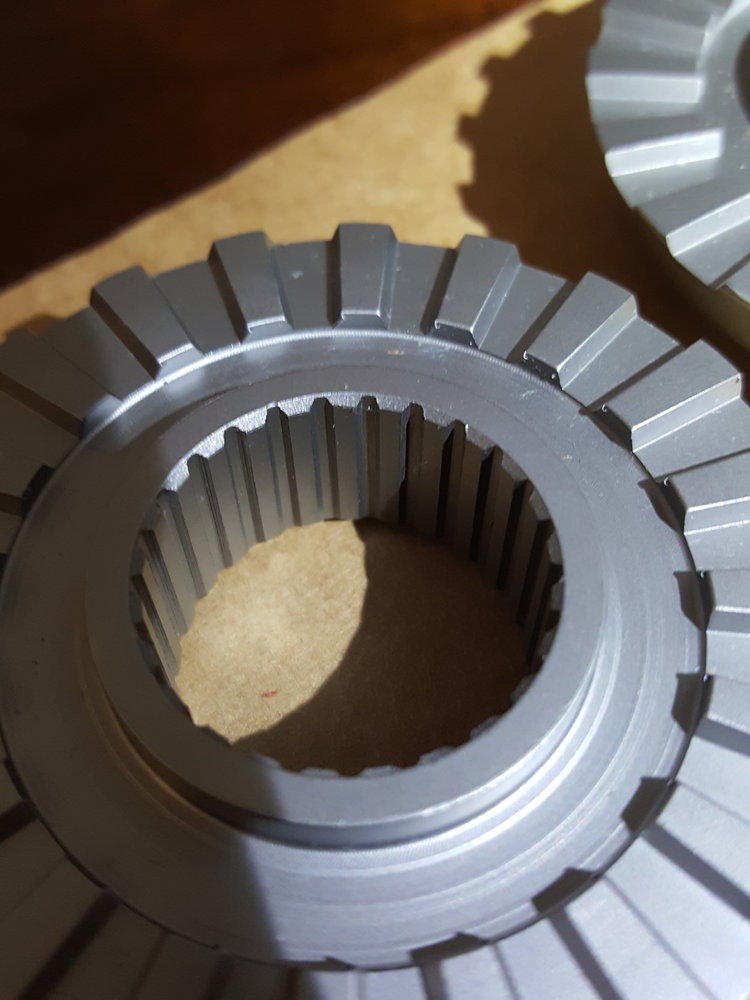

Locker installed. FYI, Torq-Mater sent an update to the installation procedure about the circlip.

Hi Folks!

We hope you are enjoying your new TORQ Locker! We will be providing technical support on the Honda SXS Forum as a Silver Level supporting partner, or you can always reach me directly via email (also the quickest way to reach us)

Cora@TorqMasters.com

This email is an official notice of an install manual update. Will update the installation manuals for all new orders to reflect the following:

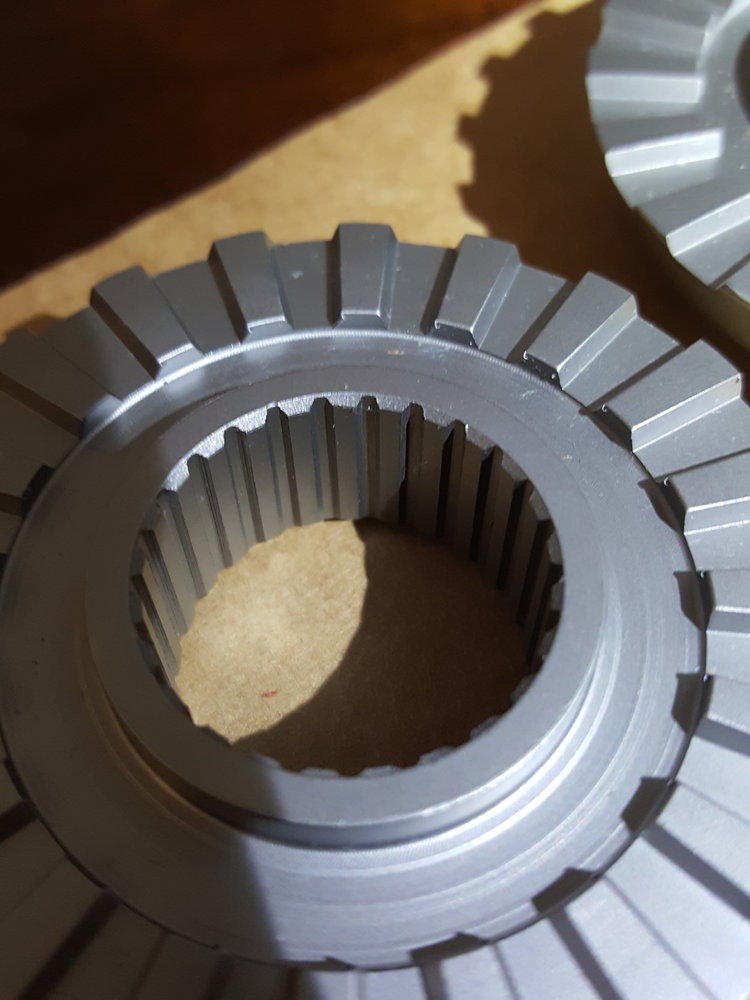

s.) Axle Re-installation - Remove the circlip from the differential side of the axle shaft assembly. Then tighten the circlip using pliers, reducing the diameter of the circlip. Reinstall circlip onto the axle shaft ensuring that the circlip is tight in the circlip recess in the axle shaft.

Reasoning behind the update:

One of our customers had difficulty removing his axle shaft after installing the TORQ Locker. After our review it was determined that his axle circlips were too loose, making the shaft very difficult to remove. Once his circlips were tightened he could install and remove the axle shaft as intended.

Please let me know if you have any questions, we are here to help!