H

hondabob

Well-Known Member

Lifetime Member

Can this spot welding be accomplished with the driveshaft in the machine?

That picture should make every Talon owner want to inspect their yokes. 4 months before I'll see mine again. Great work Paul. I think your post should be added to first line of "What every Talon owner needs to know."More info for digestion. A fellow owner asked me to tack weld his driveline and what I discovered solidifies one of the theories about why/how these drivelines fail. This machine is a 2021 R and has less than 2,000 miles on it. Removing the driveline, I didn't feel anything out of the ordinary and everything looked and felt tight. BUT, upon further inspection after wiping off the dirt, I discovered the beginning of what I now believe is an eventual failure.

Honda puts paint marks on just about everything and the driveline is no exception. However, they only paint one cap on each end.

Rear yoke paint mark, everything looks normal...

View attachment 277636

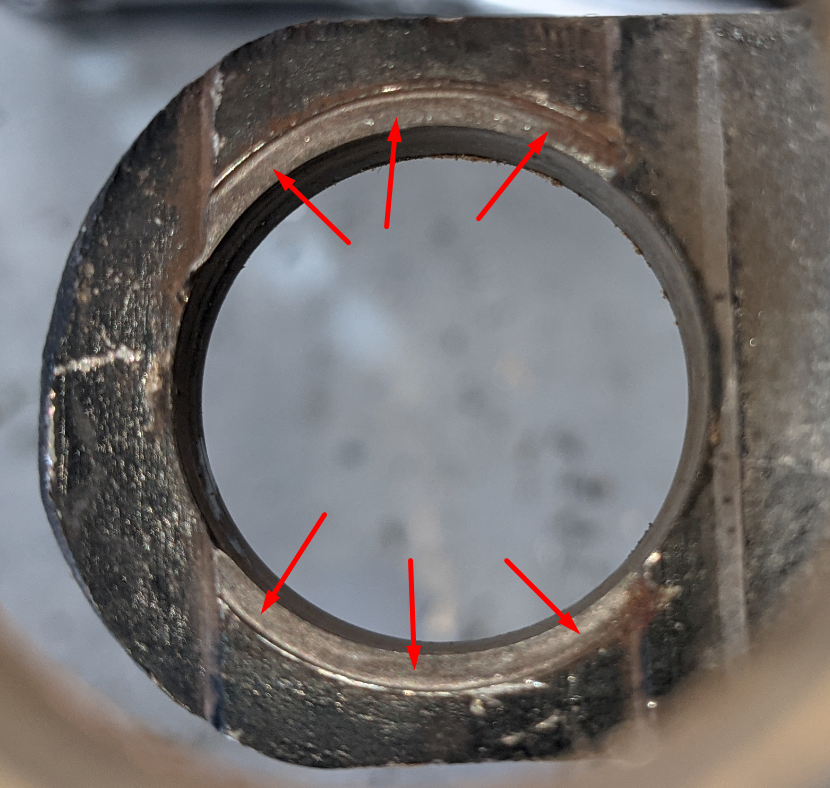

Front is a different story. The paint marked cup has rotated (maybe others too but hard to tell). Not sure if it is just 1/8 turn or if it has gone around a few times. The cup was still tight in the yoke and the clip had not worn the yoke (YET). The joint and yokes are still good so I tacked welded all 8 cups. Catastrophe averted!!!...

View attachment 277641

My opinion after all this is that the press fit is too loose and allows the cups to spin. Eventually, this wears the clips into the yokes and causes them to break or come out and the failure occurs.

HONDA, ARE YOU LISTENING!!!

I am with you on the search. I tried everything and was also unable to find out anything pertaining to U-Joint cup interference fit specs. That is why I decided to test a brand new driveline. This thread is pretty long so you may have missed this post...That picture should make every Talon owner want to inspect their yokes. 4 months before I'll see mine again. Great work Paul. I think your post should be added to first line of "What every Talon owner needs to know."

Maybe I don't know how to word Google search well enough. I just spent a couple hours looking for the interference fit for ANY universal joint caps. Couldn't find anything. How can a problem be analyzed without some specs? I also tried to contact Spicer for a spec. Forget contacting them unless you have a website and company name. You're not worth their time I guess.

Nope. The problem isn't the joints, they are high quality sealed joints and last a long time as long as the yokes are tight and don't allow the cups to spin. Problem is with the yokes.Does anyone make a replacemant aftermarket driveline that has spicer or moog joints? Should be easy to put one together for a fab shop.....

Allegedly the problem is only on the two seater….I will be checking my 2020 X4LV soon. I cant imagine Honda sources different yokes for 2 and 4 seaters but I haven't seen anyone complain about the X4 yet. Am i going to be the first?

The 4 seater has 2 shorter drivelines, 3 joints and a center carrier bearing. The only shared part appears to be the front yoke. Everything else is different, even the connection at the sub-trans.I will be checking my 2020 X4LV soon. I cant imagine Honda sources different yokes for 2 and 4 seaters but I haven't seen anyone complain about the X4 yet. Am i going to be the first?

Paul I know you have done a tremendous amount of work testing. I am back to my Talon finally and ready to inspect it. While thinking about welding the caps I wondered about another dimension on the yokes. How much end play is there on the journal cross? If there is too much end play, could that cause hammering on the clips also? I wouldn't think it could be a problem, but if they can't get the bore fit right. If I remove my snap rings and tack weld the caps, could they possibly need to be positioned different than where the snap rings would place them?I am with you on the search. I tried everything and was also unable to find out anything pertaining to U-Joint cup interference fit specs. That is why I decided to test a brand new driveline. This thread is pretty long so you may have missed this post...

Talon Front Driveline Woes

For future reference...... To remove the left side bolt on the front DS loop all you need to do is use a 1/4" drive socket, 1/4" drive swivel and 1/4" drive 3" extension connected to a 3/8" drive ratchet. Pry the floor back ever so slightly and it fits in there from the top. Easy peasy.hondasxs.com

The new driveline I tested has zero end play. They yoke spread and outside clip distance were the same (this is normal).Paul I know you have done a tremendous amount of work testing. I am back to my Talon finally and ready to inspect it. While thinking about welding the caps I wondered about another dimension on the yokes. How much end play is there on the journal cross? If there is too much end play, could that cause hammering on the clips also? I wouldn't think it could be a problem, but if they can't get the bore fit right. If I remove my snap rings and tack weld the caps, could they possibly need to be positioned different than where the snap rings would place them?

I can't tell from the pictures I've seen, if the clips are still in with the spot welds. I assume they are, but can't tell.The new driveline I tested has zero end play. They yoke spread and outside clip distance were the same (this is normal).

The problem with the stock yokes is they are too lose and the caps begin to spin and the clips wear into the yoke and eventually break or come out causing the cups to come out.

Tack welding the caps is not intended to hold them in, it is intended to keep the caps from spinning in the first place. If you can keep the cups from spinning, you will keep the clips from wearing the yokes and flying out and avoid the failure altogether.

The stock clips are left in place when the caps are tack weldedI can't tell from the pictures I've seen, if the clips are still in with the spot welds. I assume they are, but can't tell.

I will take my drive shaft out to weld it because I'm not a confident welder, I'm retired and have time, and I can better inspect their condition. But while I was installing a front camera yesterday, I looked down at the drive shaft and wondered why a better welder couldn't stretch down in there and spot weld the caps. I've read many people have trouble removing from the bottom. I'm sure others have considered this, but I didn't read it where I was looking. Just a thought to consider.

Yes, you can weld the caps with the driveshaft in place, @Lil_Steve posted pics in post #82.I will take my drive shaft out to weld it because I'm not a confident welder, I'm retired and have time, and I can better inspect their condition. But while I was installing a front camera yesterday, I looked down at the drive shaft and wondered why a better welder couldn't stretch down in there and spot weld the caps. I've read many people have trouble removing from the bottom. I'm sure others have considered this, but I didn't read it where I was looking. Just a thought to consider.

Boundertom removed it in post #57. I'll attempt that first.Are you sure you want to take the driveshaft out to weld it? You pretty much have to pull the diff out to get the driveshaft out, and if your digging onto it that far I'd buy an RB3 billet rack and swap that in at the same time to avoid having to pull the diff out again if/when the stock rack breaks.

Thanks CID, I read that earlier. But I will remove mine for better inspection, and hopefully not need replacing.Yes, you can weld the caps with the driveshaft in place, @Lil_Steve posted pics in post #82.