You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

T

So I just encountered the overheating issue this past weekend. Tough step climb low gear 4 wheel. Temp light comes on about 30 seconds before steam. Blew 2.5 quarts out. Cooled filled with water and worked fine rest of day. Just called my dealer this morning and literally Honda just came out with a tsb to reflash ECM module with updated program yesterday. I’ll get it in later in the week and let you know how it goes. Mines a 19’ p1k deluxe and have no heat issues first 200 miles. By the way the view from the top of Mount Harquahala west of Phoenix Az is amazing.

Smitty335

Well-Known Member

Lifetime Member

Supporting Member

Good to know!So I just encountered the overheating issue this past weekend. Tough step climb low gear 4 wheel. Temp light comes on about 30 seconds before steam. Blew 2.5 quarts out. Cooled filled with water and worked fine rest of day. Just called my dealer this morning and literally Honda just came out with a tsb to reflash ECM module with updated program yesterday. I’ll get it in later in the week and let you know how it goes. Mines a 19’ p1k deluxe and have no heat issues first 200 miles. By the way the view from the top of Mount Harquahala west of Phoenix Az is amazing.

farmtimpioneer

Wise Men Still Seek "Him"

Lifetime Member

Hello, Is This the same problem with the fan not coming on and You have to shut down and restart???So I just encountered the overheating issue this past weekend. Tough step climb low gear 4 wheel. Temp light comes on about 30 seconds before steam. Blew 2.5 quarts out. Cooled filled with water and worked fine rest of day. Just called my dealer this morning and literally Honda just came out with a tsb to reflash ECM module with updated program yesterday. I’ll get it in later in the week and let you know how it goes. Mines a 19’ p1k deluxe and have no heat issues first 200 miles. By the way the view from the top of Mount Harquahala west of Phoenix Az is amazing.

Took mine in for the new down load from Honda! Then I and called American Honda and asked for some one to call me about the problem and she was not so smart but told me that Honda has a fix or is still working on it so I feel like a guinea pig. After that the machine seems to start better and has a little more power! have 900 miles and it happened two times first about 300 miles and the second one about 600 miles. So it seems that I am dooooo for a third soon????

Smitty335

Well-Known Member

Lifetime Member

Supporting Member

Exactly why I won't have a Talon the first year out.Took mine in for the new down load from Honda! Then I and called American Honda and asked for some one to call me about the problem and she was not so smart but told me that Honda has a fix or is still working on it so I feel like a guinea pig. After that the machine seems to start better and has a little more power! have 900 miles and it happened two times first about 300 miles and the second one about 600 miles. So it seems that I am dooooo for a third soon????

T

Yes I believe so.Hello, Is This the same problem with the fan not coming on and You have to shut down and restart???

D

While in Colorado this past June & coolant level was fu

While running the mining trails in Colorado this past June, my 1000LE would overheat whenever I was pulling long steep trails above 10,000ft. The fan was running & the coolant level was fine. I tried high & low range with no appreciable difference (overheated in both). Just had to stop & let it idle for a while to cool-off then I’d continue to the top. Kind of a pain but it was nice to take a pee break!

ll

D

SAME issue. High altitude, long climb with tracks in the snow. Overheat and boil over 6 out of 8 rides. Dealer stumped so added override switch. This helped but still getting hot. This is in 10 degree weather. 9 mile ride to my cabin and made it twice in 8 attempts. Lots of money spent. Worked great in Moab. No issues.

hot in cold weather is lean tune condition, if you cant find anything else I would get A dobeck EJK, about the cheapest way to be able to control your fueling you can richen your tune for cold. I bought one for the can am because the low speed tunes are terrible on those, going slow would literally burn your feet in any kind of mud or things like that, before the tune I looked like one of those Harley guys feet on the edge of the floor boards, after I could wear sandles in the summer and all day in the mud park before the light come on. everyone else can ams that went had to wash out at lunch

advertisement

C

0

0860silverado

Well-Known Member

Lifetime Member

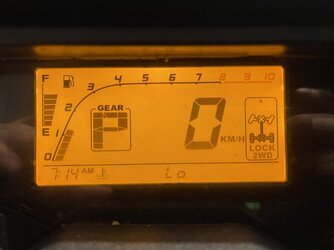

That's the icon showing that you are on the temp screen. Ii's normal. Where your screen says "Lo", that's where your coolant temp will show up. "Lo" means that the engine oil is not yet warm enough (really for the clutches) to be operated. Let it idle until you see one bar. Normal operating temp is two bars (out of the four total bars in the temp display). When the oil around the clutches is too cold, it'll drag the shafts along with them. Repeated shifting from park to reverse or drive before warming up the engine may result in premature sub-transmission damage.Hey guys mines come up with a similar issue I’m completely new to sxs it’s coming up with the small light along the bottom near the hr mark signalling temp is this normal or should I look into burping the radiator/ changing thermostat etc ?? Much help would be appreciated guys.

View attachment 287498

Last edited:

Honda fixed that a year or so ago. If it gets hot and the fan is not running it needs to get the recall flash done. It made my machine run way better. To fix on the trail just turn it off and restart, the fan should be running if it’s called for.

Unfortunately, this is the story across the entire world. Try to find ANYTHING that is not overly complicated. While I agree, things could be simpler, then people would be complaining that "the machine is "crude" or "not innovative". Heck, even flashlights are microprocessor controlled. Regardless, I love my HONDA and not going to buy anything else.I love my machine but it's just too complicated to be an offroad vehicle. This thing should've been a single clutch design with either a torque converter or centrifugal clutch between crank and clutch basket. Cooling fan operation should be like I mentioned couple posts ago. It's simple, it works perfectly, and it's almost bulletproof reliable.

Yes, I believe that HONDA could have used something like their ESP geared transmission from their older ATV's and scaled it up, but ANY auto-shifting manual gear transmission is going to be much more complex than a CVT. And after working for HONDA for 20 plus years, I know that this would not be "the HONDA Way". People are CONDITIONED to buy the latest greatest thing. I doubt that many "typical American consumers" would buy a "3rd world simple" SXS. This is exactly why I drive 20-50 year old cars and motorcycles, I can fix them. Unfortunately, those of us who feel this way are a dying breed.

There is a huge reason why ALL the other manufacturers of SXS vehicles have stayed with the proven CVT "technology" (if you can call it that), it is cheap, simple and it works quite well. These companies "innovate" in other ways. Don't misunderstand, I am not pushing the other stuff, I am not going to buy a belt driven machine, they have their own set of problems. The HONDA DCT works great, when it works and the cooling system works great when it works. Unfortunately, every connection, wire and component of the system must be near perfect if it is to continue to do so.

I have a DYNOJET PV3 on my 2016 1000-5D and people would be quite surprised how hot these engines run. On a blistering hot day and in a very slow, hard pull on a difficult trail, I have seen 242 degree coolant temps with the fan running constantly; the Pioneer never has boiled over, pushed coolant or anything else (although my anxiety levels were quite high). My fan is set to come on at 215 and off at 210, which is at a considerably lower temperature than stock. My fan now runs quite a bit more often, compared to the stock tune. In "Stock tune" the fan comes on at 223 and goes off at 221 and generally did not come on under "normal" conditions. Therefore, a stock machine runs just that much closer to boiling over, especially if there is ANY air in the system and the pressure cap is less than perfect at holding the correct pressure. In other words, that coolant is just enough hotter and has the potential to boil that much faster. All it takes is one small "void" or "bubble" in the cooling system at the thermostat or temp sensor and the entire system goes to hell in a hand basket.

People laugh at "hanging" the Pioneer from a tree, but getting that machine nose high, even by say 10 degrees will help bring all the bubbles to bleeder screw or the radiator cap, where they can escape from the system. After rebuilding my PIONEER 1000 engine, I did a little test. First I bled the system on a flat surface, until no more air escaped. I then put the front wheels on a set of ramps, allowed it to sit for a half hour or so. When it bled the system again, more air came out. So this lends credence to raising the front end to allow all of the air to move toward the top of the system.