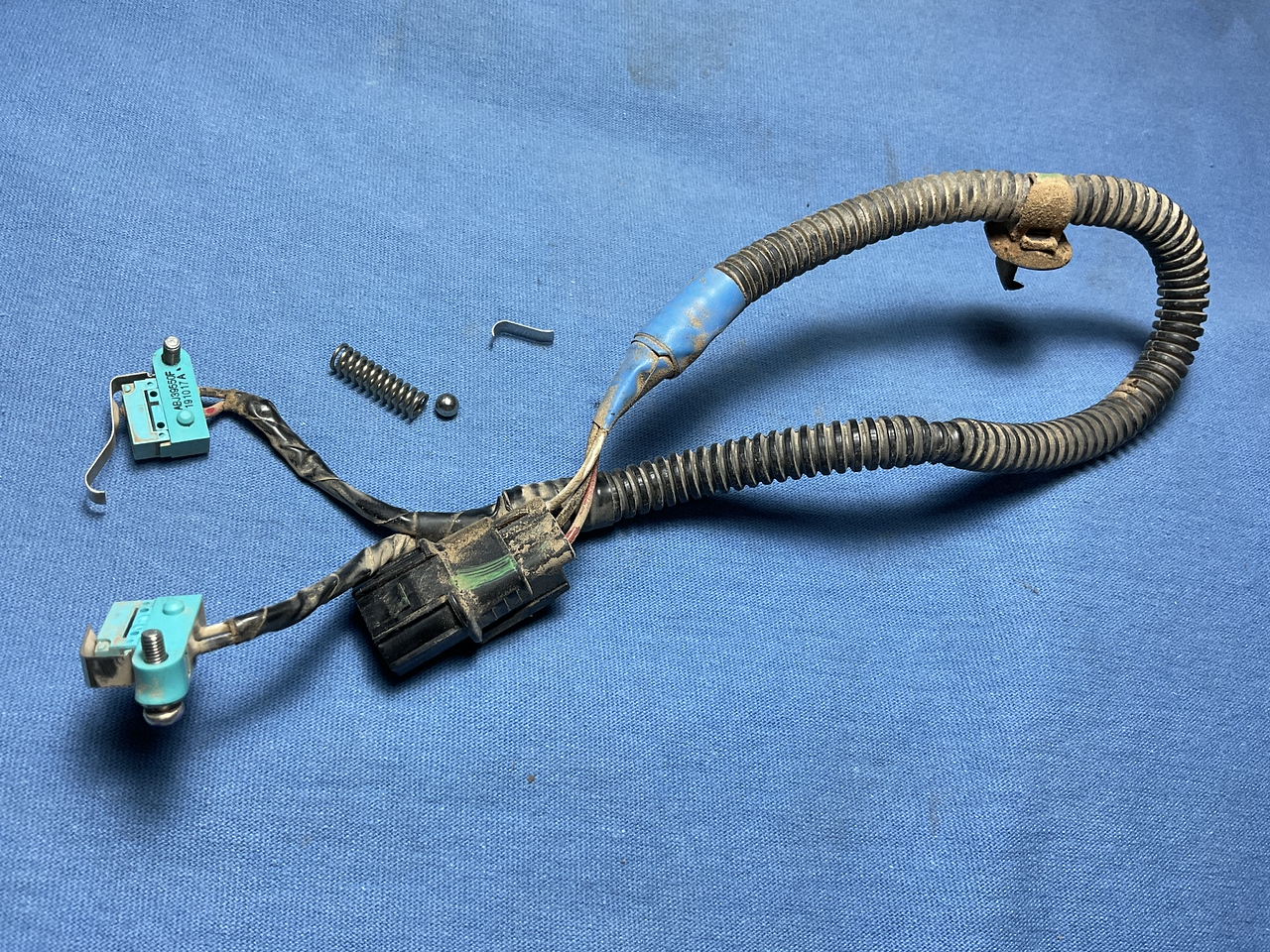

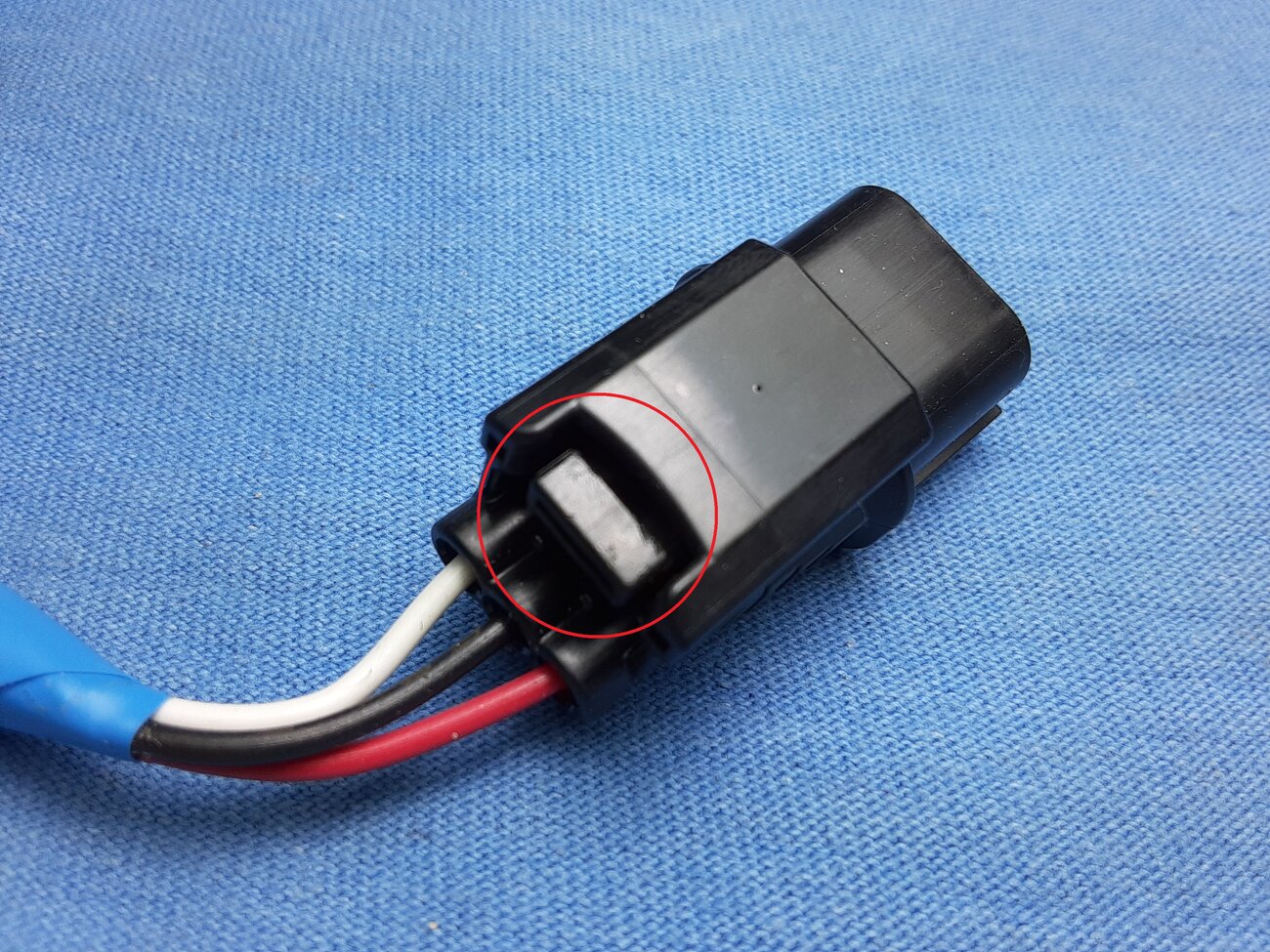

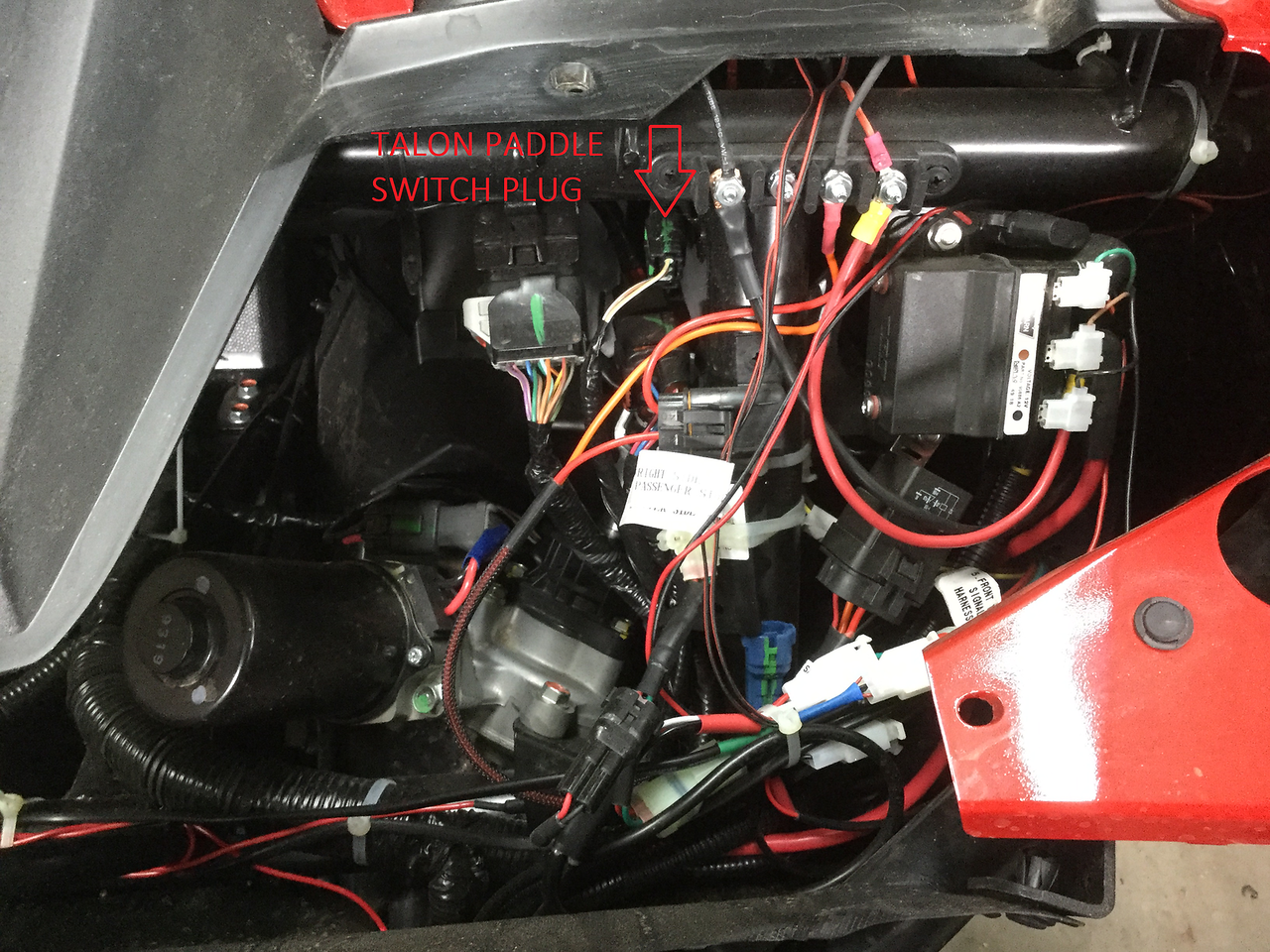

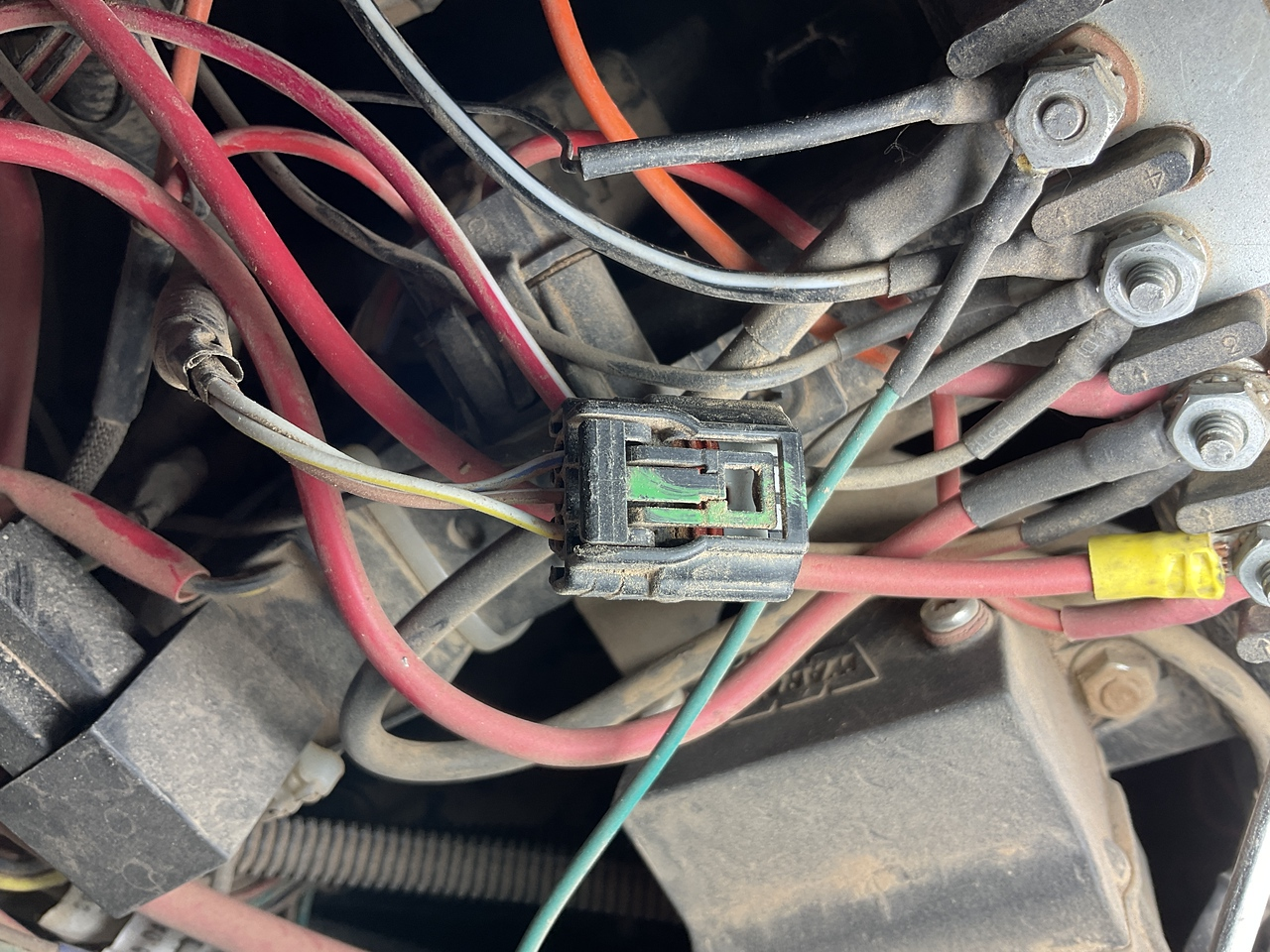

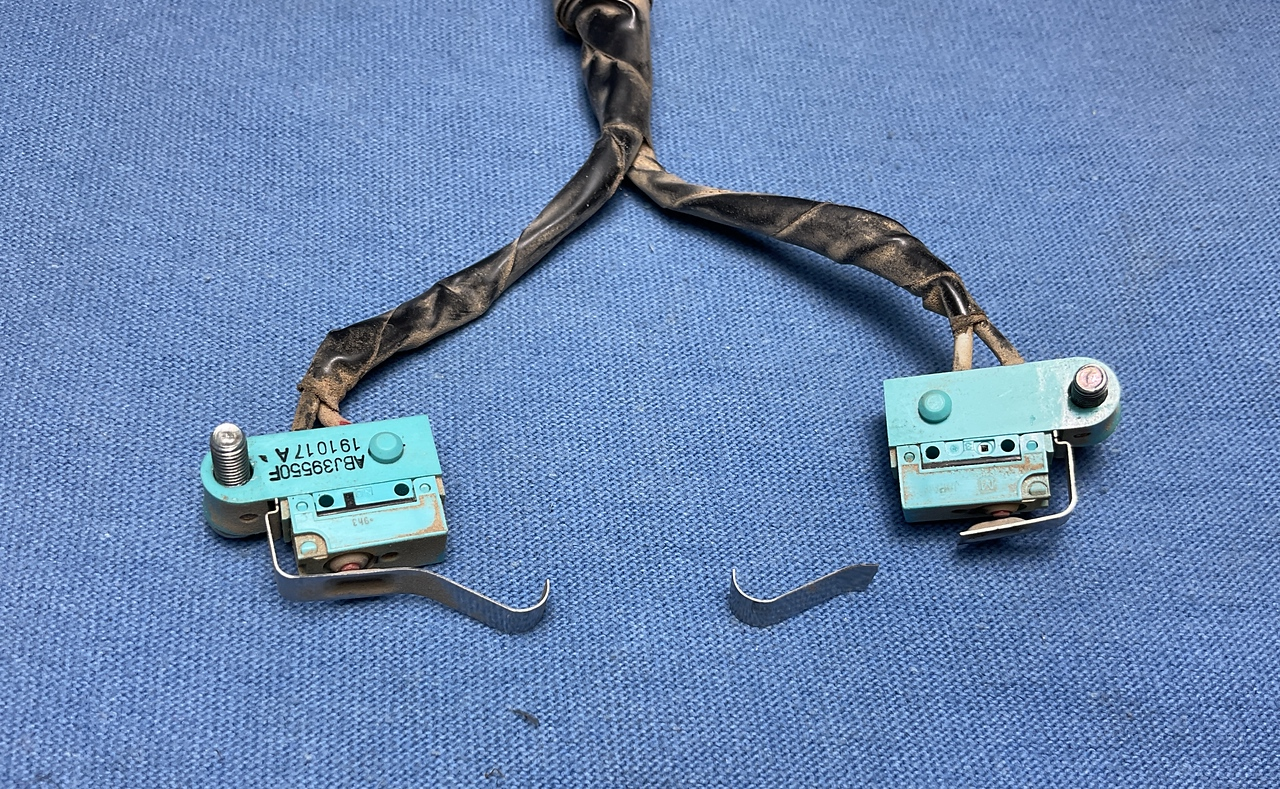

this is what I found.

this is what I found.

Those parts are on the new harness (~$27). Ignore the spring and ball bearing, they're part of the paddle itself and won't have to be removed (but I didn't know that).

Those parts are on the new harness (~$27). Ignore the spring and ball bearing, they're part of the paddle itself and won't have to be removed (but I didn't know that).