I probably can't add much new information, but I thought I would relate my experience. I only have 837 miles on my Talon, but with all these reports of drive shaft failures, I knew I had to address this. I finally had time to work on it today. Fortunately, I do have a lift. Unfortunately, I did not have

@PaulF to help me do this job! I spent over 2.5 hours just getting the shaft out. I have Trail Armor skids, so it took a few minutes to get those off. The biggest hangup was the left bolt on the front drive shaft loop. I spent 45 minutes on that, using all of my words, to no avail. It must have been tightened to about 5 million ft-lbs!

I checked the Honda manual for their procedure, which starts with removing the LF floorboard. I turned to the page on removing the floorboard, and the first step is to remove the dash!!! You have got to be kidding, Honda! I finally used a 3/4" hole saw and cut a hole through the floor board above the bolt. I didn't get the hole in perfect alignment, but it was close enough to get the bolt out. It isn't a flat area, so If I can't get a plastic plug to fit, I think a piece of Gorilla tape will suffice. I didn't have the proper retaining ring pliers to remove the drive shaft clip. I do have a nice set of retaining ring pliers, so I improvised using a large set of retaining ring pliers with 90 degree tips, which worked OK. I do think I will buy the proper pliers. I unbolted the front diff, but I did not loosen the engine bolts as PaulF suggests. I got the shaft loose with no problem, but getting it out of the machine was a puzzle. I finally got it out by the RR wheel. I did have to remove the rear drive shaft loop also.

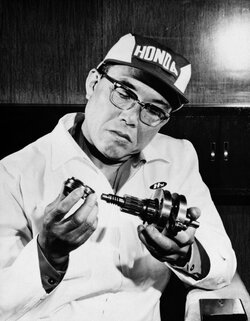

With the shaft out, I did a close inspection. There was no movement evident in any of the cups, so I got it in time. Cleaning the joints with a wire wheel, tack welding, and spray painting took all of about 20 minutes. Hopefully my drive shaft will now last a long time. I am very disappointed in Honda for allowing an issue like this to continue uncorrected. I will put it all back together tomorrow. Hopefully that will go uneventfully.

One of the pictures below shows two tack welds and how I connected the ground at each cup. The other picture shows the finished, painted job.

View attachment 274134 View attachment 274136